You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Woodrat mods

- Thread starter Johnboy

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Chris Knight

Established Member

John

It sounds pretty ingenious but I look forward to seeing the photos as I can't quite work out how it will work in practice - getting dim in my old age I guess!

It sounds pretty ingenious but I look forward to seeing the photos as I can't quite work out how it will work in practice - getting dim in my old age I guess!

nickson71

Established Member

looks interesting .......

Johnboy

Established Member

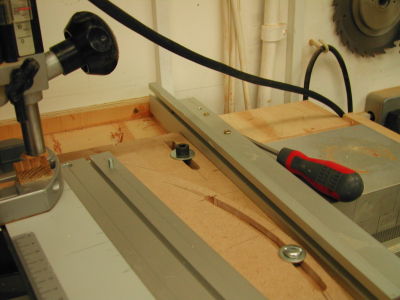

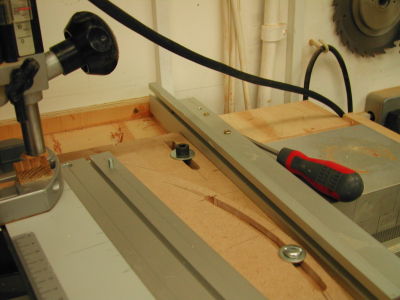

Here are the pictures of the prototype.

This is the setup for normal use, the router sildes north/south at 90 deg to the woodrat face. The 15mm MDF bottom plate reduces the max depth of cut so I will replace this with 6mm aluminium now I know it works. The 6mm MDF plate pivots on the lower plate and is locked by the screw in the curved slot at the right. The bottom plate can be adjusted to change the pivot points position in relation to the woodrat face. The ali extrusion on the right is fixed at 90deg to the woodrat face so when adjusting the bottom plate north/south it can be pushed against this to make sure everything stays square.

Here the router is swung to the right for dovetail pin cutting. The orange pegs are set for a 1:7 pin slope. When I remake it in aluminium will add better made stops for different pin slopes.

A close up of the pivot locking screw (this will be replaced with a knob that can be tightened by hand as will the cap screws for the main plate adjustment.

The router is slid forward here to show the pivot point.

Everything removed except the bottom plate to show the pivot point.

A couple of pictures of a completed joint.

I use Aldels method of cutting the tails then marking out the pins from these and then cut to the lines on the 'rat so dont really need the north south adjustment on the bottom plate.

The big advantage is that when changing from cutting the tails to the pins you just have to loosen the locking screw and then you can pivot the router to cut the pins. No removing the guide rails and no messing about with the button.

John

This is the setup for normal use, the router sildes north/south at 90 deg to the woodrat face. The 15mm MDF bottom plate reduces the max depth of cut so I will replace this with 6mm aluminium now I know it works. The 6mm MDF plate pivots on the lower plate and is locked by the screw in the curved slot at the right. The bottom plate can be adjusted to change the pivot points position in relation to the woodrat face. The ali extrusion on the right is fixed at 90deg to the woodrat face so when adjusting the bottom plate north/south it can be pushed against this to make sure everything stays square.

Here the router is swung to the right for dovetail pin cutting. The orange pegs are set for a 1:7 pin slope. When I remake it in aluminium will add better made stops for different pin slopes.

A close up of the pivot locking screw (this will be replaced with a knob that can be tightened by hand as will the cap screws for the main plate adjustment.

The router is slid forward here to show the pivot point.

Everything removed except the bottom plate to show the pivot point.

A couple of pictures of a completed joint.

I use Aldels method of cutting the tails then marking out the pins from these and then cut to the lines on the 'rat so dont really need the north south adjustment on the bottom plate.

The big advantage is that when changing from cutting the tails to the pins you just have to loosen the locking screw and then you can pivot the router to cut the pins. No removing the guide rails and no messing about with the button.

John

AndyBoyd

Established Member

Very nice indeed, now another thing for me to make, all the renovations and the list of furniture to be made may be delayed again!!!!

aldel

Established Member

Hi Johnboy,

Impressive stuff. I was a little confused by your technical drawings but the photos now make it so much clearer. I am wondering about the available depth of cut as you have three layers to pass through before reaching the work. I guess an alloy plate will improve things there.

Isn't it great when an idea actually works?!

Regards, Aldel

Impressive stuff. I was a little confused by your technical drawings but the photos now make it so much clearer. I am wondering about the available depth of cut as you have three layers to pass through before reaching the work. I guess an alloy plate will improve things there.

Isn't it great when an idea actually works?!

Regards, Aldel

£234.08

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£16.59

£25.00

Woodworking Joinery by Hand: Innovative Techniques Using Japanese Saws and Jigs

Amazon.co.uk

A

Anonymous

Guest

That is looking very nice John. I like it a lot

nickson71

Established Member

Thats very interesting ........ once you remade it with the alloy / aluminum plate could you let use know how it works out as I for one will be very interested .........

thanks

Ian

thanks

Ian