You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Adventures in metalwork and machine restoration!

- Thread starter TFrench

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Trevanion

Greatest Of All Time

Ooo, those little Hardinge lathes are quite nice, they take 5C collects if I remember correctly.

Dead on! It's an HLV, not the updated HLV-H. 5C collets in the nose, and it has a couple of chucks. All the steady rests are with it, and the taper attachment. A lot of cleaning and getting rid of surface rust to do before I try running it. Hopefully the bed isn't too worn.

Sent from my SM-G973F using Tapatalk

Sent from my SM-G973F using Tapatalk

Now that is a very nice find indeed. Hardinge had about the best bearings of this generation of machines. And you have a very complete set of accessories. Will watch the restoration with much interest.

Keith

Keith

AES

Established Member

Great looking bit of kit TF. Lucky b - - -er!

BTW, how is the name spoken please? Soft "e" (as in Gilbert Harding) or with an "e" ("dingy")?

And while we're at it, how do you say GIB STRIP please? "Jib" (as in that thing on a sailing boat) or "Gib" (as in the Bee Gees)? (Often "argue" with a mate about that one - I say "Barry Gib").

Either way, looking forward to seeing this one "done up". Will it be a keeper TF?

BTW, how is the name spoken please? Soft "e" (as in Gilbert Harding) or with an "e" ("dingy")?

And while we're at it, how do you say GIB STRIP please? "Jib" (as in that thing on a sailing boat) or "Gib" (as in the Bee Gees)? (Often "argue" with a mate about that one - I say "Barry Gib").

Either way, looking forward to seeing this one "done up". Will it be a keeper TF?

Trevanion

Greatest Of All Time

AES":3lpe10nb said:BTW, how is the name spoken please? Soft "e" (as in Gilbert Harding) or with an "e" ("dingy")?

I would say like a hinge, "Hard-inge".

Gib. Jibs are for weirdos and Scandinavians.

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£19.46 (£3.89 / count)

£19.99 (£4.00 / count)

Stealth Lite Pro FFP3 Face Masks UK Certified Dust Mask. 99.99% particle filtration, air filter reusable face mask. FFP3 Mask -7 day use per Construction, Woodworking, DIY and Welding Mask

Amazon.co.uk

£26.99 (£1.35 / count)

VEVOX® FFP2 Dust Mask - Set of 20 - Valved Face Masks - Respirator - Protection e.g. for Construction, Building Work, Sanding, Woodworking, Fine Dusts, Aersoles or Particles

SLSK Ventures GmbH (UK)

Take it you saw it on ebay? I saw it go on a while ago and thought it looked a nail. It came back up in suggested items and I looked closer and realised it was more a case of terrible photography than rust. Then I realised just how many bits were with it and I figured that even if it was beyond repair I wouldn't lose out. Showed a friend on instagram and he agreed, so I did the deal. The toolpost is an original swiss multifix, which is a bonus!MusicMan":2k3np178 said:Now that is a very nice find indeed. Hardinge had about the best bearings of this generation of machines. And you have a very complete set of accessories. Will watch the restoration with much interest.

Keith

I'd love it to be a keeper - it really is a special thing. Something will have to give though - there's just not enough room at work for another big machine. It's a lot bigger than I expected actually - the chip pan goes back a long way to accomodate the taper attachment I think. I'm thinking I might sell the shaper, as realistically everything I can do on that can be done with a Deckel. I'll do some measuring and see if I can make it work.

Ditto to Trevanion on pronunciation!

Soft g in Hardinge, definitely.

I didn't see that on eBay actually. I've stopped looking at lathes so I wouldn't be tempted! And I love my Boleys. However, that is a very capable machine indeed. The accessories are probably worth as much as the lathe. It is cool that it has separate carriage drive and screw cutting drive. I would try to shoehorn it all in if you possibly can!

The main thing to check on is the wear on the bed near the chuck, as you know. It's very difficult to adjust the carriage properly if there is uneven wear. Even then it is not terminal. I had one of my Boleys reground (in Birmingham) as it was so bad. This is costly but gives a new lease of life.

Good luck!

I didn't see that on eBay actually. I've stopped looking at lathes so I wouldn't be tempted! And I love my Boleys. However, that is a very capable machine indeed. The accessories are probably worth as much as the lathe. It is cool that it has separate carriage drive and screw cutting drive. I would try to shoehorn it all in if you possibly can!

The main thing to check on is the wear on the bed near the chuck, as you know. It's very difficult to adjust the carriage properly if there is uneven wear. Even then it is not terminal. I had one of my Boleys reground (in Birmingham) as it was so bad. This is costly but gives a new lease of life.

