many of us own or have used one of the venerable quick release vices manufactured by Record and others, but I wonder how many people are familiar with the history? I certainly wasn't so I did some digging, and it appears we have a lot to thank a chap called Joseph Parkinson for. Dare I say it, it seems JP did for vices what Leonard Bailey did for bench planes, by coming up with a design that has become a defacto standard that has dominated the market for well over a century.

David Fell's father worked at the company founded by J P and has created a web site that provides some great background on the business (J Parkinson and Son, Shipley, Yorks) and about the man himself, who was clearly an impressive chap:

http://www.parkinsonshipley.co.uk/

The company survived into the 2nd half of the 20th century, and according to a booklet produced to celebrate the centenary of its founding (and summarized in the site above), JP invented his quick release vice in 1884, having come a cropper in his dealings with another company who had copied the the design of his 'handy' line of vices and began manufacturing the same in competition. Having had his fingers burned once he registered patents for the new invention in multiple countries during the next year or so. Here is the US patent (1886):

https://docs.google.com/viewer?url=pate ... 361445.pdf

...and a picture of the key working bits, taken from the Canadian patent (this patent shows the joiners vice, omitted from the drawings in the US application)

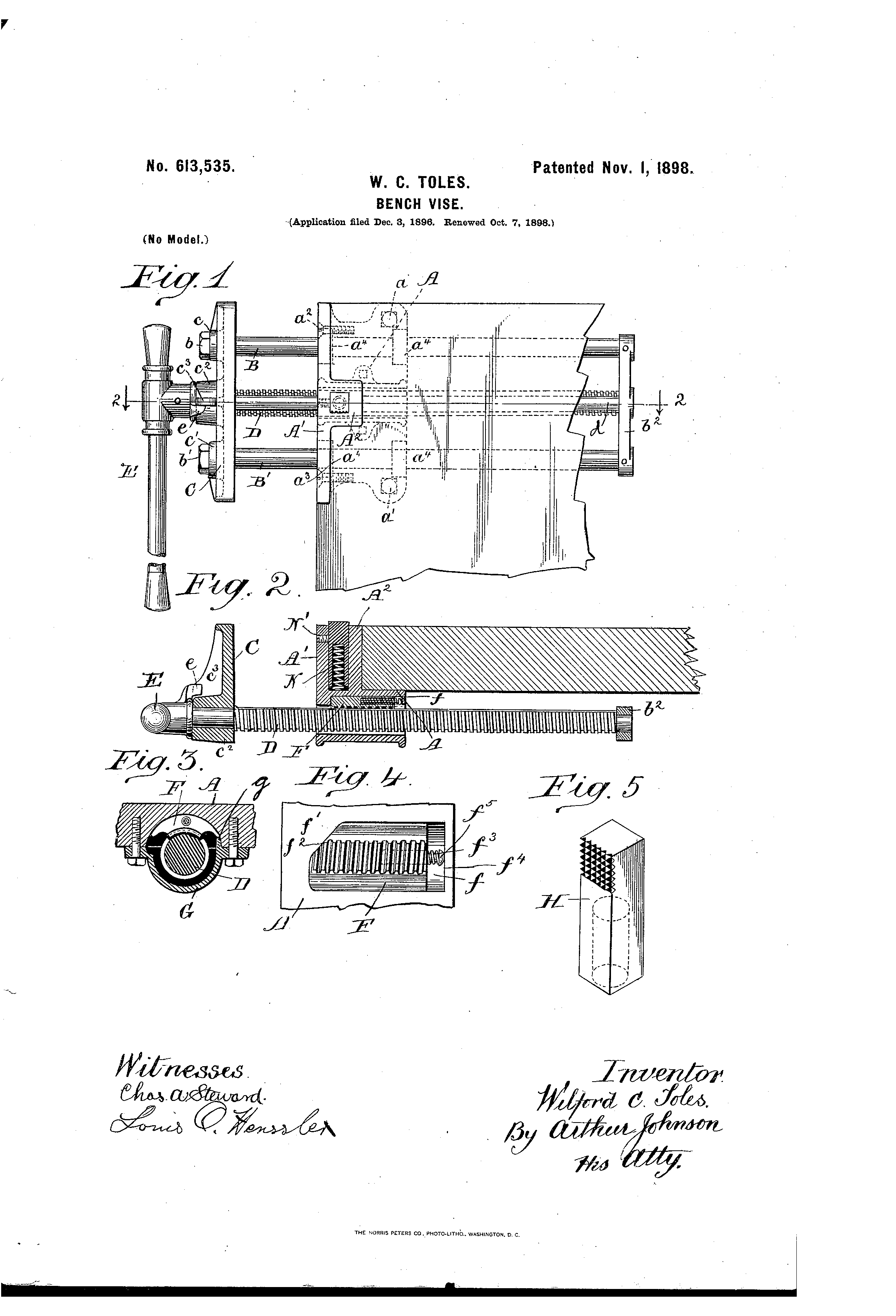

c.f Fig 6 for the joiners vice - there is a spring loaded flat bar (k) which engages with a grove in the base of a half nut (N). The bar is attached to a lever (L) next to the vice handle and when squeezed the lever causes the flat bar to pivot downwards, taking the nut with it and disengaging it from the screw. In this position the vice moves freely back and forwards.

