Update time.

Made the paws and feet, the health and safety guys would be horrified if they saw how I made the pads for the feet!

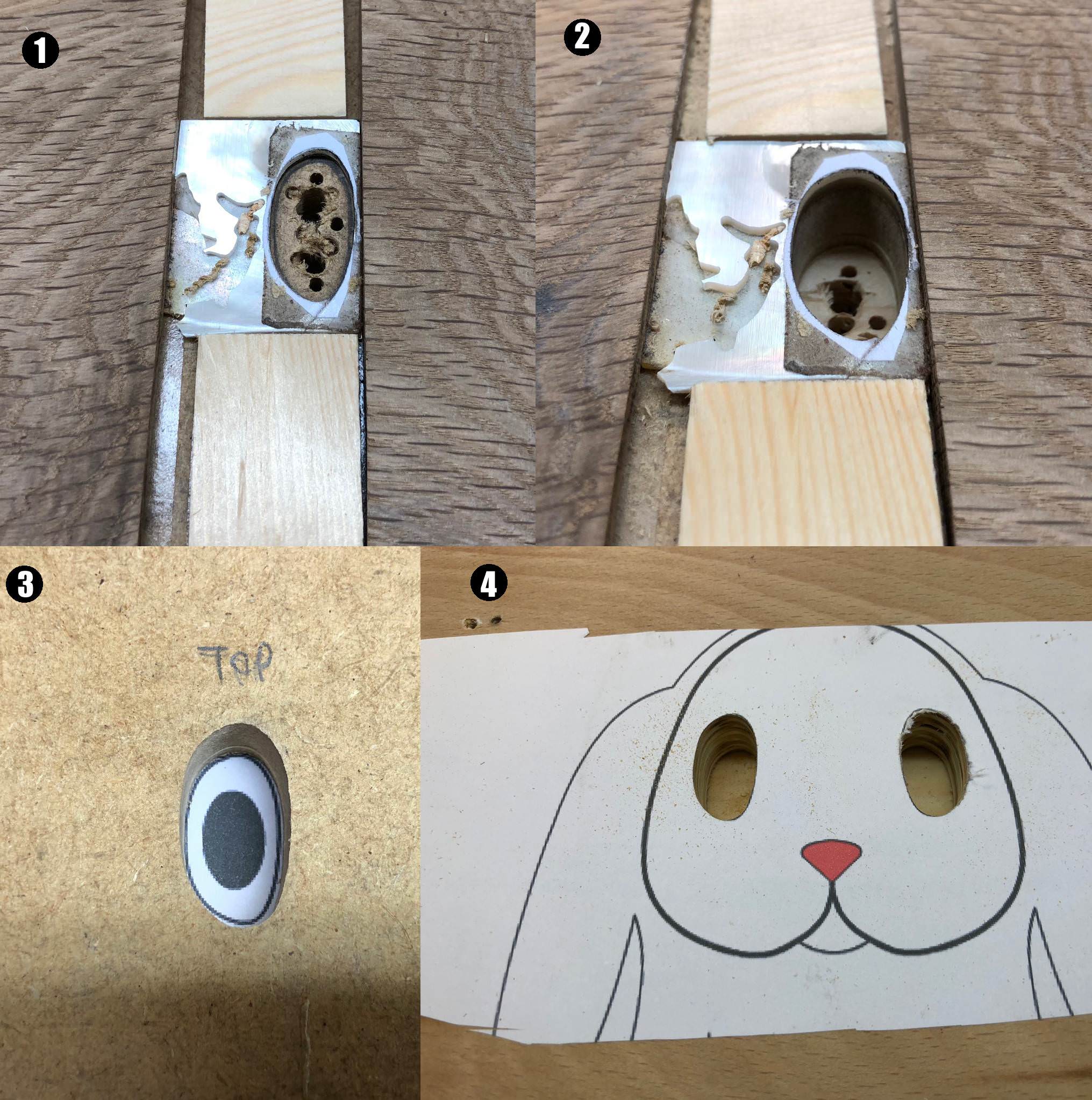

So still having my fingers I did the bit I was dreading, inlaying the eyes. I've gone into a bit of detail here in case it's of use to anyone.

Wanted to use mother of pearl for the eyes, it cuts and sands fairly easily, stuck the diagram on the M.O.P. I taped double sided taped two sheets together so I only had to make one cut and hopefully end up with 2 identical eyes. The shape cut out with a very fine blade jeweller's saw.

Then needed to make a routing template for the inlay....

1. stuck the offcut onto some MDF and reinforced edges with scraps

2. routed it out with a template routing bit, the mother of pearl just about thick enough for the bit's bearing

3. got one eye template on 12mm thick MDF

4. transferred it on to 18mm ply to make a complete pair of eyes template

I'm doing all this to try and make a jig that's *****-proof!

