This thread reminded me I'd had the parts for a small chariot plane cut out & sitting on my bench for about 4 months or more. They were well-covered by other junk, which is partly why it had sunk off the screen!

. So I decided it was high time to finish it off, and the couple lessons I learned might have some relevance to this thread. This is my 4th or 5th split-sole plane now, & I'm definitely still on the learning-curve, as I discovered!

Lesson #1, is, if you are going to put something aside for a while, make sure you document any changes of plan that occurred. This plane was to have a long-ish toe & I'd got as far as splitting the sole & forming the tongue & groove joint, but not forming the bed bevel. I knew I'd decided to change the bed angle I'd drawn on my initial sketch from 15 to 19 degrees, & I had scribed the lines for the mouth bevel, so I reckoned they must be correct, so I went ahead and cut a series of hacksaw cuts to make little fillets that I could chisel out to get rid of the bulk of the waste. It was only when I made the guide-block (for the higher angle) and clamped it to my sole that I realised I'd been working to the lower bed angle, & hacksaw cuts went a bit far back. It meant that I had to file more away from the front than I wanted, to to get a clean bed. Lesson #2 - always check & re-check!

On a rough test, holding the blade in position, it seemed ok; it looked like the mouth would be larger than planned, and allow little or no room to file the front & finesse it, as I would usually do after lapping the sole, but as long as I worked carefully, I reckoned it would be fine.

I didn't keep a lot of progress shots, sorry - I wasn't planning on showing the stages of the build, but here is the body with the D/Ts fitting & ready to pein. The tails are a good fit in their sockets, making them easier to fill, & most importantly, the two pieces of the sole are tight & straight:

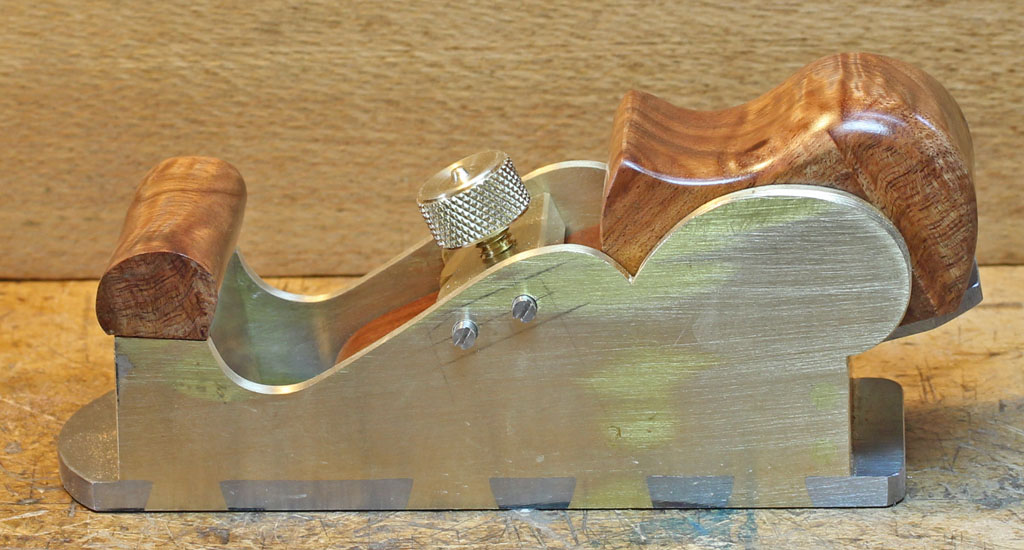

So we jump next to fitting the bridge & woodwork, always a bit tedious as any infill maker knows. The wedge/lever was simple enough, but the small over-stuffed infill for the front bun/scroll was rather small & hence very fussy to fit tightly:

Jumping forward another day & it was ready for lapping, & after getting the sole roughly flat, I put a blade in to check the mouth. Drat! It turned out quit a bit wider than my earlier check had indicated. Compare the new plane (right) with one that has a 'proper' mouth:

The light coming through the gap reflects off the blade bevel and makes both mouths look bigger than they are, but the one on the left is what I was aiming for (something between 0.2 & 0.5mm), while that on the right is more like 0.8mm. Lesson # 3 - check more carefully next time!

So I carried on lapping, and got it to the stage where I could give it a test-run. There's still a small low spot beside the mouth, where the front piece has depressed a bit under peining. It's not actually impinging on the mouth proper, and won't affect performance, but it's an annoying imperfection in an otherwise satisfactory assembly job:

The story hasn't ended too badly, it's a beaut little plane, and on fairly benign wood it had no problem dealing with some reversing grain. I spent far more time testing than was necessary, just for the pleasure of feeling it snick across the test piece & watching it throw out fluffy shavings:

Perhaps it was fate telling me I really needed a more 'general purpose' plane - the fine-mouthed thing shown above does have a tendency to choke if I get a bit enthusiastic with shaving thickness. Not sure why that is, the gap is actually bigger than the thickest shaving I would want to take, but quite a few of our hardwoods just have this tendency to pack in the mouth gap, despite there being what looks to me like adequate relief on the front side of the mouth.

I will probably add a screw adjuster, even though I'm just as happy to use the tippy-tap method, but I won't do that 'til I get a permanent blade for it (testing was done with a 'borrowed' blade). I was thinking of putting a PM-V11 blade in this one, as I've become rather fond of the stuff for its ability to cope with our absurdly hard woods. In the meantime, it goes into the tool cupboard & sea-trials start in earnest as soon as its new blade arrivese....

Cheers,

IW