bugbear

Established Member

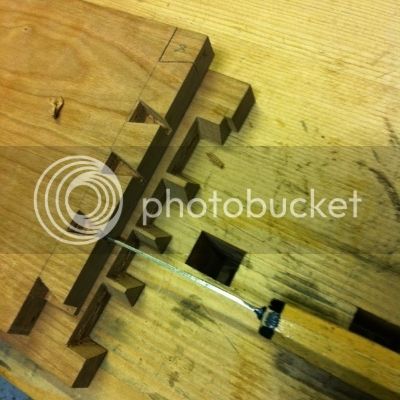

Just bought (from a dealer, for once) the narrowest chisel I've ever seen.

It's in the fairly familiar semi-mortise style, of which I have several examples, all at around the 1/8" size. They're very handy.

But the new one mike's at 0.072", or near enough 1/16". :shock:

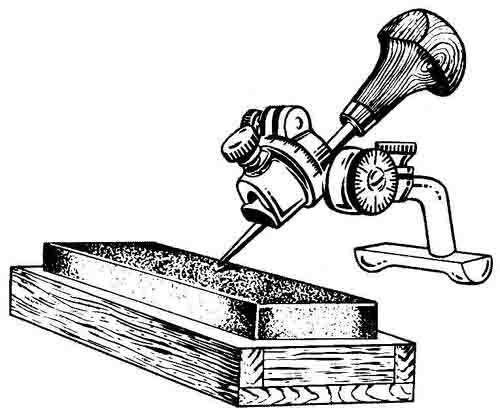

I'm planning to use a wide based jig to restore and sharpen it.

The brand is Frost of Norwich, which was a large (indeed, dominant) tool retailer. I don't therefore know who made it.

BugBear

It's in the fairly familiar semi-mortise style, of which I have several examples, all at around the 1/8" size. They're very handy.

But the new one mike's at 0.072", or near enough 1/16". :shock:

I'm planning to use a wide based jig to restore and sharpen it.

The brand is Frost of Norwich, which was a large (indeed, dominant) tool retailer. I don't therefore know who made it.

BugBear