Going on the basis that the TS 250 seems to be a slightly scaled-up version of the Kity 419[cough], er, TS 200:

DX on most cabinet saws is rubbish, almost by definition, as the things simply chuck too much dust around, literally. Traditionally, you used to let it fall where it would and drop down to the bottom of the cabinet, and sent the lad in there once a week with dustpan and brush. My grandfather's mill had decent-sized pits underneath the big Wadkin circular (table) saws, and cleaning (shovelling) those out was a six-monthly thing. To be fair, bigger-kerfed blades and no man-made boards meant bigger chips, so there was relatively less fine dust floating about compared to our uses.

The standard mod on the Kit[ahem] TS 200 was to remove the side of the blade guard and the nozzle, inside the cabinet and block up the big quadrant hole where the nozzle came out of the back. This reduced clogging mainly, and let the dust get away from the blade better. The trouble spot in those saws is really the belt behind the guard - keeping that side of the guard fitted keeps the worst of the "high speed" dust away from the belt and pulleys. On the Kity/TS 200, the mounting pillars for the guard also keep the riving knife mounting aligned with the tilt + rise and fall carriage of the saw. So you wouldn't want to remove it completely in any case, as the riving knife would flop around.

I'd hope this arrangement has been improved on the TS 250, as it was rather poor design (there's also a thin steel strap on the older TS 200s, which keeps the knife reasonably upright, and that strap bends very easily).

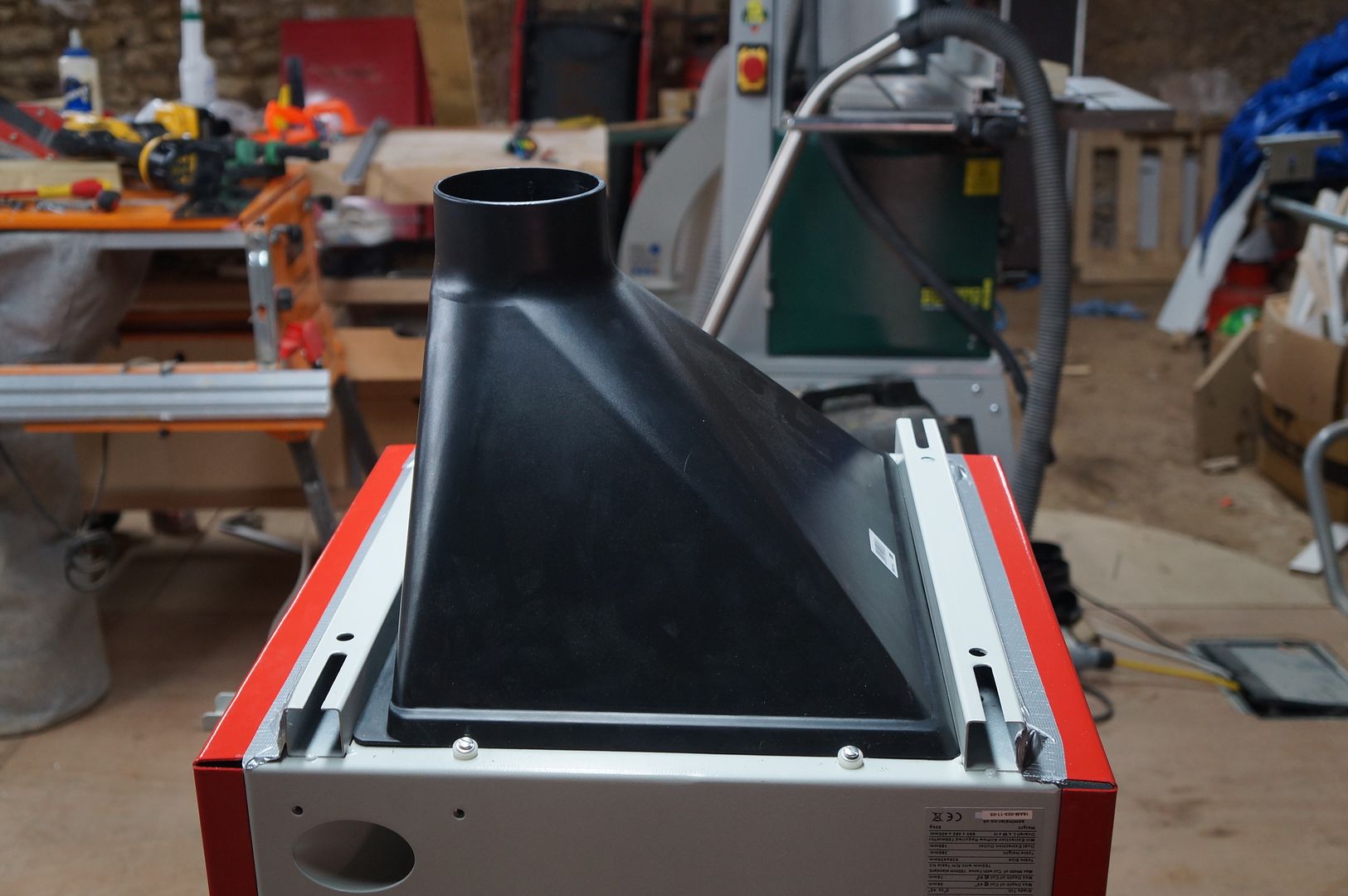

Honestly, I think you are doing the best that can be done by putting a big hopper on the bottom. If you take off the side of the guard inside (involves cutting through tack welds, probably, so is not easily reversible), that might also improve the amount of chips & dust that goes all the way round on the blade, back up topside. That's the stuff that the crown guard hose catches (theoretically!).

But I note that even very big panel saws have crown guard extraction, so clearly nobody has a perfect answer.

If you then make it easy to remove a side panel for regular cleaning (or get used to having to tip the thing over), and use something like teflon spray on the leadscrews inside so that less sawdust sticks to them, you'll probably have fettled it to be as good as it gets. Of course you'll be resigned to doing a proper hoover-out occasionally, depending on how much you use it and what you cut with it. Man made boards will be far worse than natural timber, and MDF worst of all.

The chute and 4" attachment shown above probably work best. It's what I have too (on a TS 200).

The last owner of my old Kity had also tried to block up the gaps under the table, where it sits on the cabinet frame. I wouldn't do that, personally, and I removed the gaffer tape applied. I don't think a howling gale through the blade plate is a good idea, especially if using a ZCI - you need air volume moving, not just a big pressure difference.

Get a big, floppy masonry paintbrush, or one of these:

HTH, E.