Good luck!

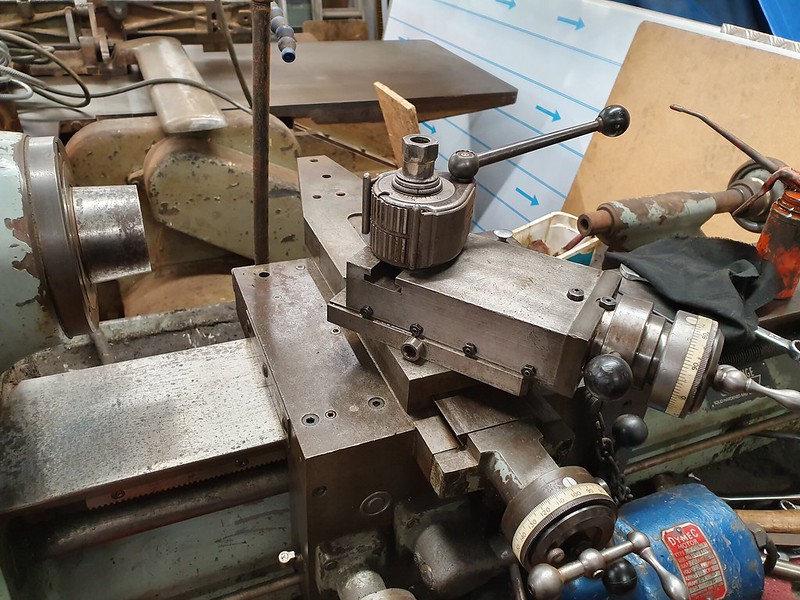

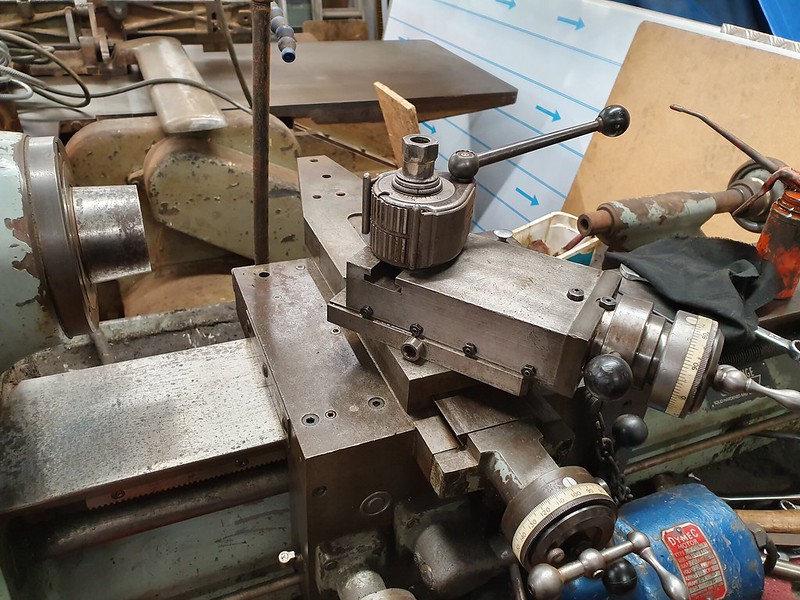

Been going to work early whenever we're in the yard so I can crack on with this. Finally starting to see some progress. Bed is cleaned off, I can select all the gears, I've had the cross slide and compound completely to pieces to clean them all out. 60 odd years of crud and its all a bit sticky!

I had to deploy the big guns on the handles - the graduated dial is plastic so I couldn't just hit it with the mapp torch! Induction bolt heater - this thing is fantastic. Got the handle to smoking hot in about 15 seconds and red shortly after, with no damage to the plastic next to it. Success.

Hardinge compound

Hardinge compound

This is the carriage all put back together - I will still take it off completely to measure the bed but if its all put back together I can't forget how it goes. This thing is seriously complex! You can see the tailstock in the background, thats how all of these parts looked when I started. Lots of WD40 and scotchbrite is the key!

Hardinge cross slide

Hardinge cross slide

I've taken all the extra bits home so I've got something to work on when I get time. It has the original taper attachment which is really nice. Endless changewheels too - there's more still at work. Not sure if they all belong to it. Think they'll get the evaporust treatment. There was also a load of R8 collets and a bridgport horizontal arbor support with it, along with some chucks that are way too big. I'll flog all of those as I've no use for them.

Hardinge accessories

Hardinge accessories

Lastly - tonights job. Cleaned all the 5C collets that came with it on the brass wire wheel. They were really rusty on the fronts.

