Readers with long memories may know that I am the happy owner of a foot-powered fretsaw from the late nineteenth century, a Fleetwood No 3, made by the Trump Brothers before the family went off the rails and abandoned the idea of making woodworking tools  . I described it here and the job of getting it back into working order here.

. I described it here and the job of getting it back into working order here.

Since then I have mostly used it for removing the waste from dovetails, where it outperforms more modern fretsaws, I reckon.

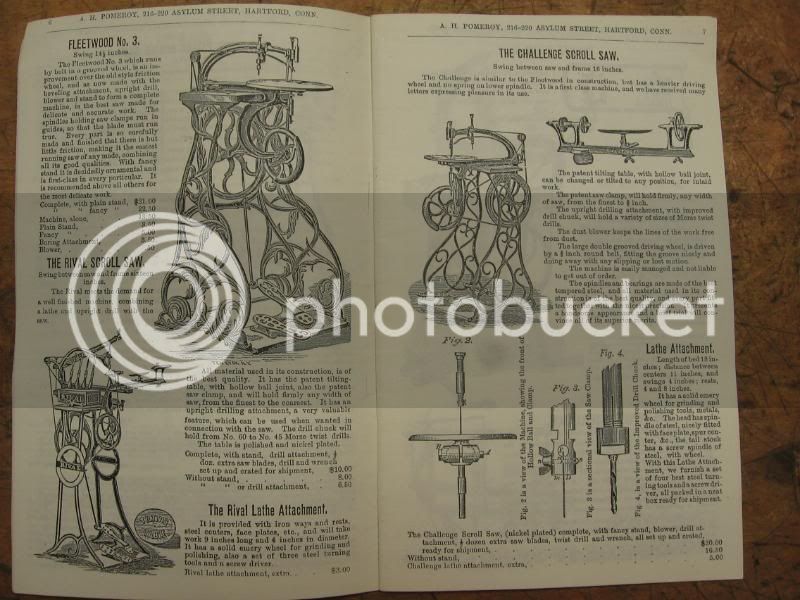

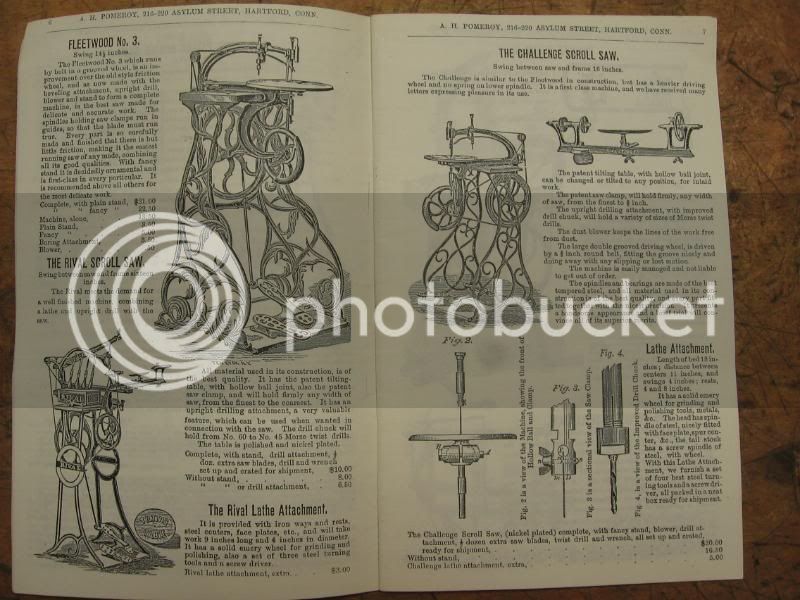

However, it has a flaw. Although the original purchaser had the good taste to choose the fancy stand over the plain, they didn't shell out the extra 50 cents for the blower attachment. You can just about glimpse it, forward of the drilling attachment, in this catalogue image posted on the Old Woodworking Machinery site here.

I've not found a proper picture of the blower anywhere but thought I would have a go at making one. It's been on my list of things to make for a while and once in a while I like the idea of pottering about with bits of old scrap in pursuit of something totally trivial but probably achievable.

This shows the top of the saw. The post above the saw goes up and down. There's a handy threaded hole where the blower goes. I need to find a pump, mount it and link it to the moving post.

Some time ago a mixed box of tools came my way which included this scruffy old blowlamp.

I'm no fan of blowlamps polished up as ornaments and I don't fancy burning the house down with pressurised petrol leaking past old perished rubber seals so I am never going to do anything with it. However, this pumpy bit looks useful:

Indeed, it's like a miniature bike pump, with a leather cup washer inside and a screw in nozzle/valve affair at the end. Ideal!

