wallace

Established Member

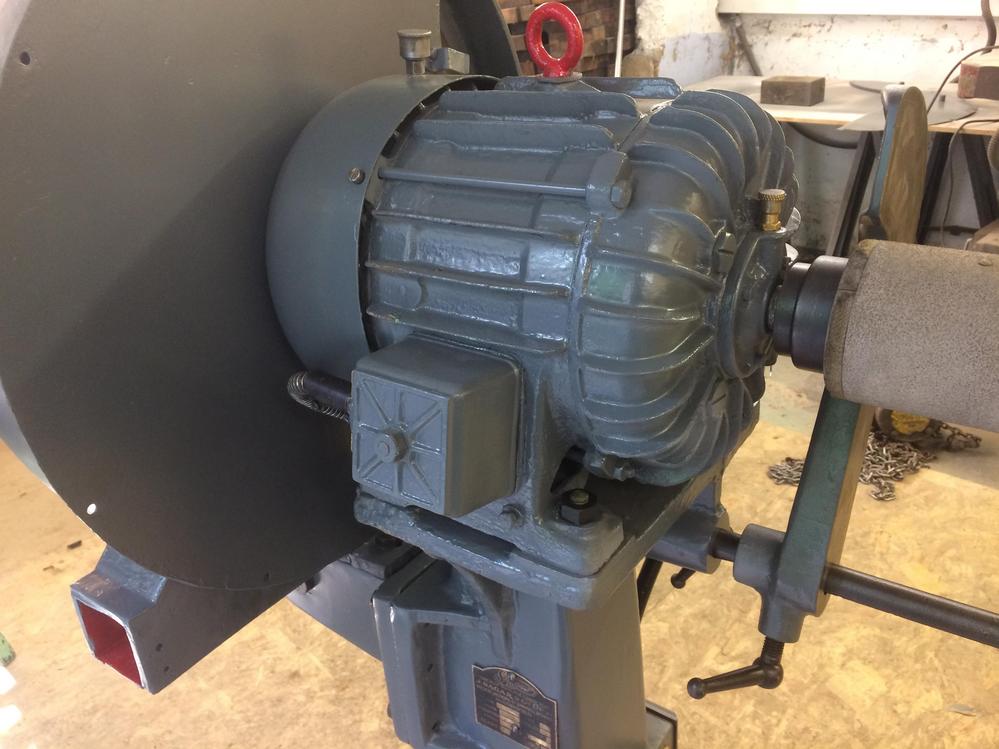

I had the good fortune to visit an old foundry to buy a couple of machines recently. This is one of them. Its quite a nice little thing with a bobbin on the backside.

