You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hammer K3 alloy mft / incra build

- Thread starter shed9

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

rspsteve

Established Member

Watching...... :shock:

shed9

establiSHED member

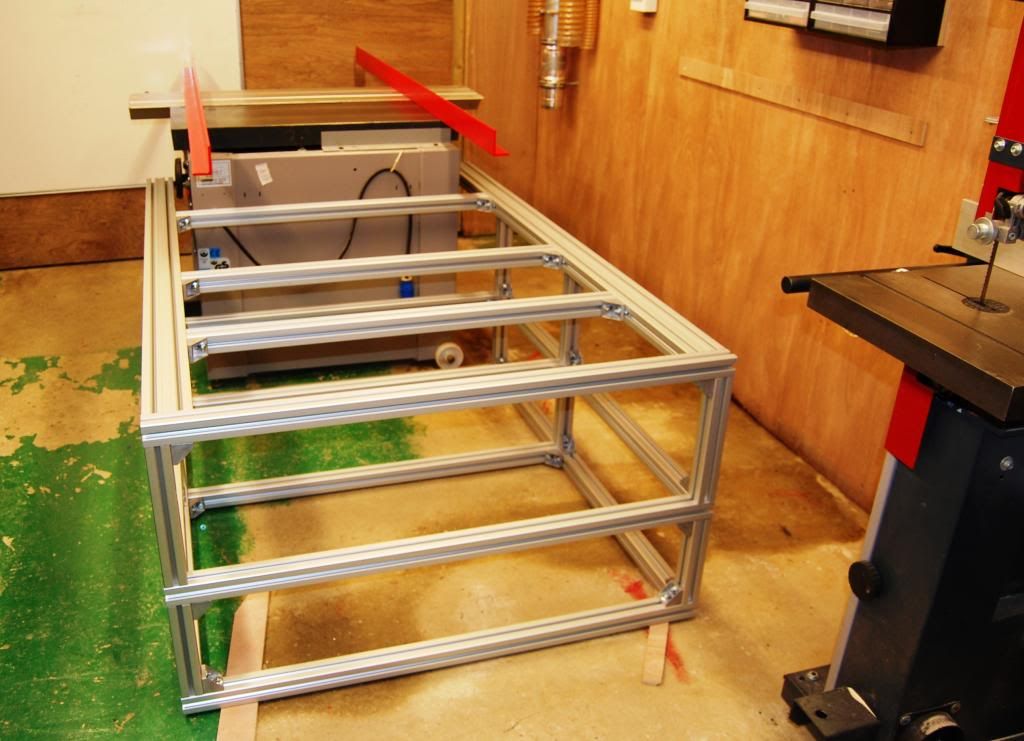

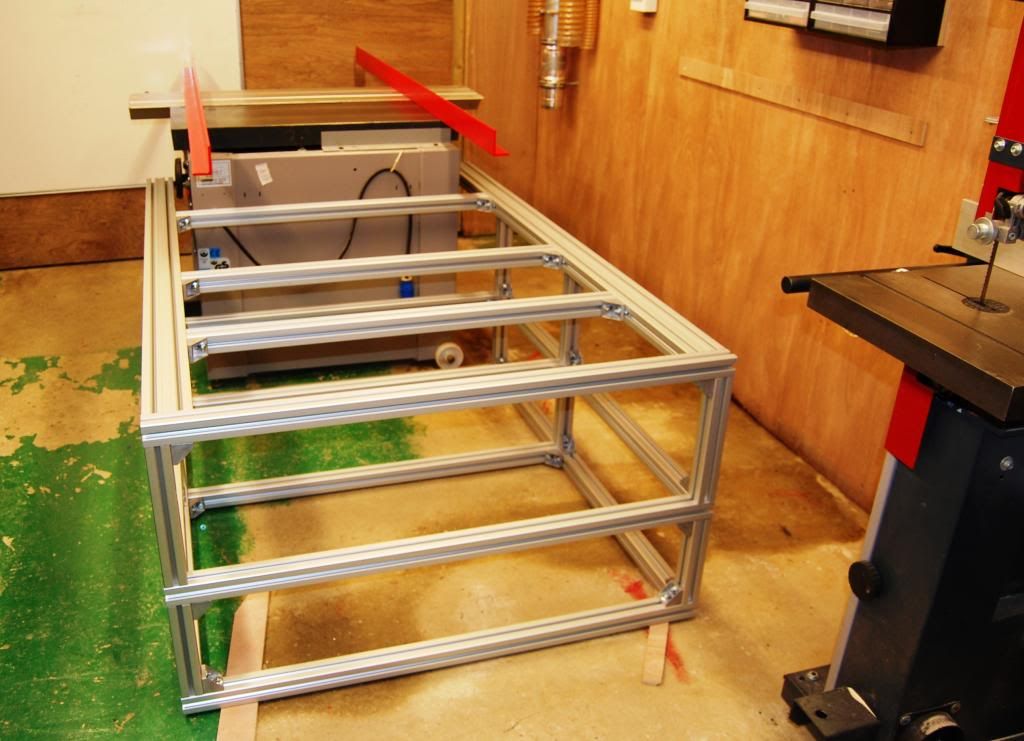

First test 'dry' build pics. Unfortunately, I discovered some damage to the long upper lengths, quick email to KJN, see what the response is.

Anyhow, the red angle iron on top will mount to the side of the table under which the upper lengths will attach with levelling feet pushing everything up. Any advice or heads up from others who are doing or have done similar modifications are most welcome.

I'm running Incra rail with an LS32 positioner and a UJK technology router lift in the middle so I can use the Incra fence for sawing and routing. I had to modify the Incra kit and fabricate an alloy base, but getting there.

Apologies for the pic-heavy start but I know some will demand them.

Anyhow, the red angle iron on top will mount to the side of the table under which the upper lengths will attach with levelling feet pushing everything up. Any advice or heads up from others who are doing or have done similar modifications are most welcome.

I'm running Incra rail with an LS32 positioner and a UJK technology router lift in the middle so I can use the Incra fence for sawing and routing. I had to modify the Incra kit and fabricate an alloy base, but getting there.

Apologies for the pic-heavy start but I know some will demand them.

