Munty Scruntfundle

Established Member

HI there.

I'm thinking of getting a small table top bench planer for sizing before blocking, glueing, turning etc.

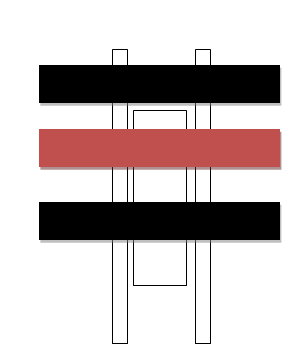

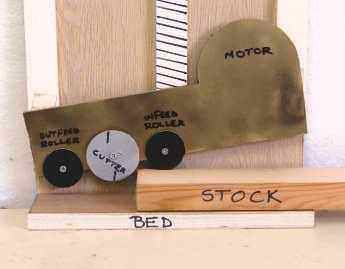

I've looked at a few reviews and I'm not really any the wiser. I don't like this thing called snipe, I'd like to use the machine with all the offcuts I can and wasting 2 or 3 inches of everything going through is going to be very wasteful. The engineer in me can't understand why this side effect hasn't been overcome.

Can anyone suggest a planer/sizer that either doesn't have this problem or minimises it? Or general recommendations for this kind of kit?

Many thanks.

I'm thinking of getting a small table top bench planer for sizing before blocking, glueing, turning etc.

I've looked at a few reviews and I'm not really any the wiser. I don't like this thing called snipe, I'd like to use the machine with all the offcuts I can and wasting 2 or 3 inches of everything going through is going to be very wasteful. The engineer in me can't understand why this side effect hasn't been overcome.

Can anyone suggest a planer/sizer that either doesn't have this problem or minimises it? Or general recommendations for this kind of kit?

Many thanks.