Unfortunately the text of the Canadian patent is hand written and not very well scanned which makes it almost illegible, so we have to go just on the drawing for details, and this seems to show (fig 6) the spring that holds the bar/nut in the engaged position for the joiners vice is directly under the half nut, rather than next to the trigger (which is the familiar arrangement today).

Certainly Parkinson eventually implemented the flat spring used in more recent vises, but I suspect, but do not know for sure, that his original implementation was per the patent. Both approaches were implemented by Record, and here is an early example from them where the flat spring on the face of the vise is missing, but another spring is just visible under the nut shown below:

Parky with flat spring:

Can anyone share any more information on these details?

Although not mentioned in the patent above, it is possible JP was also the first to use a buttress thread for the screw. These threads apply a strong force in one direction, at the expense of the effectiveness of the reverse direction (not a problem when the vice can be opened without the screw using the 'instantaneous grip'). C.f toothpaste screw tops for an example of this type of thread:

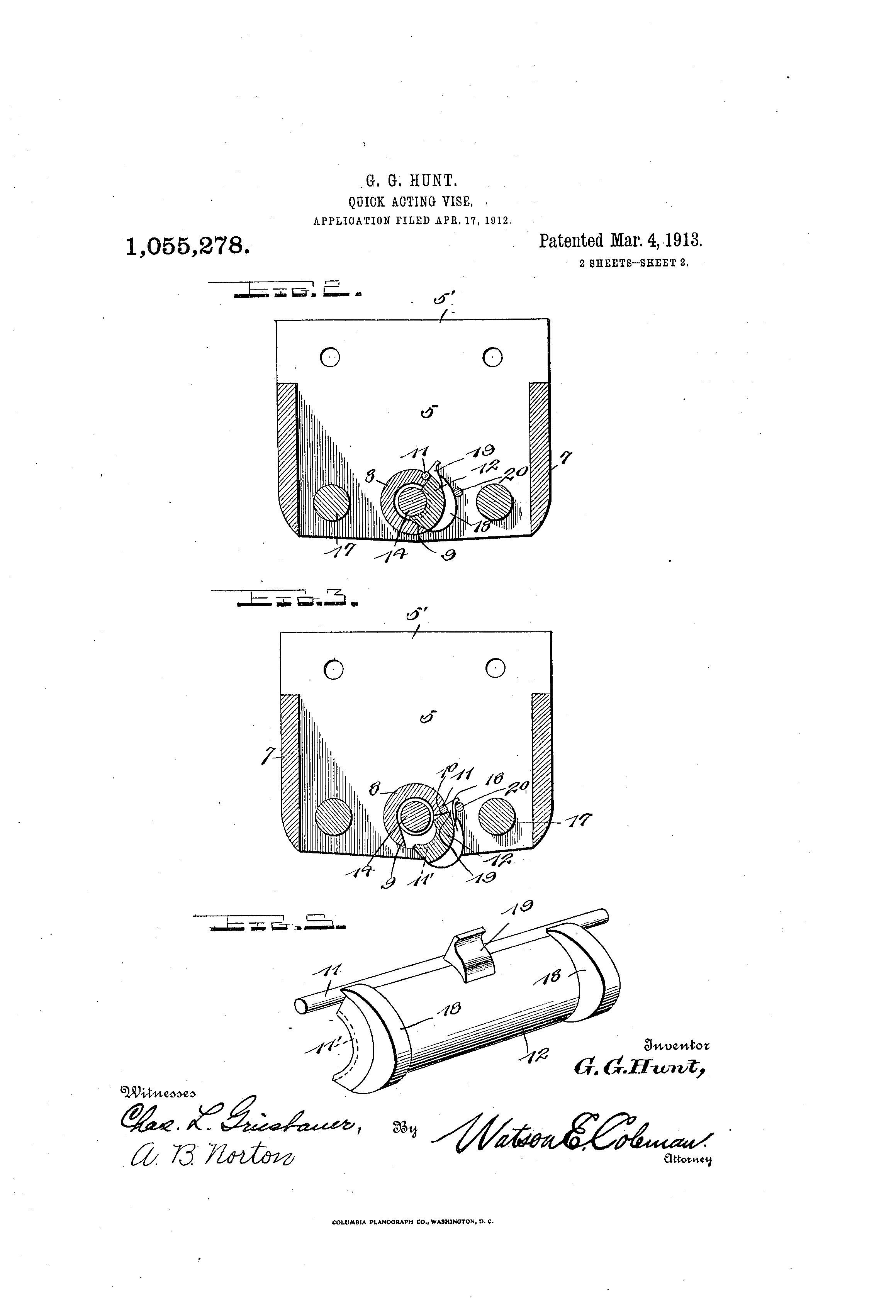

The new range of vices was called the 'patent perfect' range, and in the terminology of the day it was an 'instantaneous grip vice' - the earliest reference to the term we have settled on in recent times ( 'quick release') was about 15 years later, in a patent filed by an American. Quite probably the choice of terms reveals some deep underlying differences in our cultural identities at the time!

They were clearly very successful (and well built), since the frequently turn up for sale on ebay in working condition today. An early model is shown below (note that the vice runs on parallel cast 'sliders' rather than the round steel guides in more recent vices from Record at al (on which more in a later post). Note also unconventional (for the uk) spelling of 'vise' - no doubt to contrast with the competition (of which more in the next post).

It would also be good to hear more about the 'handy' vices that were available in the 10 years before this new design was released - was there a vice aimed at woodworkers?

Before the Joseph Parkinson design could take over the world of joinery vices, he had to overcome the competition of which there are two notable examples - The 'syers' standard instantaneous grip vice and the 'Riley' instantaneous grip vice. Find out more in the next post - gripping stuff!

David Fell's father worked at the company founded by J P and has created a web site that provides some great background on the business (J Parkinson and Son, Shipley, Yorks) and about the man himself, who was clearly an impressive chap:

http://www.parkinsonshipley.co.uk/

The company survived into the 2nd half of the 20th century, and according to a booklet produced to celebrate the centenary of its founding (and summarized in the site above), JP invented his quick release vice in 1884, having come a cropper in his dealings with another company who had copied the the design of his 'handy' line of vices and began manufacturing the same in competition. Having had his fingers burned once he registered patents for the new invention in multiple countries during the next year or so. Here is the US patent (1886):

