sploo

Somewhat extinguished member

I'm in the process of making a workbench to take my lathe. The idea is to build something similar in height to the official stand, with strong sides that will allow me to bolt on the extension bed (for large diameter turning).

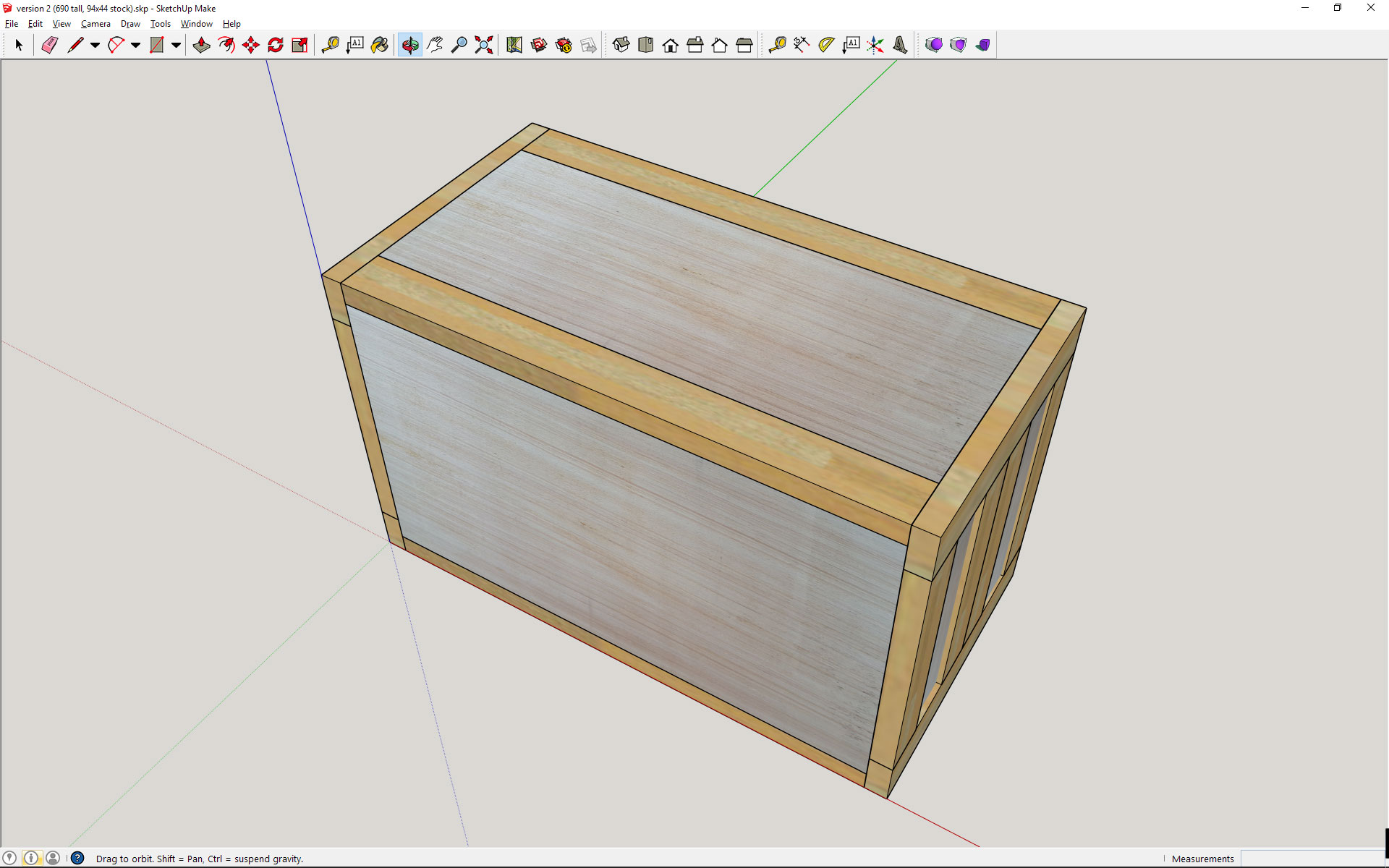

