Rhyolith

Established Member

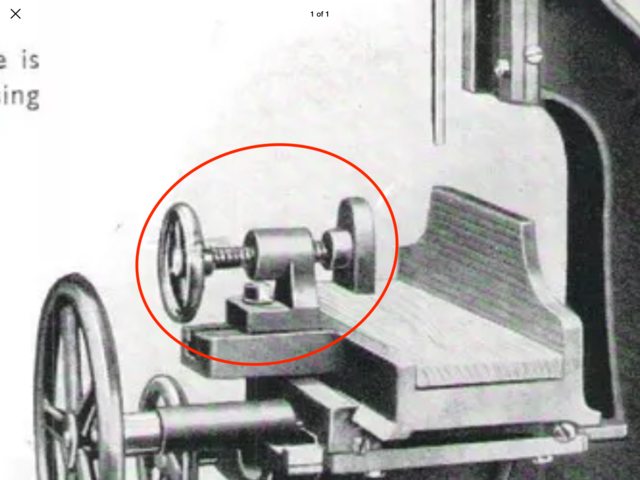

I found this amongst piles of junk on a yard on the railway. After talking with the boss i was able to bring it over to BL for restoration

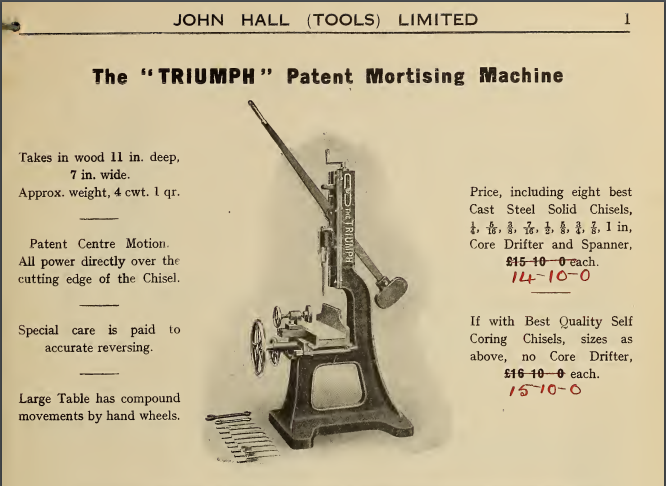

I think was made by Wilson Brothers of Leeds, possibly dating from the 1940s?

First thing first, stripping it down. Removed all the parts.

Started cleaning all of the parts 1 by 1, this was mostly done with a power brush on an angle grinder due to the extend of the rust; for smaller parts I used the wire wheel on the pedestal grinder.

Some parts needed more, such as the handle which I wanted to be shiny. This required a lot of sanding to get past all the pitting.

The iron wheel used to move the table side to side i also wanted to shine up, but this was easier

Decided to polish up the letters on the stand, not sure if this original (probably not) but I think it will look good. Probably should have used the belt sander from the start and angle grinder is NOT the right tool for this job :roll: still came out well though.

With all the parts cleaned I started painting them up with correles, which i used on the boilers for the engines... so pretty solid stuff! It smoothed out the severe pitting quite well.

I think it was originally was black (though could have been anything frankly) and thought it would look good black, so thats what I went with.