https://docs.google.com/viewer?url=pate ... 361445.pdf

...and a picture of the key working bits, taken from the Canadian patent (this patent shows the joiners vice, omitted from the drawings in the US application)

c.f Fig 6 for the joiners vice - there is a spring loaded flat bar (k) which engages with a grove in the base of a half nut (N). The bar is attached to a lever (L) next to the vice handle and when squeezed the lever causes the flat bar to pivot downwards, taking the nut with it and disengaging it from the screw. In this position the vice moves freely back and forwards.

Unfortunately the text of the Canadian patent is hand written and not very well scanned which makes it almost illegible, so we have to go just on the drawing for details, and this seems to show (fig 6) the spring that holds the bar/nut in the engaged position for the joiners vice is directly under the half nut, rather than next to the trigger (which is the familiar arrangement today).

Certainly Parkinson eventually implemented the flat spring used in more recent vises, but I suspect, but do not know for sure, that his original implementation was per the patent. Both approaches were implemented by Record, and here is an early example from them where the flat spring on the face of the vise is missing, but another spring is just visible under the nut shown below:

Parky with flat spring:

Can anyone share any more information on these details?

Although not mentioned in the patent above, it is possible JP was also the first to use a buttress thread for the screw. These threads apply a strong force in one direction, at the expense of the effectiveness of the reverse direction (not a problem when the vice can be opened without the screw using the 'instantaneous grip'). C.f toothpaste screw tops for an example of this type of thread:

The new range of vices was called the 'patent perfect' range, and in the terminology of the day it was an 'instantaneous grip vice' - the earliest reference to the term we have settled on in recent times ( 'quick release') was about 15 years later, in a patent filed by an American. Quite probably the choice of terms reveals some deep underlying differences in our cultural identities at the time!

They were clearly very successful (and well built), since the frequently turn up for sale on ebay in working condition today. An early model is shown below (note that the vice runs on parallel cast 'sliders' rather than the round steel guides in more recent vices from Record at al (on which more in a later post). Note also unconventional (for the uk) spelling of 'vise' - no doubt to contrast with the competition (of which more in the next post).

It would also be good to hear more about the 'handy' vices that were available in the 10 years before this new design was released - was there a vice aimed at woodworkers?

Before the Joseph Parkinson design could take over the world of joinery vices, he had to overcome the competition of which there are two notable examples - The 'syers' standard instantaneous grip vice and the 'Riley' instantaneous grip vice. Find out more in the next post - gripping stuff!