Hi

I don't have any WIP shots, sorry.

As a lifelong DIYer this is my first real foray into proper hardwood furniture. The size was dictated by the wood I had available which was just odds and ends I had been given.

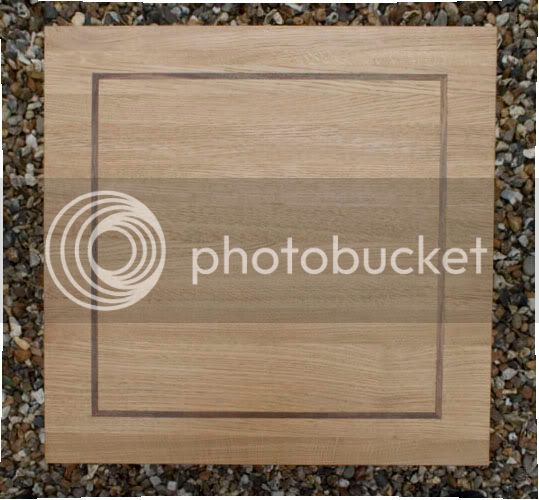

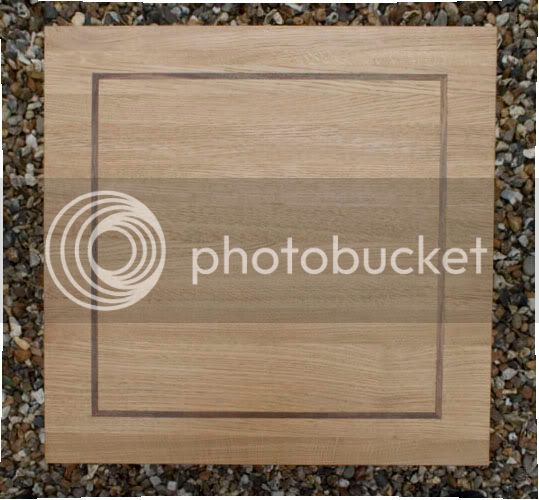

The table stands 520mm tall, the top is 460mm square.

Made of oak with the rails made of European oak. The inlay in the top is walnut.

The legs are tapered and the rails are morticed into the legs with twin mortices.

You cannot see easily in the photographs but the table top is chamfered under the edge back 50mm so the top is 20mm thick to the rails and 12mm at the edge.

I did have a problem with the finish on the top. The oak kept tearing out, i finished with a cabinet scraper but still a little rough to the touch.

Overall I am pleased with the results.

Please don't be afraid to give comments, this is a learning curve for me and I would like to improve. One thing I do know is I need to get a shoulder plane as making the mortices fit perfectly without one was quite difficult.

Mick

I don't have any WIP shots, sorry.

As a lifelong DIYer this is my first real foray into proper hardwood furniture. The size was dictated by the wood I had available which was just odds and ends I had been given.

The table stands 520mm tall, the top is 460mm square.

Made of oak with the rails made of European oak. The inlay in the top is walnut.

The legs are tapered and the rails are morticed into the legs with twin mortices.

You cannot see easily in the photographs but the table top is chamfered under the edge back 50mm so the top is 20mm thick to the rails and 12mm at the edge.

I did have a problem with the finish on the top. The oak kept tearing out, i finished with a cabinet scraper but still a little rough to the touch.

Overall I am pleased with the results.

Please don't be afraid to give comments, this is a learning curve for me and I would like to improve. One thing I do know is I need to get a shoulder plane as making the mortices fit perfectly without one was quite difficult.

Mick