Hardinge collets

Hardinge collets

I had to deploy the big guns on the handles - the graduated dial is plastic so I couldn't just hit it with the mapp torch! Induction bolt heater - this thing is fantastic. Got the handle to smoking hot in about 15 seconds and red shortly after, with no damage to the plastic next to it. Success.

Hardinge compound

Hardinge compoundThis is the carriage all put back together - I will still take it off completely to measure the bed but if its all put back together I can't forget how it goes. This thing is seriously complex! You can see the tailstock in the background, thats how all of these parts looked when I started. Lots of WD40 and scotchbrite is the key!

Hardinge cross slide

Hardinge cross slideI've taken all the extra bits home so I've got something to work on when I get time. It has the original taper attachment which is really nice. Endless changewheels too - there's more still at work. Not sure if they all belong to it. Think they'll get the evaporust treatment. There was also a load of R8 collets and a bridgport horizontal arbor support with it, along with some chucks that are way too big. I'll flog all of those as I've no use for them.

Hardinge accessories

Hardinge accessories Lastly - tonights job. Cleaned all the 5C collets that came with it on the brass wire wheel. They were really rusty on the fronts.

Hardinge collets

Hardinge colletsEvaporust will work really well on the change gears, that's how I did mine on the Boley 3.

Cheers guys. Changegears are done. Evaporust worked its magic on most of them, but a couple were too big for the tub. Also got the chuck stripped and rebuilt. Ultrasonic was great for this, got all the crud out of the hard to reach bits. Pic here of it nestled between the 2 other chucks that came with the lathe. No idea why they were with it, the big one wouldn't even clear the bed! Getting them cleaned up and ready for ebay while it's cheap listing!

Does my chuck look big in this?

Does my chuck look big in this?

Does my chuck look big in this?

Does my chuck look big in this?Finally finished a project that's been eating away at me since I started it (posted about it on 26th July last year...  ) - the Dickson toolpost for the big lathe. I've got lots of lathe jobs to do and I've been putting them off because shimming tools in the old 4 way holder drives me insane.

) - the Dickson toolpost for the big lathe. I've got lots of lathe jobs to do and I've been putting them off because shimming tools in the old 4 way holder drives me insane.

We left off here, with the new stud:

Finished

Finished

I made a new T- nut (spot the glaring mistake :lol: ) and the top nut

Added a bar handle:

It's been a really fun little job, and it'll make the lathe much more usable. Probably a lot more of these projects coming, with all the enforced coronavirus workshop sentence

We left off here, with the new stud:

Finished

FinishedI made a new T- nut (spot the glaring mistake :lol: ) and the top nut

Added a bar handle:

It's been a really fun little job, and it'll make the lathe much more usable. Probably a lot more of these projects coming, with all the enforced coronavirus workshop sentence

Nice job there. I love the Dickson tool post. Now, I must get on and do the same as you instead of the badly fitting threaded rod and a pile of washers!

kevinlightfoot

Established Member

I love this thread!Come on lads give us more of your endeavours,I think they are more interesting than the woodwork stuff .Is there a site which you can reccomend with more like this? Keep it up best regards Kevin.

Trevanion

Greatest Of All Time

kevinlightfoot":1xl0hvou said:Is there a site which you can reccomend with more like this?

Instagram is where all the cool kids are at 8)

Like Trevanion says, lots of people doing very cool things on instagram. I still like the forum format though, you can get a much more in depth discussion on stuff, without the moron opinions on social media. I don't put pics of all the stuff I get up to on here as I've been moaned at in the past for using the forum as advertising. Never mind the fact no one on here has ever once bought any machinery from me :lol:

I've been working on the lathe all day today, making parts for my big pillar drill. I'm catching up on all the projects I've had kicking around my head for years, I love it! Every cloud and all that.

I've been working on the lathe all day today, making parts for my big pillar drill. I'm catching up on all the projects I've had kicking around my head for years, I love it! Every cloud and all that.

Trevanion

Greatest Of All Time

What size is that? 4 inches?

I was turning some 3" ally the other day which was the biggest thing I've stuck in the machine, except for the 10" handwheel I turned the outside diameter true on a few days prior but I don't think that really counts.

I need to make another post on IG of what I've been doing, just haven't had the time/can't be arsed :lol:

I was turning some 3" ally the other day which was the biggest thing I've stuck in the machine, except for the 10" handwheel I turned the outside diameter true on a few days prior but I don't think that really counts.

I need to make another post on IG of what I've been doing, just haven't had the time/can't be arsed :lol:

Similar threads

- Replies

- 24

- Views

- 869

- Replies

- 7

- Views

- 1K