Hi all,

I know that these are supposed to go into the erm, Workshop Tour section.....but as I mostly do woodturning nowadays and it mostly concerns woodturning I thought I'd stick it in here.

Sorry if it all seems a bit self indulgent, it's not supposed to be - just thought you might be interested, there's 13 piccys - so give up now if you've a short attention span. Mostly it's a commemoration of the fact that I've done my first 'top to bottom' clean up in a couple of years - and did it need it - took me 3 days!

Looking up the shop, towards the Lathes:

The Wadkin BL150

Baby Axminster Lathe

Light Pull & assorted spindle blanks

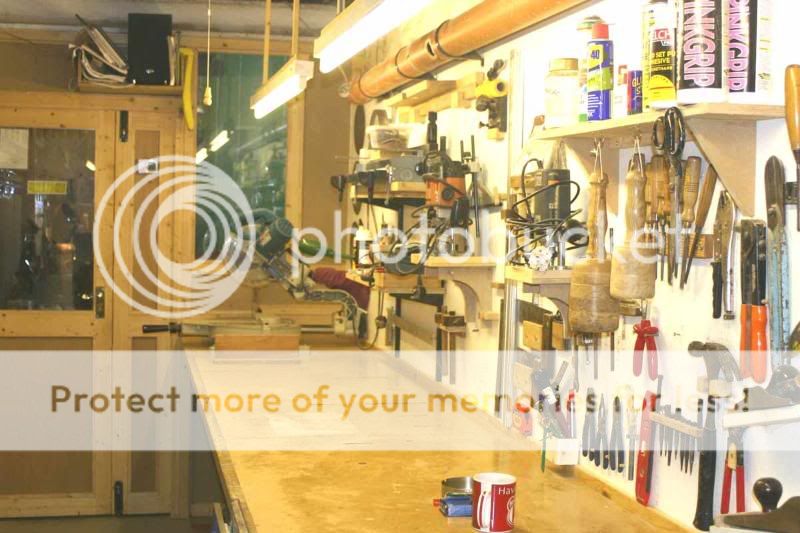

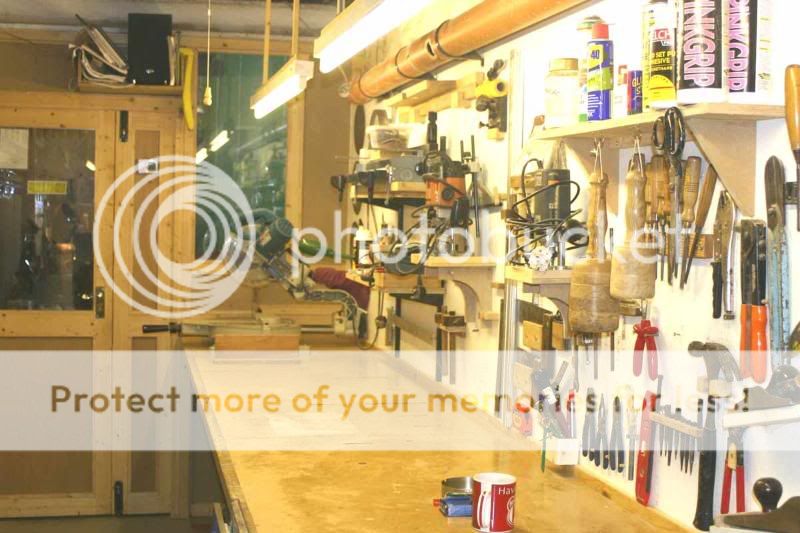

Down the shop - Left

Up the workshop - left

Up the workshop - right

Turning Blanks

The Kiln

Boards etc awaiting blanking

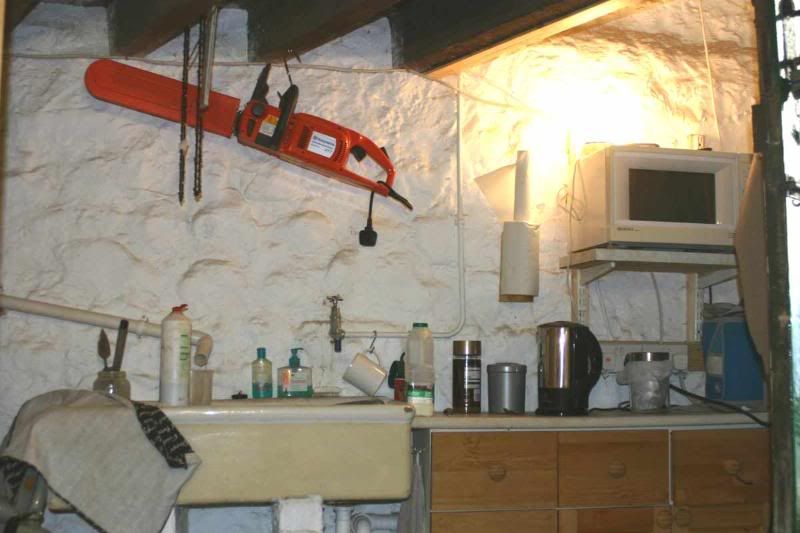

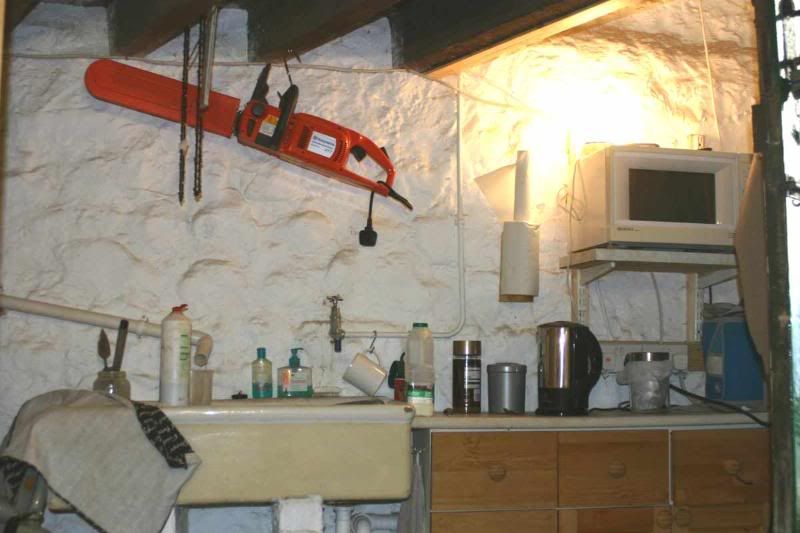

Brewtime!

Outside Woodpile

and finally.....as it was originally

I know that these are supposed to go into the erm, Workshop Tour section.....but as I mostly do woodturning nowadays and it mostly concerns woodturning I thought I'd stick it in here.

Sorry if it all seems a bit self indulgent, it's not supposed to be - just thought you might be interested, there's 13 piccys - so give up now if you've a short attention span. Mostly it's a commemoration of the fact that I've done my first 'top to bottom' clean up in a couple of years - and did it need it - took me 3 days!

Looking up the shop, towards the Lathes:

The Wadkin BL150

Baby Axminster Lathe

Light Pull & assorted spindle blanks

Down the shop - Left

Up the workshop - left

Up the workshop - right

Turning Blanks

The Kiln

Boards etc awaiting blanking

Brewtime!

Outside Woodpile

and finally.....as it was originally