gus3049

Established Member

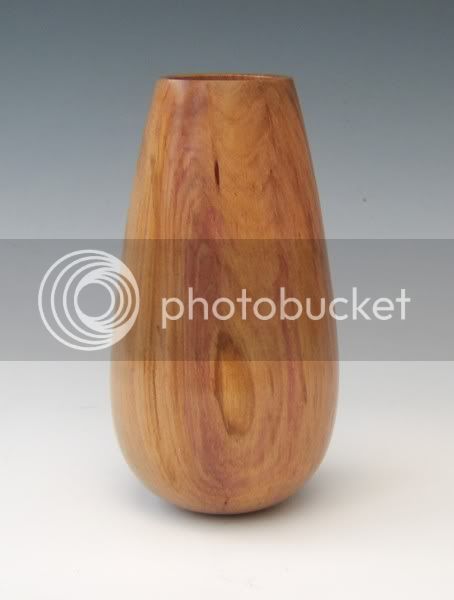

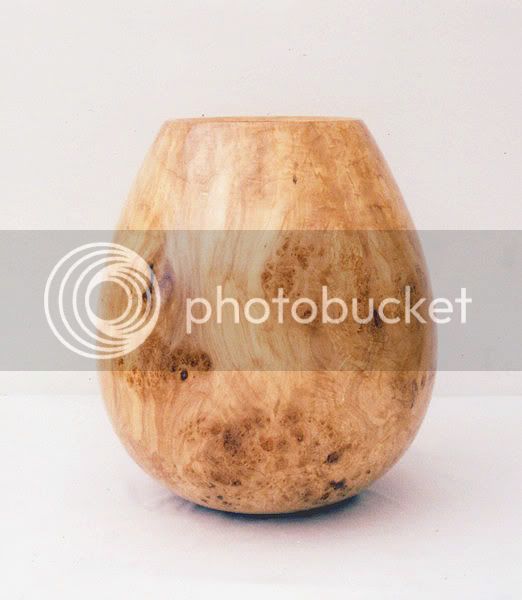

....having been inspired by the hollow forms that have been posted lately and not wanting to be a wimp, I though I'd give it a go!! We cut a Robinia (I think that's how its spelt) down about three weeks ago and there is lots of wood to experiment on. It incredibly quick growing so the rings are well spread (about 1cm apart) and should be interesting when dried out.

The only tools I have that are sort of suitable are the Hunter bowl hollowing tool and an ex-skew ground down to a metal cutting profile.

It is as hard as it looks! Trying to control the thickness of the sides when you can't see them has its interest and getting in through the small holes I have seen done boggles the mind.

These were matching! The hole on the first one got bigger and bigger as I worked! I think I made the rim too thin as there was not much heartwood left and it kept just flaking off. I have given it a quick seal to try and hold it all together whilst it dries out properly. The second went better but the hole is still about 1" across. How on earth do you do it with a smaller hole than that? And how do you finish off the inside? I've left the sides at about 3mm thick. I wish it were more even all the way down - thus the 'about'.

I don't think I will bother asking for a critique at this stage!!! But some guidance would be useful. I'm going to put them away full of their shavings for a few months whilst I ponder if all this is a good idea or am I just driving myself mad trying to master turning in six months!

The only tools I have that are sort of suitable are the Hunter bowl hollowing tool and an ex-skew ground down to a metal cutting profile.

It is as hard as it looks! Trying to control the thickness of the sides when you can't see them has its interest and getting in through the small holes I have seen done boggles the mind.

These were matching! The hole on the first one got bigger and bigger as I worked! I think I made the rim too thin as there was not much heartwood left and it kept just flaking off. I have given it a quick seal to try and hold it all together whilst it dries out properly. The second went better but the hole is still about 1" across. How on earth do you do it with a smaller hole than that? And how do you finish off the inside? I've left the sides at about 3mm thick. I wish it were more even all the way down - thus the 'about'.

I don't think I will bother asking for a critique at this stage!!! But some guidance would be useful. I'm going to put them away full of their shavings for a few months whilst I ponder if all this is a good idea or am I just driving myself mad trying to master turning in six months!