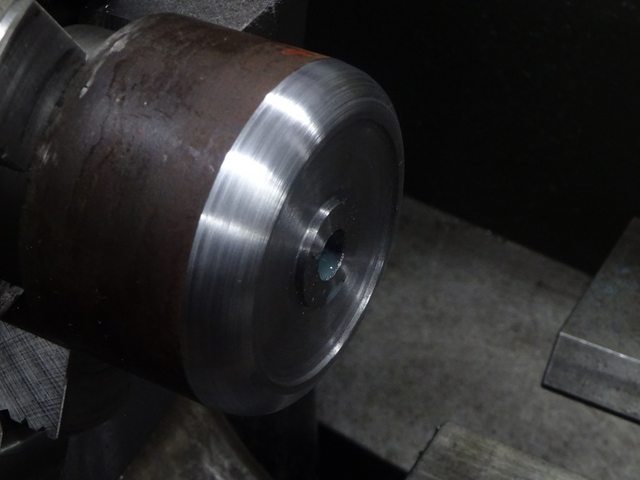

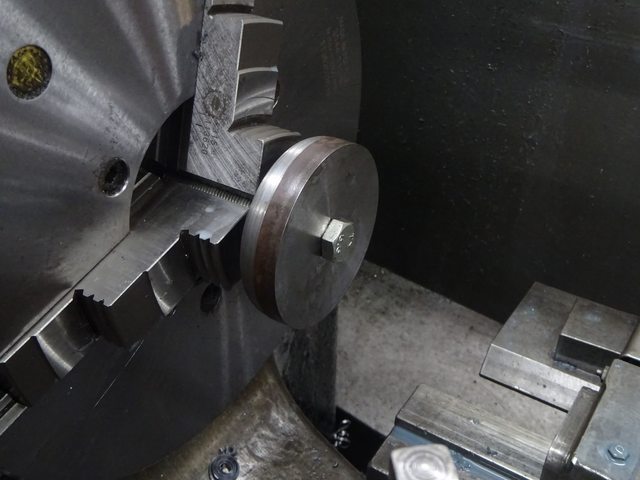

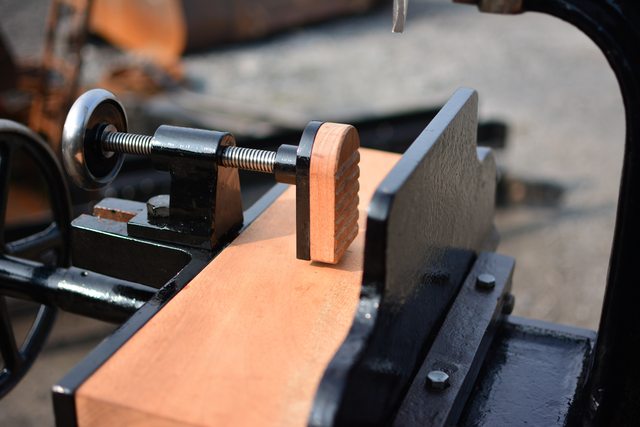

Now To the more far gone parts of which there are a few. First was the chisel holder, which just looked all horrible from heavy pitting (not the nice patina kind!). I decided to machine it in the end to get rid of it.