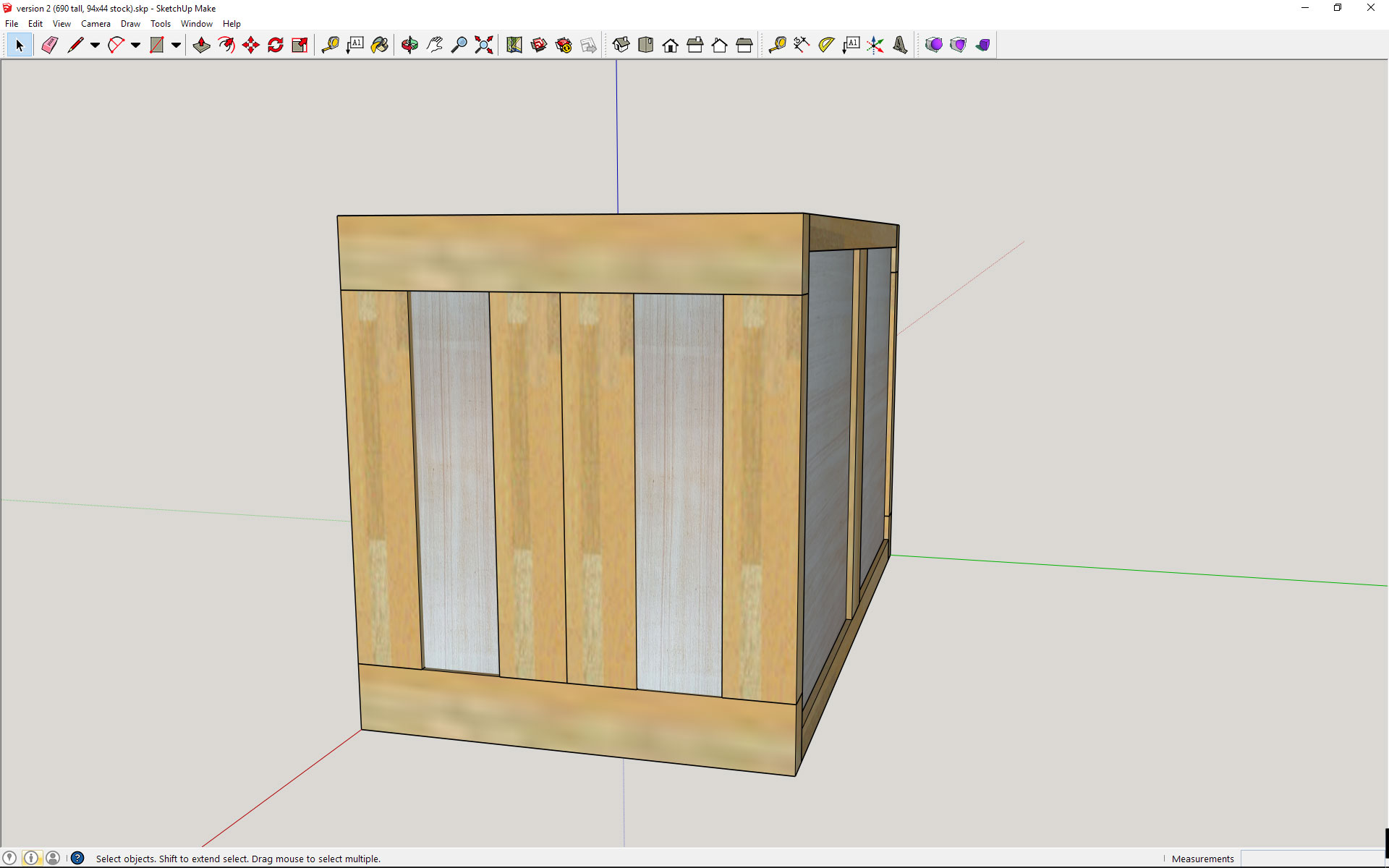

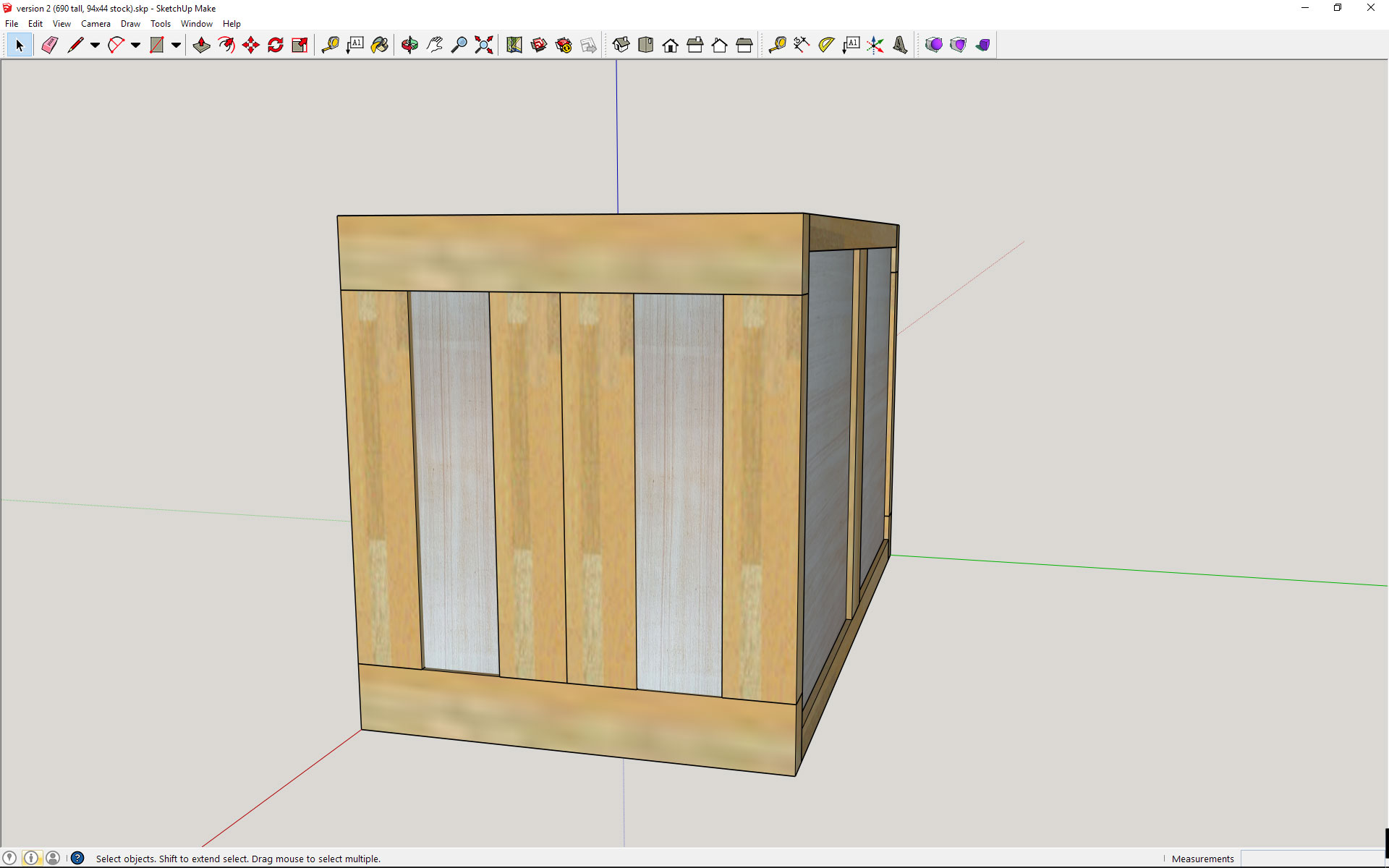

From the front it should look a bit like this (though with doors and drawers):