I considered making something out of metal to hold the pump but decided that wood would be easier and probably ok. So I bored a clearance hole in an offcut of walnut

and then carefully reamed out one side a little bit.

The slight enlargement on the close grained wood was just enough for the fine thread at the middle of the pump to fit in nice and tight. After adding an extra hole and trimming the surplus away on the bandsaw, I got it mounted nicely on the saw.

Sharp eyed readers will have noticed that the top of the pump is about 2¼" inches above the top of the moving shaft on the saw.

I noticed that too, so it was off to the lathe to make an extension.

I put some ½" brass bar in the chuck, turned the tip down to size and knurled what was to become a fixing knob.

I drilled one end ready to tap a matching thread and the other so it would fit on the post.

To hold it on the post, I made a flat on the side

and drilled and tapped it, to take a screw with its tip filed to a point, to sit in the groove that's already there.

I also tapped the top, to fit the brass knob.

To direct the air down to the work I used some 6mm brass tube, bent round and flattened at the end. I drilled out the bottom of the valve which was on the end of the pump, to a size just above 6mm. I filed some grooves around the pipe, to hold some tiny O-rings.

With a little vaseline, this made an airtight but swivelable connection.

I used a bit of leather from an old belt to join the top of the pump to the top of the extension post, as you can see in this view of the finished article:

So does it work?

Well, this cut was made with the blower disconnected. The sawdust is obscuring the pencil line in the old, annoying way:

But with the blower in use, the dust is all shifted away from the line and I can see where I ought to be cutting - success!

I should say that this is a slightly shortened account, missing out a few failed alternative details, and I didn't stop to photograph absolutely everything, but overall I'm happy with it.

The saw runs just as sweetly as before and I can get some gentle indoor exercise on a wet and windy day .

.

Since then I have mostly used it for removing the waste from dovetails, where it outperforms more modern fretsaws, I reckon.

However, it has a flaw. Although the original purchaser had the good taste to choose the fancy stand over the plain, they didn't shell out the extra 50 cents for the blower attachment. You can just about glimpse it, forward of the drilling attachment, in this catalogue image posted on the Old Woodworking Machinery site here.

I've not found a proper picture of the blower anywhere but thought I would have a go at making one. It's been on my list of things to make for a while and once in a while I like the idea of pottering about with bits of old scrap in pursuit of something totally trivial but probably achievable.

This shows the top of the saw. The post above the saw goes up and down. There's a handy threaded hole where the blower goes. I need to find a pump, mount it and link it to the moving post.

Some time ago a mixed box of tools came my way which included this scruffy old blowlamp.

I'm no fan of blowlamps polished up as ornaments and I don't fancy burning the house down with pressurised petrol leaking past old perished rubber seals so I am never going to do anything with it. However, this pumpy bit looks useful:

Indeed, it's like a miniature bike pump, with a leather cup washer inside and a screw in nozzle/valve affair at the end. Ideal!

I considered making something out of metal to hold the pump but decided that wood would be easier and probably ok. So I bored a clearance hole in an offcut of walnut

and then carefully reamed out one side a little bit.

The slight enlargement on the close grained wood was just enough for the fine thread at the middle of the pump to fit in nice and tight. After adding an extra hole and trimming the surplus away on the bandsaw, I got it mounted nicely on the saw.

Sharp eyed readers will have noticed that the top of the pump is about 2¼" inches above the top of the moving shaft on the saw.

I noticed that too, so it was off to the lathe to make an extension.

I put some ½" brass bar in the chuck, turned the tip down to size and knurled what was to become a fixing knob.

I drilled one end ready to tap a matching thread and the other so it would fit on the post.

To hold it on the post, I made a flat on the side

and drilled and tapped it, to take a screw with its tip filed to a point, to sit in the groove that's already there.

I also tapped the top, to fit the brass knob.

To direct the air down to the work I used some 6mm brass tube, bent round and flattened at the end. I drilled out the bottom of the valve which was on the end of the pump, to a size just above 6mm. I filed some grooves around the pipe, to hold some tiny O-rings.

With a little vaseline, this made an airtight but swivelable connection.

I used a bit of leather from an old belt to join the top of the pump to the top of the extension post, as you can see in this view of the finished article:

So does it work?

Well, this cut was made with the blower disconnected. The sawdust is obscuring the pencil line in the old, annoying way:

But with the blower in use, the dust is all shifted away from the line and I can see where I ought to be cutting - success!

I should say that this is a slightly shortened account, missing out a few failed alternative details, and I didn't stop to photograph absolutely everything, but overall I'm happy with it.

The saw runs just as sweetly as before and I can get some gentle indoor exercise on a wet and windy day