adzeman

Established Member

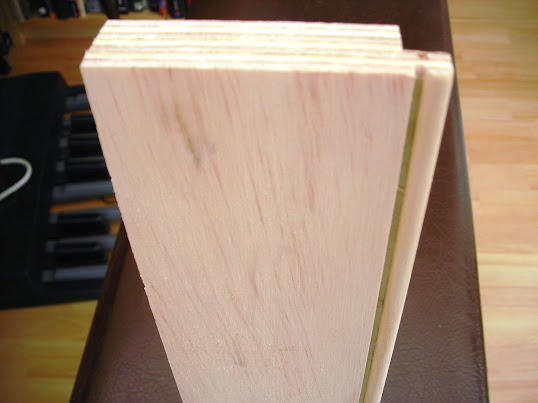

Three down one to go. Following the Homebase theme I am calling this style the Norfolk.

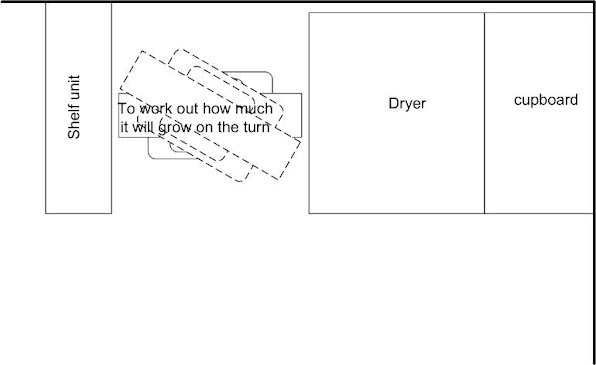

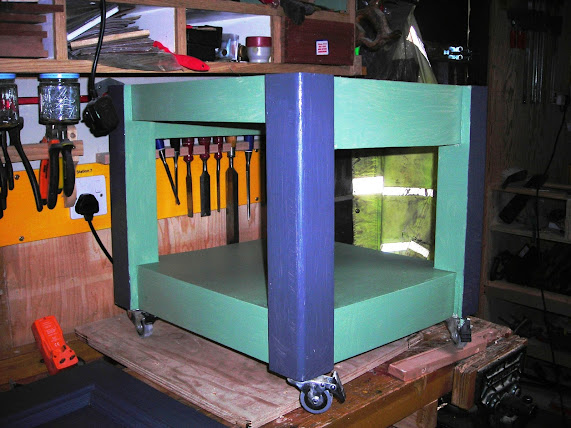

Not wanting my planer/thickmesser stand just to be an empty box I toyed with the various schemes to utalise the centre space.

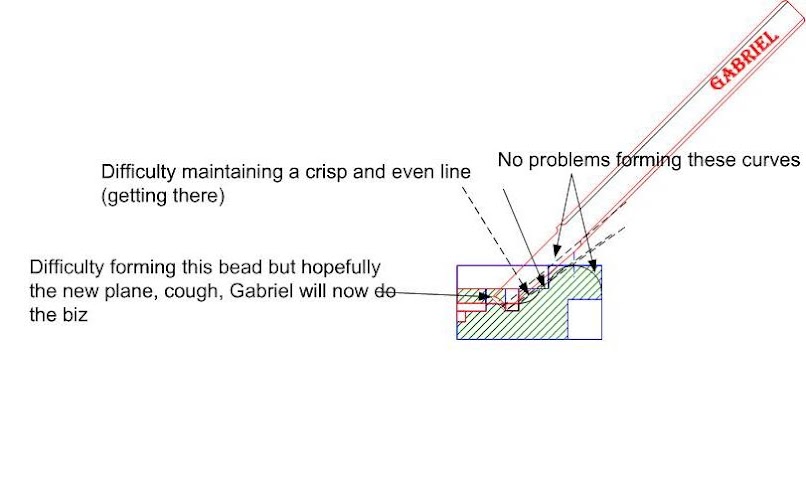

The intention to store boxes of screws but abandened this idea when I found the space fits my chop saw so only one door needs to open the others can be fixed. Now my router lift is working I may try my han at a bolection mould.

Not wanting my planer/thickmesser stand just to be an empty box I toyed with the various schemes to utalise the centre space.

The intention to store boxes of screws but abandened this idea when I found the space fits my chop saw so only one door needs to open the others can be fixed. Now my router lift is working I may try my han at a bolection mould.