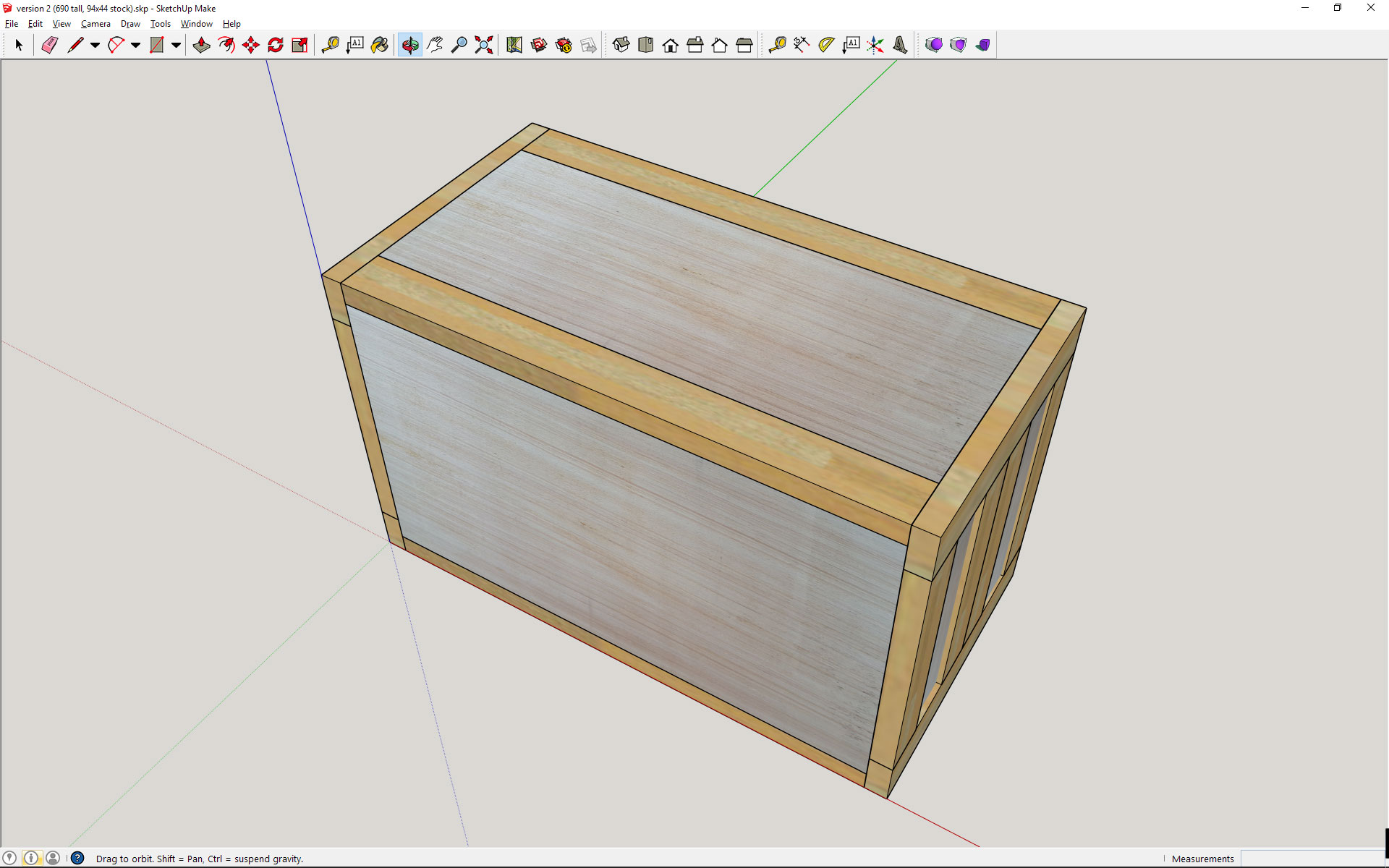

From the side/rear:

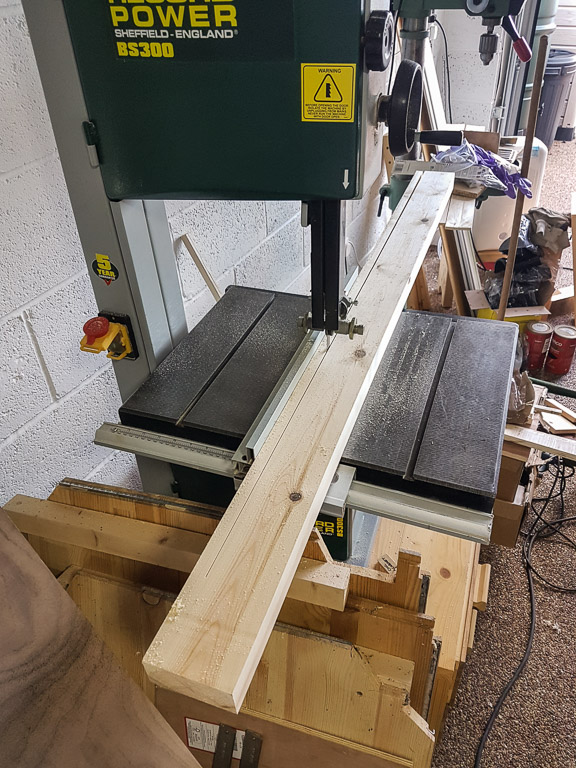

I managed to source some reasonable quality 94x44mm redwood, and despite the fact it was already planed it did need some extra work. It was well worth the effort with the planer and thicknesser, and I ended up with 92x41.5mm stock that was pretty straight and square. An initial set of cuts for the sides fit together very well (the fat centre piece is two sections of stock glued together):