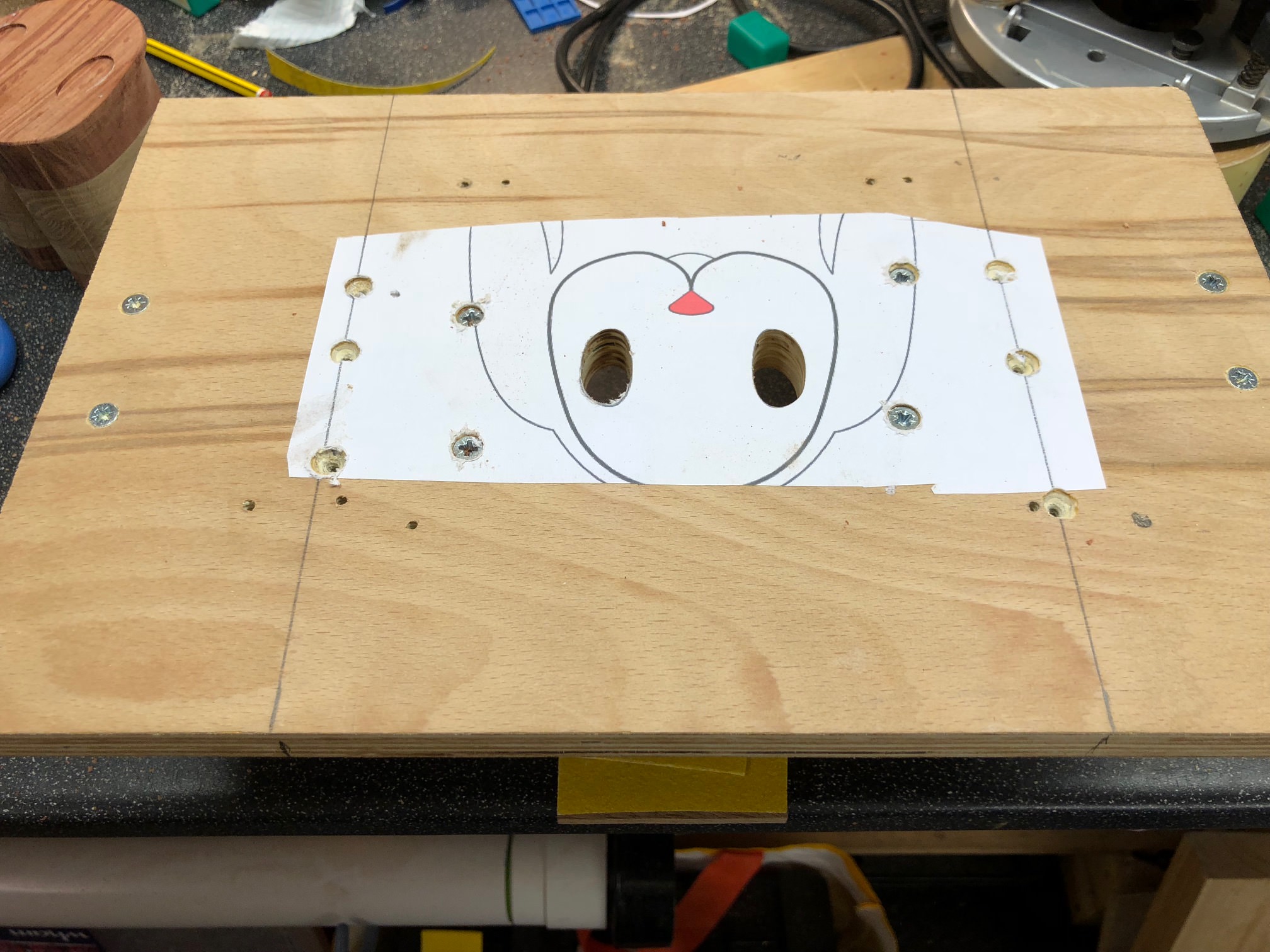

made that into a crude table

Everything clamped up one day I'll get one of those fancy DeWalt laminate trimmers but until then, time to Bosch it out! All this work just to rout out a couple of 1.2mm cavities.

Final result, not bad fit.

So with eyes installed, still need to do middle bit, gonna fill that with black paint coloured epoxy, here's the latest state of play:

round bit to the left is the tail to be glued on later.

Haven't glued on the nose or paws yet. I'm a bit concerned about the nose as it's to be the drawer pulling knob but it's a tiny, not much surface area for the glue to hold. Wondering if I should screw it from the inside of draw?