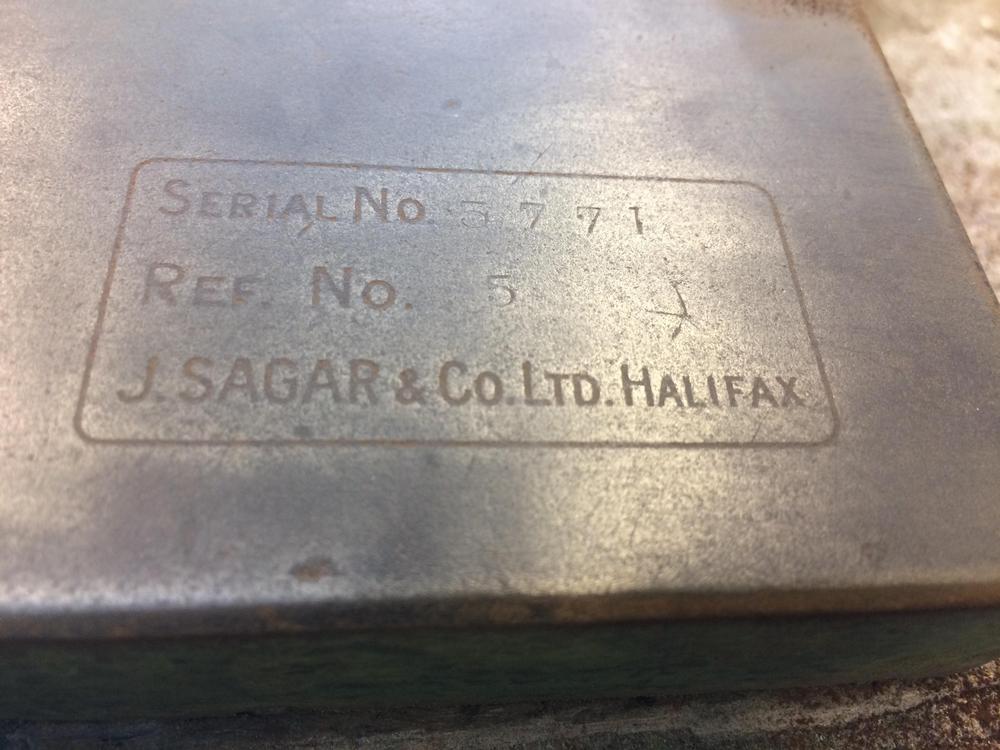

I really like these old isolators

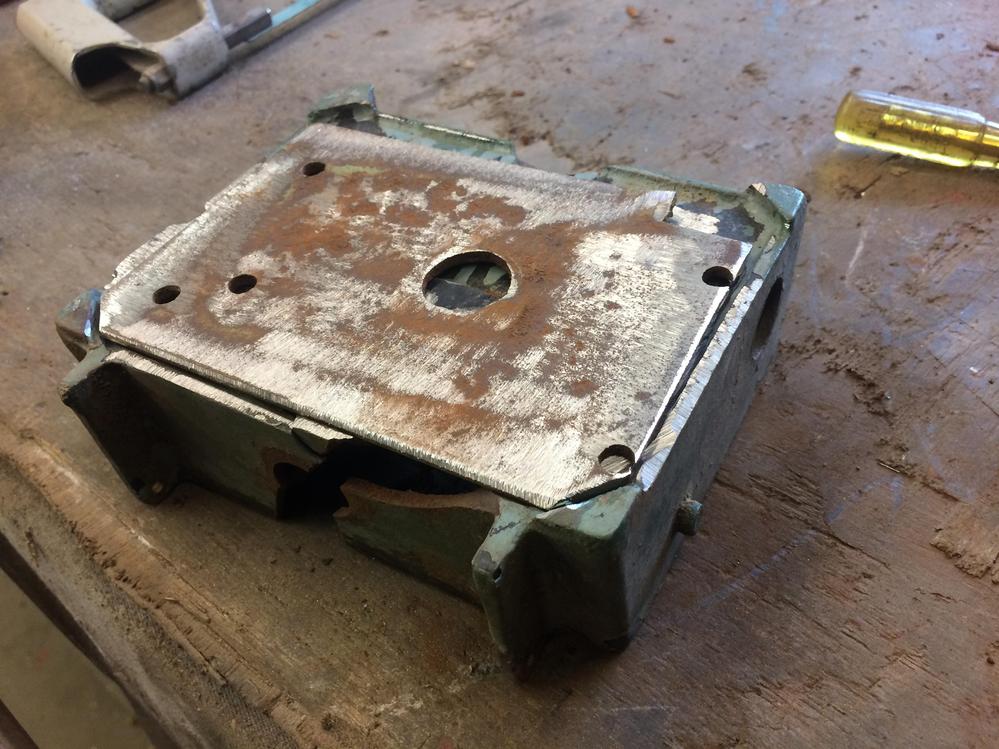

I didn't think it wise to plug it in

First balls up

The sandpaper is held in place by a ring with wing nuts on the stretch the paper over a cork insert.

Original colour very similar to wadkin

A nice brass makers tag which should look good once tarted up

A pretty neat way of holding paper for the bobbin

I don't get the four plugs in the ends bells, on one end their is brass plugs pressed in and on the other end theirs pig threaded plugs.

I really like these old isolators

I didn't think it wise to plug it in

First balls up

The sandpaper is held in place by a ring with wing nuts on the stretch the paper over a cork insert.

Original colour very similar to wadkin

A nice brass makers tag which should look good once tarted up

A pretty neat way of holding paper for the bobbin

I don't get the four plugs in the ends bells, on one end their is brass plugs pressed in and on the other end theirs pig threaded plugs.