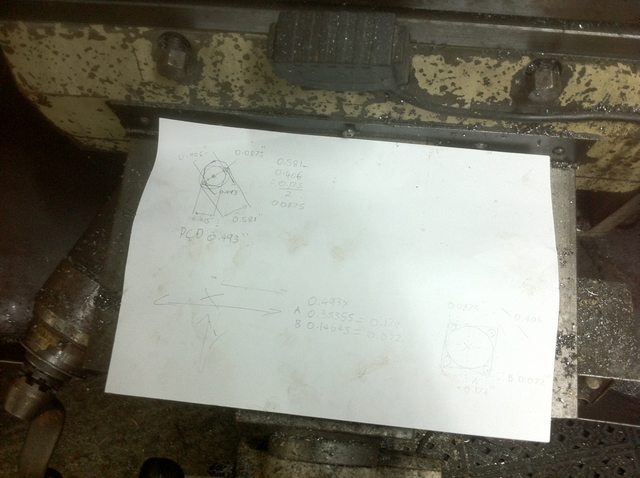

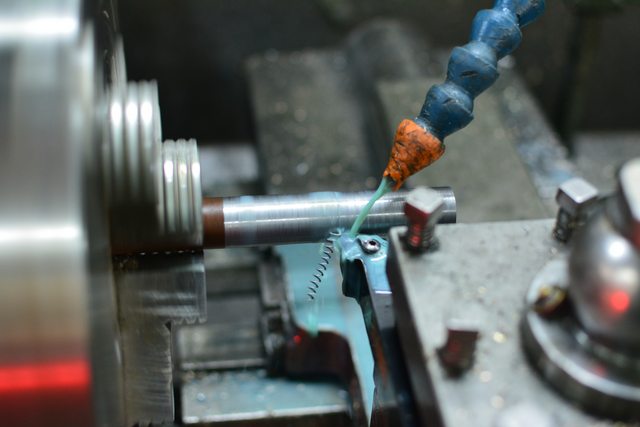

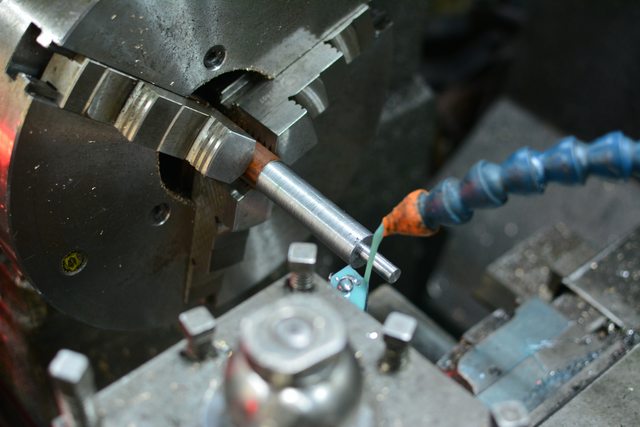

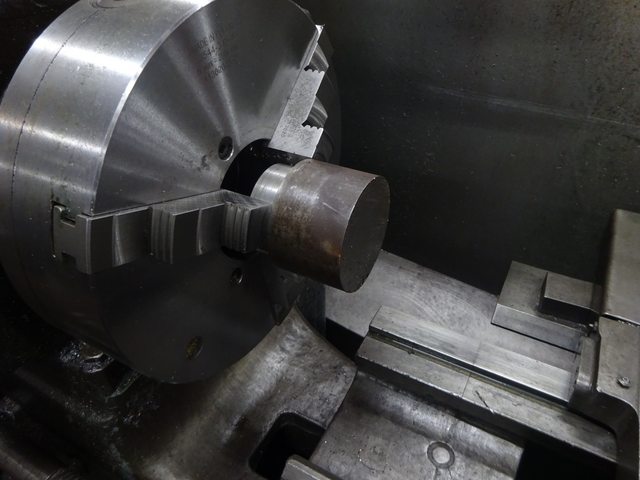

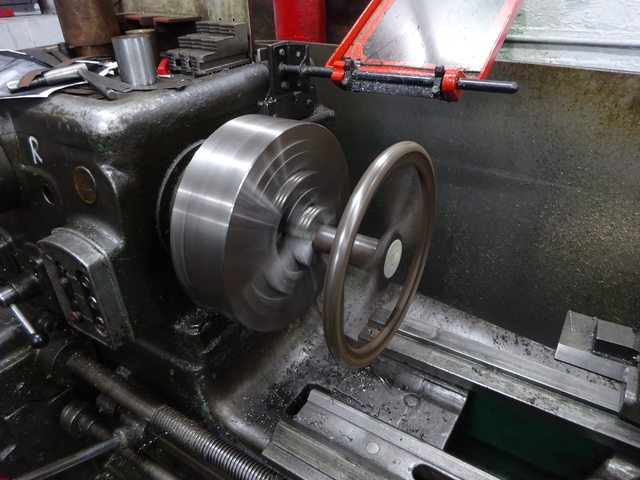

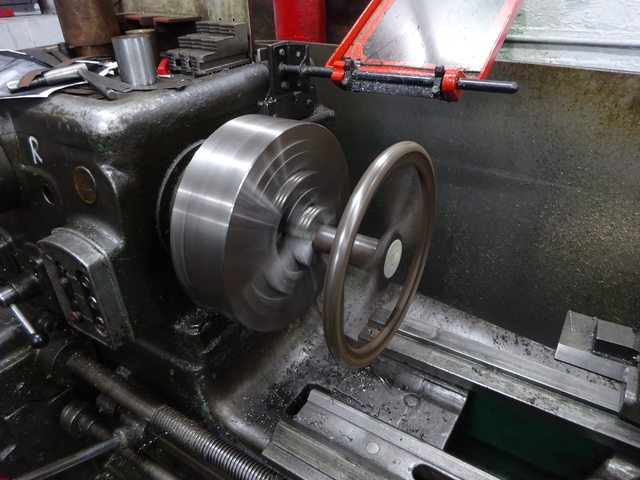

Next the thread that adjusts the chisel height was knackered, so that needed replacing! Its a 6tpi square thread (can't remember the diameter). Time to put the DSG to work

To be continued...

I think was made by Wilson Brothers of Leeds, possibly dating from the 1940s?

First thing first, stripping it down. Removed all the parts.

Started cleaning all of the parts 1 by 1, this was mostly done with a power brush on an angle grinder due to the extend of the rust; for smaller parts I used the wire wheel on the pedestal grinder.

Some parts needed more, such as the handle which I wanted to be shiny. This required a lot of sanding to get past all the pitting.

The iron wheel used to move the table side to side i also wanted to shine up, but this was easier

Decided to polish up the letters on the stand, not sure if this original (probably not) but I think it will look good. Probably should have used the belt sander from the start and angle grinder is NOT the right tool for this job :roll: still came out well though.

With all the parts cleaned I started painting them up with correles, which i used on the boilers for the engines... so pretty solid stuff! It smoothed out the severe pitting quite well.

I think it was originally was black (though could have been anything frankly) and thought it would look good black, so thats what I went with.

Now To the more far gone parts of which there are a few. First was the chisel holder, which just looked all horrible from heavy pitting (not the nice patina kind!). I decided to machine it in the end to get rid of it.

Next the thread that adjusts the chisel height was knackered, so that needed replacing! Its a 6tpi square thread (can't remember the diameter). Time to put the DSG to work

To be continued...