shed9

establiSHED member

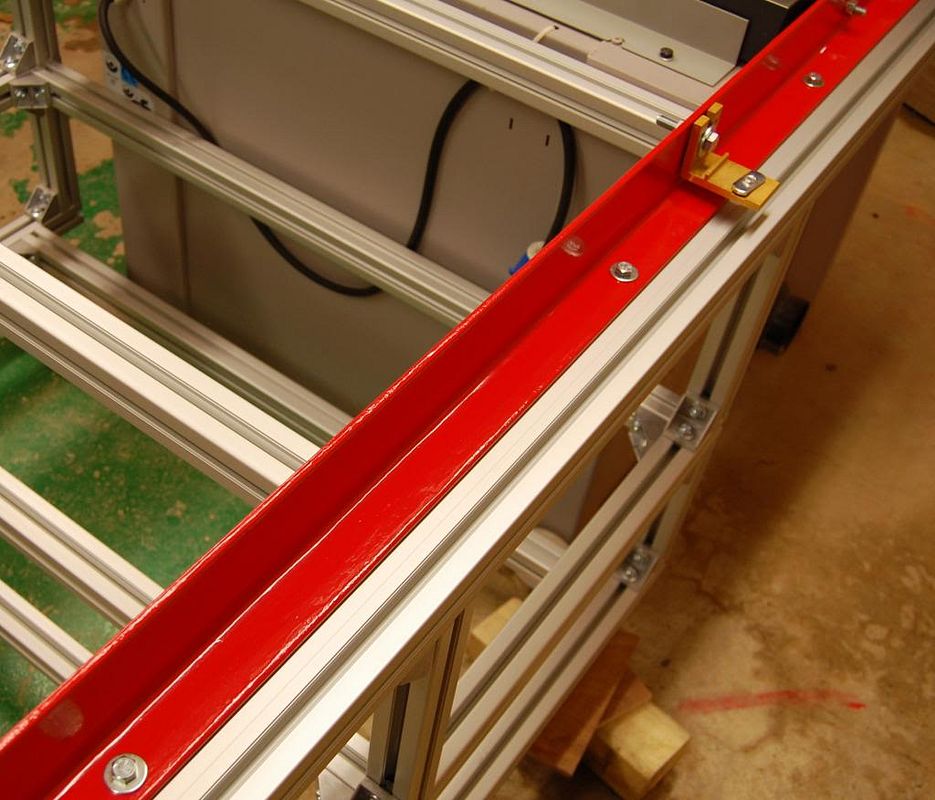

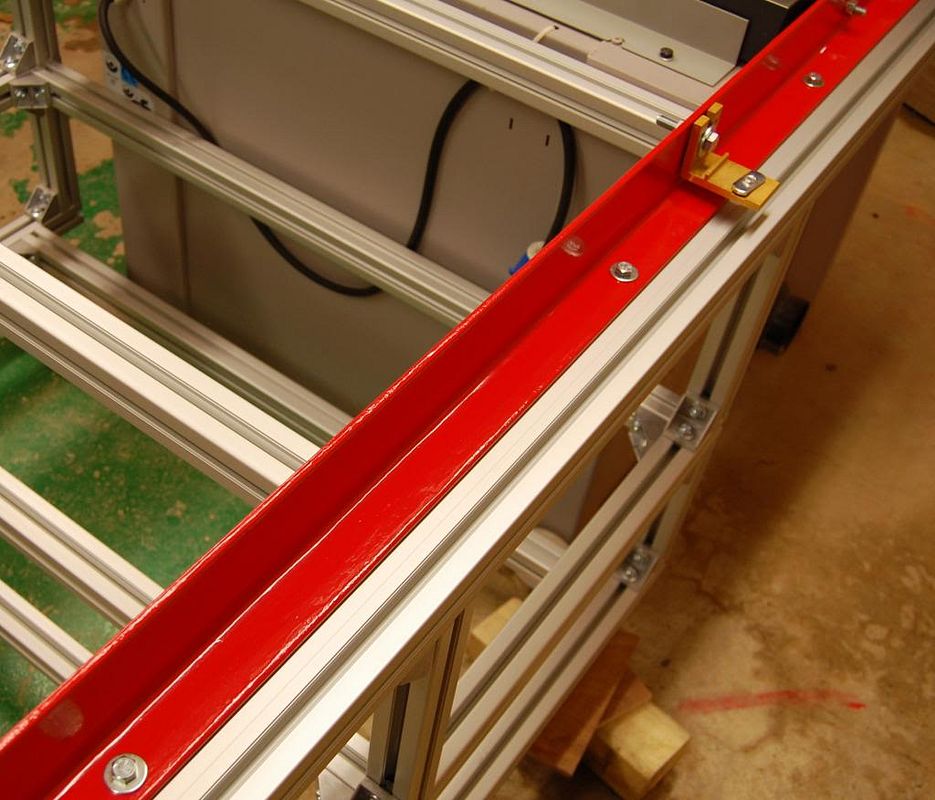

Angle iron fitted along with Incra rails, not bolted together yet, need to measure and drill the angle iron - just offered the frame up to get an idea for now;

and some idea of shelving and top level

approximate placing for router lift;

Note the ingress of water on the floor, we have had an awful lot of water in the last 24 hours as I'm sure most are experiencing.

and some idea of shelving and top level

approximate placing for router lift;

Note the ingress of water on the floor, we have had an awful lot of water in the last 24 hours as I'm sure most are experiencing.

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£238.91

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£12.50 (£1,250.00 / kg)

£14.45 (£1,445.00 / kg)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£16.59

£25.00

Woodworking Joinery by Hand: Innovative Techniques Using Japanese Saws and Jigs

Amazon.co.uk

Grahamshed

Established Member

An interesting build. I will follow this with interest.

- Joined

- 6 Jun 2011

- Messages

- 2,985

- Reaction score

- 890

Love my Hammer, sell the Incra, this is going to hold my interest. Looking forward to how its going to develop.