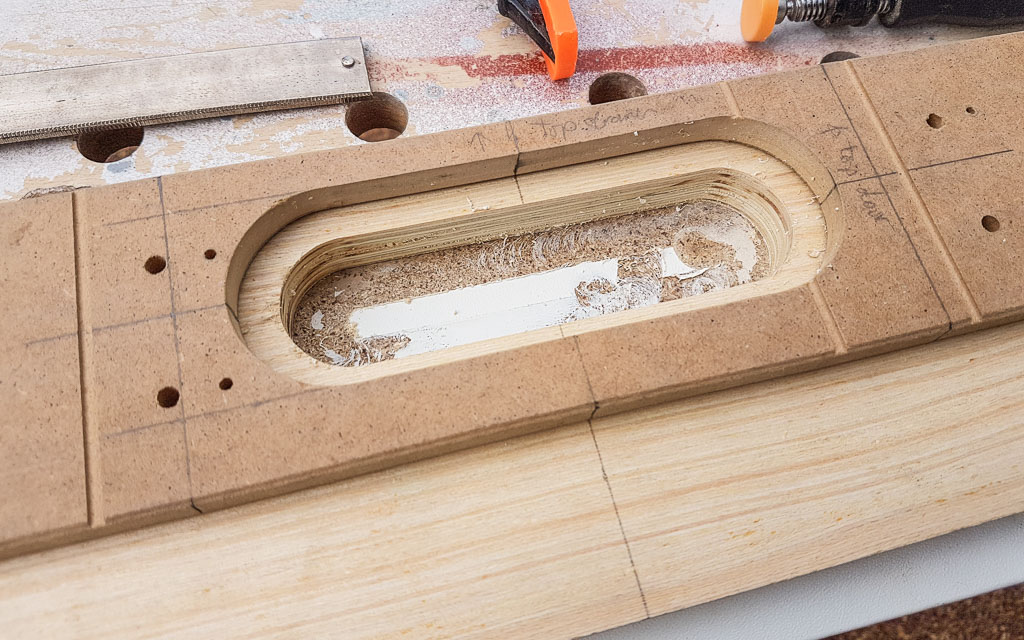

Next I started cutting a load of mortices using the Domino. All for 10mm dominos:

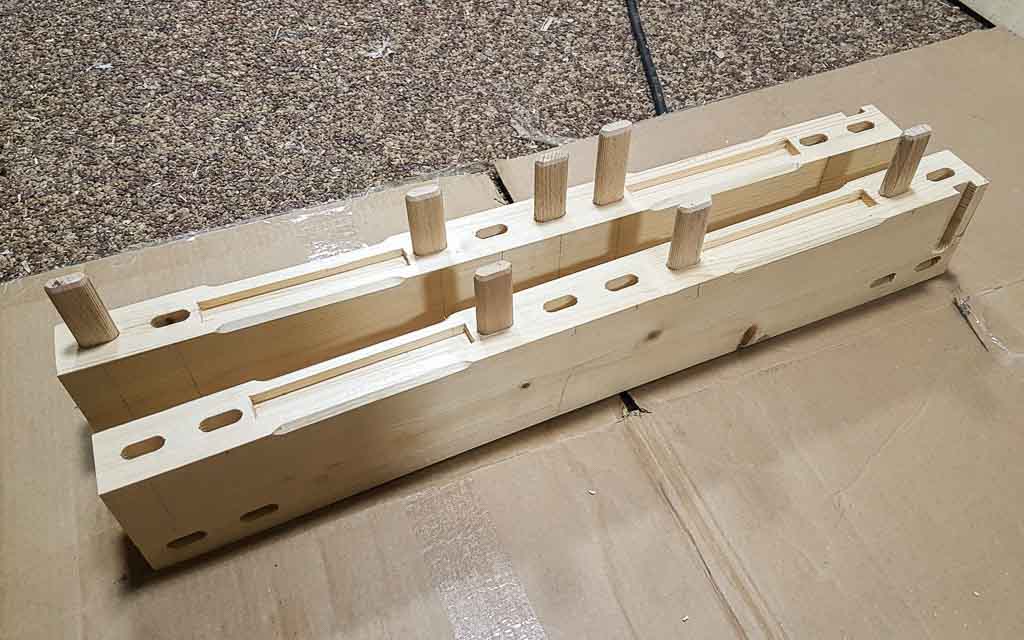

Lots of dominos!:

One side being dry fit together:

Horizontal rails and vertical rear support going together:

All dry fit:

From the front it should look a bit like this (though with doors and drawers):

From the side/rear:

I managed to source some reasonable quality 94x44mm redwood, and despite the fact it was already planed it did need some extra work. It was well worth the effort with the planer and thicknesser, and I ended up with 92x41.5mm stock that was pretty straight and square. An initial set of cuts for the sides fit together very well (the fat centre piece is two sections of stock glued together):

Next I started cutting a load of mortices using the Domino. All for 10mm dominos:

Lots of dominos!:

One side being dry fit together:

Horizontal rails and vertical rear support going together:

All dry fit: