mailee

Established Member

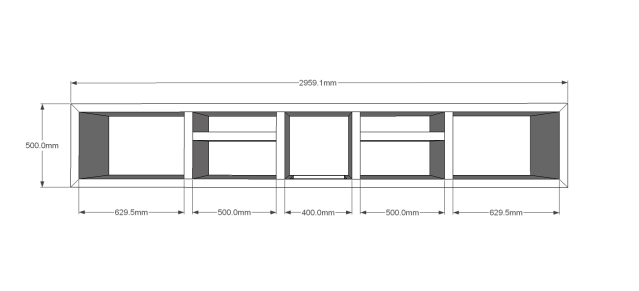

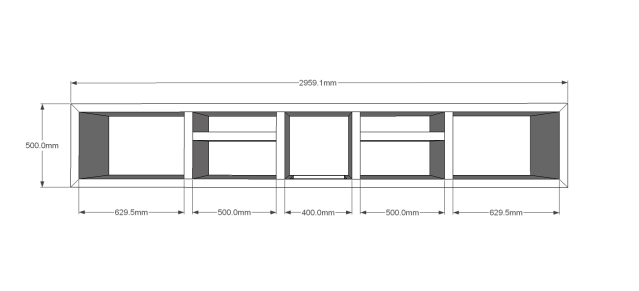

I have had an enquiry about an entertainment unit like this:

It is to be made in painted MDF and around 3M long X 450mm D X 400mm high. The customer would like it 'floating' if possible although has suggested he could have some stainless or ally legs made for it. It will be a heavy unit as he wants it 50mm thick and also wants a marble or granite plate in the centre section for an amplifier/sub woofer. Has anyone any suggestions on how to build this and if I could make it dismantle for transportation as it will weigh a ton. Access isn't a problem but it will fill one side of a room.

It is to be made in painted MDF and around 3M long X 450mm D X 400mm high. The customer would like it 'floating' if possible although has suggested he could have some stainless or ally legs made for it. It will be a heavy unit as he wants it 50mm thick and also wants a marble or granite plate in the centre section for an amplifier/sub woofer. Has anyone any suggestions on how to build this and if I could make it dismantle for transportation as it will weigh a ton. Access isn't a problem but it will fill one side of a room.