Peter

Peter

shed9

establiSHED member

Peter Sefton":1960ua1t said:Love my Hammer, sell the Incra, this is going to hold my interest. Looking forward to how its going to develop.

Peter

Hi Peter, I purchased an Incra Mitre 1000HD from you last year for this vey project (actually Mrs Shed9 did).

I will certainly be coming back for more bits

- Joined

- 6 Jun 2011

- Messages

- 2,985

- Reaction score

- 890

shed9":12vr3l4s said:Peter Sefton":12vr3l4s said:Love my Hammer, sell the Incra, this is going to hold my interest. Looking forward to how its going to develop.

Peter

Hi Peter, I purchased an Incra Mitre 1000HD from you last year for this vey project (actually Mrs Shed9 did).

I will certainly be coming back for more bits

Thanks for your support, we all need a Mrs Shed9 :!:

I have sent the post to Garry as you may know he's the Incra man, he doesn't get as much time as he'd like for the forum as he's busy building and developing the backend of the website, lots of new Incra being added soon

Cheers Peter

I am about to do a router table extension on my kity saw. It will have a beismeyer fence on because I have that but I am just holding fire to see how this one works out. Might use that same extrusion that you have.

shed9

establiSHED member

Peter, I look forward to the Incra expanded range. It is an odd product in that it really needs to be seen in person to appreciate its high quality.

Marcos, I got the extrusion form KJN Aluminium, its Bosch Rexroth style profile. You can get it from other places but I found they were the easiest to deal with. I can recommend them as their cutting is spot on, all of the lengths I ordered were within the exact tolerances I specified.

One thing to note, I have used the 10mm slot profile (in 45x90mm and 45x45mm), however I believe the 8mm slot profile will fit the Festool range of clamps and accessories. To be fair, my Festool clamps will slot in the 10mm however they are a tad sloppy. I ordered some 10mm slot inserts to make my own clamp adaptors. I am going to throw in a test piece of 8mm in my next order to confirm the fit for future projects - I'll update on this when I know more as it may prove useful for others. The reason I went with 10mm slot was mainly down to the size availability in that range, the nearest 8mm equivalent was 30mm and I wanted something sturdier.

I intend to drill the top surface with 20m holes on a standard Festool 96mm grid and run some specific bench dogs off the lathe - that way I can use the surface with my TS55 and the Festool range of accessories with it.

Marcos, I got the extrusion form KJN Aluminium, its Bosch Rexroth style profile. You can get it from other places but I found they were the easiest to deal with. I can recommend them as their cutting is spot on, all of the lengths I ordered were within the exact tolerances I specified.

One thing to note, I have used the 10mm slot profile (in 45x90mm and 45x45mm), however I believe the 8mm slot profile will fit the Festool range of clamps and accessories. To be fair, my Festool clamps will slot in the 10mm however they are a tad sloppy. I ordered some 10mm slot inserts to make my own clamp adaptors. I am going to throw in a test piece of 8mm in my next order to confirm the fit for future projects - I'll update on this when I know more as it may prove useful for others. The reason I went with 10mm slot was mainly down to the size availability in that range, the nearest 8mm equivalent was 30mm and I wanted something sturdier.

I intend to drill the top surface with 20m holes on a standard Festool 96mm grid and run some specific bench dogs off the lathe - that way I can use the surface with my TS55 and the Festool range of accessories with it.

- Joined

- 6 Jun 2011

- Messages

- 2,985

- Reaction score

- 890

Your right the Incra is very well made, we do have a wide range in stock with my own fully loaded router table being used and available to play with in the School workshop.

Your own table saw/router combo does look very well thought out and should be a comprehensive workstation when completed. The Ali sections also looks very good thanks for the heads up :!:

Cheers Peter

Your own table saw/router combo does look very well thought out and should be a comprehensive workstation when completed. The Ali sections also looks very good thanks for the heads up :!:

Cheers Peter

Grahamshed

Established Member

They use this aly extrusion for all sorts of stuff over the pond but hadn't found any over here. Thanks for the info.

shed9

establiSHED member

Quick update - haven't had chance to get to this recently.

Anyhow, I've machined and painted the alloy plates that will adapt the Incra positioner base to the wide aspect of the Hammer table;

These are the end plates which attach to the Incra end cheeks;

And this is the base plate that sits under the Incra main slider unit;

This is the first paint so will need flattening, but should be good to fit in a day or two.

Anyhow, I've machined and painted the alloy plates that will adapt the Incra positioner base to the wide aspect of the Hammer table;

These are the end plates which attach to the Incra end cheeks;

And this is the base plate that sits under the Incra main slider unit;

This is the first paint so will need flattening, but should be good to fit in a day or two.

shed9

establiSHED member

Another update. Had chance to finish off the base and end plates up there ^, also finished off the side rails and drilled them to fit the alloy profile;

Bit of a tenuous side line, finished off my LR32 and rail accessory holder, it's on a cleat so can move around when required - quite happy with the outcome;

Bit of a tenuous side line, finished off my LR32 and rail accessory holder, it's on a cleat so can move around when required - quite happy with the outcome;

- Joined

- 6 Jun 2011

- Messages

- 2,985

- Reaction score

- 890

All looking very neat and professorial.

Peter

Peter

shed9

establiSHED member

Thanks Peter.

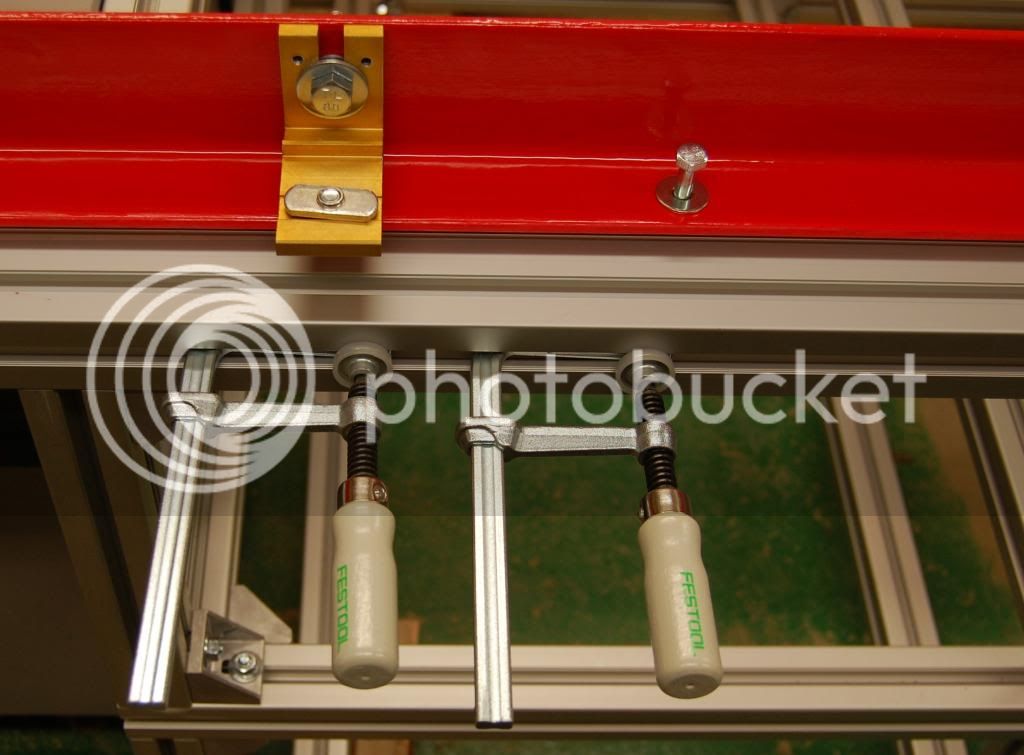

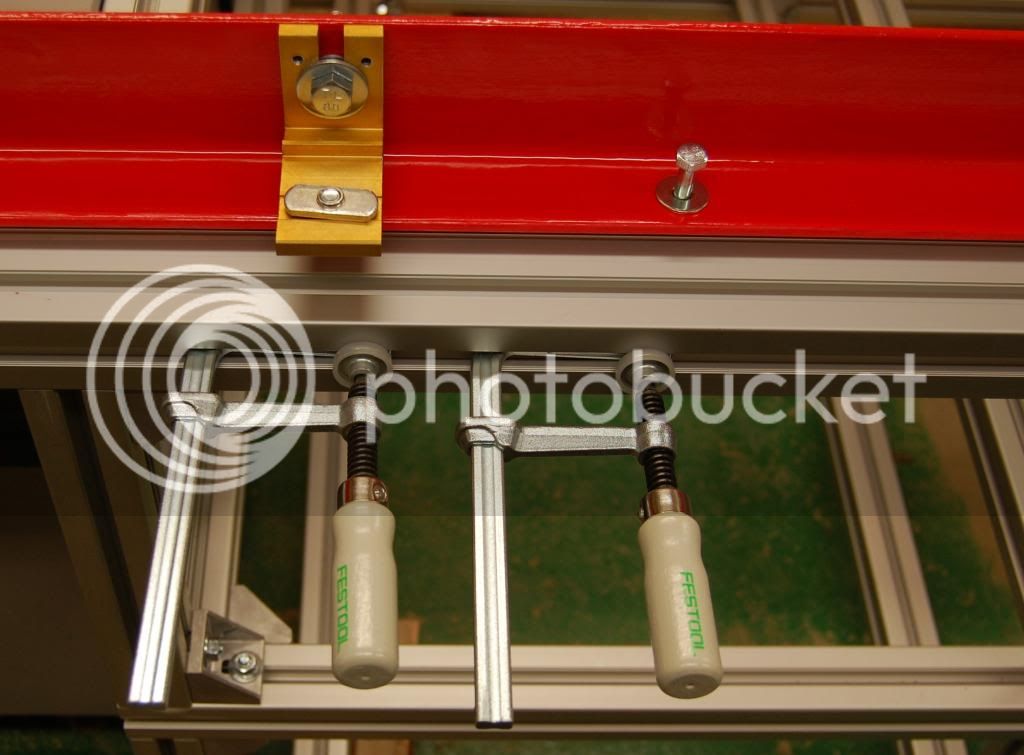

Forgot to show this as well, I mentioned earlier in the thread that Festool clamps slide right in there (albeit with a little side play) - 8mm should be better, I'll post pics when my 8mm turns up and if the clamps fit;

