Bodgers

Established Member

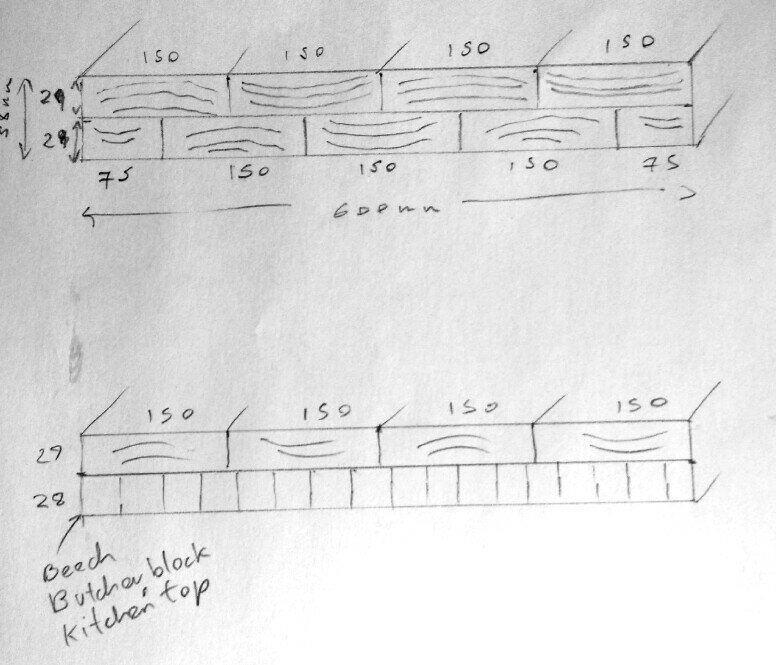

On my workbench build I'm shooting for a top thickness of approaching 60mm.

As I have mentioned previously, I have several beech slabs that vary from 32-36mm thick. After milling down I am expecting somewhere around 29mm thick boards.

I realise the standard way that this is done is the (EDIT: laminated) way with thin strips laminated with the edge (not end) grain up. But, I would like to keep things a bit simpler.

What I was thinking of doing is face gluing boards of about 150mm wide together and then laminate another layer beneath it in a brick pattern. Total width of around 600mm.

Is this too wide to glue in this direction i.e

Will it end up tearing itself apart? I would oppose the grain patterns to limit the movement.

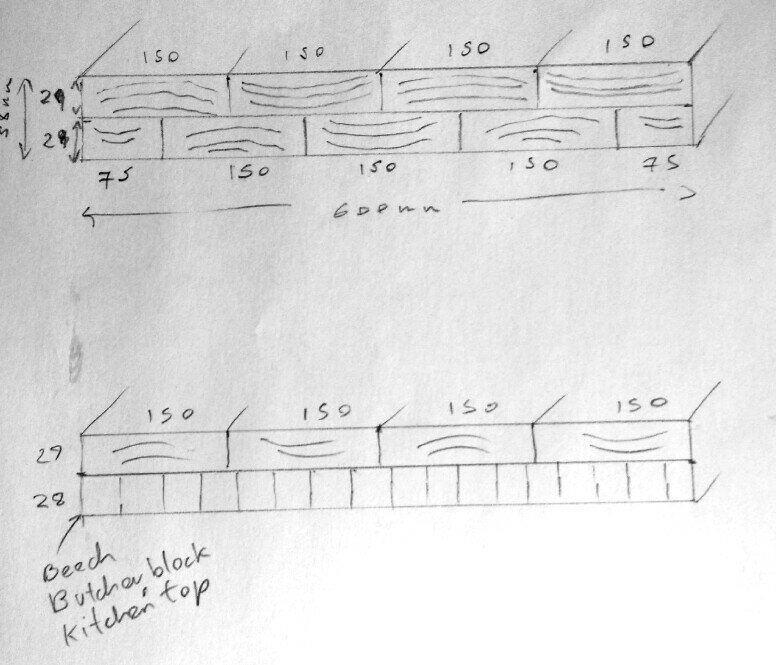

2nd option I have is that I have been offered a 28mm thick beech (EDIT: laminated stave) style counter top (new). Would it make less sense to use this in conjunction with my boards?

Sent from my MI 3W using Tapatalk

As I have mentioned previously, I have several beech slabs that vary from 32-36mm thick. After milling down I am expecting somewhere around 29mm thick boards.

I realise the standard way that this is done is the (EDIT: laminated) way with thin strips laminated with the edge (not end) grain up. But, I would like to keep things a bit simpler.

What I was thinking of doing is face gluing boards of about 150mm wide together and then laminate another layer beneath it in a brick pattern. Total width of around 600mm.

Is this too wide to glue in this direction i.e

Will it end up tearing itself apart? I would oppose the grain patterns to limit the movement.

2nd option I have is that I have been offered a 28mm thick beech (EDIT: laminated stave) style counter top (new). Would it make less sense to use this in conjunction with my boards?

Sent from my MI 3W using Tapatalk