You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

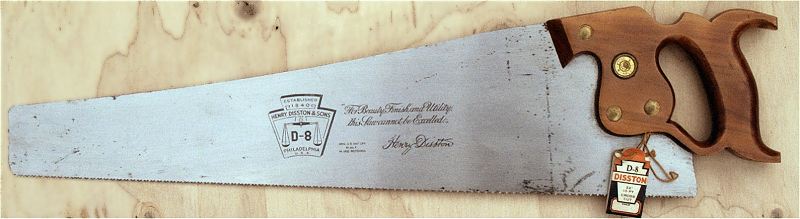

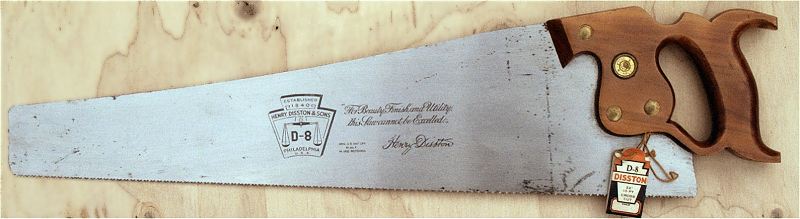

£2 Carboot Diston Refurb

- Thread starter Richard T

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

bugbear

Established Member

marcros":1cis00bn said:which is the easier to learn sharpening on- cross cut or rip- I have one of each on the wall that I need to do one of these days. Is removing the handle SOP, or is it "avoid if it is tight"?

RIP is much simpler, since the rake is (or can be) 0 degrees, and the fleam is always 0 degrees, so you have less complexity to try to think about and maintain.

Larger teeth (within reason) are also easier to see, and small errors in filing have less effect (a "small" error in filing on a 20 TPI dovetail saw can completely remove a tooth!)

I would always leave the handle on unless it absolutely needs to be removed. It is likely that either the plate, handle or screws will be damaged during removal, requiring yet more work and skill to get it all back together. Difficulty cleaning the plate near the handle is the price you have to pay for this.

BugBear

Cheshirechappie

Established Member

Excellent job, Richard. Splendid refurbishment, and a really good investment!

There's a small tip when refurbishing longsaws. Many of them seem to suffer from excessive sharpening in the middle of the blade, leading to a distinct hollow in the toothline (a hump in the toothline is not so bad - indeed, some saws were offered new with a 'breasted toothline').

Taking this hollow out can be a problem. I had one saw in which I jointed the ends until the tooth profiles had almost disappeared, but the middle teeth were untouched. I stopped jointing at this point, and recut the tooth profiles at the heel and toe, then jointed again, then recut profiles again. A straight wooden stick (doesn't have to be to split-thou accuracy) makes a good straightedge (tip copyright Bugbear, and it's a good one - a 2" x 1/2" or so stick is far easier to wield than a steel straightedge, and won't damage teeth).

There's a small tip when refurbishing longsaws. Many of them seem to suffer from excessive sharpening in the middle of the blade, leading to a distinct hollow in the toothline (a hump in the toothline is not so bad - indeed, some saws were offered new with a 'breasted toothline').

Taking this hollow out can be a problem. I had one saw in which I jointed the ends until the tooth profiles had almost disappeared, but the middle teeth were untouched. I stopped jointing at this point, and recut the tooth profiles at the heel and toe, then jointed again, then recut profiles again. A straight wooden stick (doesn't have to be to split-thou accuracy) makes a good straightedge (tip copyright Bugbear, and it's a good one - a 2" x 1/2" or so stick is far easier to wield than a steel straightedge, and won't damage teeth).

Richard T

Established Member

Very good tip CC.

I was lucky with this one - it wasn't too bad in any department. If it had been as bad as some I have rescued in the past I'd still be at it now; so it's not always that easy or quick.

For the purpose you mention I have a yardstick that I use a rule ....

I was lucky with this one - it wasn't too bad in any department. If it had been as bad as some I have rescued in the past I'd still be at it now; so it's not always that easy or quick.

For the purpose you mention I have a yardstick that I use a rule ....

TobyC

Established Member

How long is the blade Richard, 22''?

Toby

Toby

Richard T

Established Member

Thanks Toby for your inquisitions - Without you I would have never realised it was so old.

It's 26".

It's 26".

£238.91

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£16.59

£25.00

Woodworking Joinery by Hand: Innovative Techniques Using Japanese Saws and Jigs

Amazon.co.uk

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£12.50 (£1,250.00 / kg)

£14.45 (£1,445.00 / kg)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

TobyC

Established Member

This is where it gets interesting. Was the label screw I posted the same as the one on your saw...does it say Disston?

If so then It's a D-8.....with a panel saw handle, like this.....

From http://www.disstonianinstitute.com/d8page.html

The problem is...panel saws are 24'' or less.

So, you have a 26'' handsaw with a panel saw handle. And it hasn't been altered or redrilled.

Are you sure it's a 26'' blade? If so, I've never heard of or seen one before!

Toby

If so then It's a D-8.....with a panel saw handle, like this.....

From http://www.disstonianinstitute.com/d8page.html

The problem is...panel saws are 24'' or less.

So, you have a 26'' handsaw with a panel saw handle. And it hasn't been altered or redrilled.

Are you sure it's a 26'' blade? If so, I've never heard of or seen one before!

Toby

Richard T

Established Member

TobyC

Established Member

I can rest easier now. (hammer)

You really did a nice job smoothing that handle. =D>

I'm gonna go crawl back in my hole. :|

Toby

You really did a nice job smoothing that handle. =D>

I'm gonna go crawl back in my hole. :|

Toby