To be honest, there a little more slop in the clamps than I want so I'll be machining up some adaptors - more to come.

Forgot to show this as well, I mentioned earlier in the thread that Festool clamps slide right in there (albeit with a little side play) - 8mm should be better, I'll post pics when my 8mm turns up and if the clamps fit;

To be honest, there a little more slop in the clamps than I want so I'll be machining up some adaptors - more to come.

shed9

establiSHED member

Hello shed9

What set you on the path to this build, when I have been looking around most of the kit seems to be in America. May be the the UK market is smaller than I had thought. I wish I had the space to have a combo set up but I will just have to think things through to make the best of the long thin space that I have. I will be very interested to get some feed back on the ujk lifter. I seen the utube clip which looked very good and have seen two other posts one saying the sawdust was clogging up the lifters and another saying that he had a none lift plate that was bent.

Cheers tbone.

What set you on the path to this build, when I have been looking around most of the kit seems to be in America. May be the the UK market is smaller than I had thought. I wish I had the space to have a combo set up but I will just have to think things through to make the best of the long thin space that I have. I will be very interested to get some feed back on the ujk lifter. I seen the utube clip which looked very good and have seen two other posts one saying the sawdust was clogging up the lifters and another saying that he had a none lift plate that was bent.

Cheers tbone.

Similar threads

- Replies

- 6

- Views

- 947

- Replies

- 3

- Views

- 1K

- Replies

- 12

- Views

- 4K

- Replies

- 0

- Views

- 429