gasman

Established Member

I have 'lurked' on this forum for a couple of years now without contributing a great deal apart from the odd comment. I have read many interesting and informative articles and threads and been amazed by the standard of some of the posted work. It has been inspiring and I thank all the contributors for a truly great woodworking resource.

Anyway, I thought I would start to contribute a bit more, beginnning with a WIP for my latest project. I make, amongst other things, elaborate jewellery cabinets as a hobby using combinations of 2,3 or 4 contrasting woods. I will post some old work when I get home and can dig out some images...

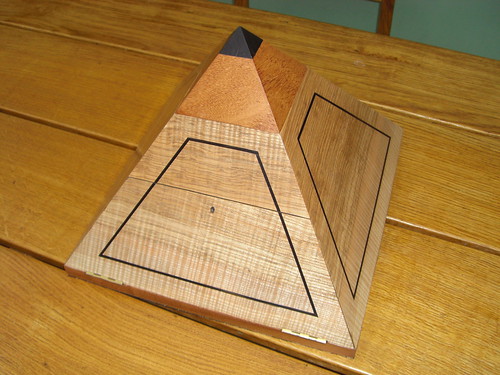

I confess to plagiarizing other people's work for ideas etc and have a couple of great books including a fabulous book called '400 Wooden Boxes: The Fine Art of Concealment and Containment' which I get great ideas from. For this particular piece, which is going to be my Niece's 18th birthday present, I am going to copy a box of Eugene Watson called 'Ziggurat box' (I believe ziggurats are the stepped pyramids found in Egypt and Iran)

[/img]

[/img]

Each level lifts off to reveal the contents of the level underneath. I like putting secret compartments or hidden bits in so I may tinker with the design. The triangular pieces in each corner I believe are abalone in the photo but I will use a contrasting wood. They act as handles to lift off each layer, plus they actually go through the wall and act as a support for the layer above too.

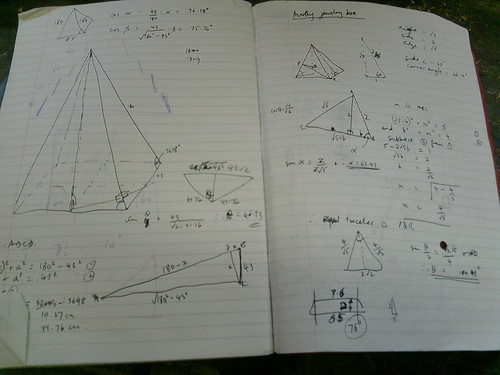

I have previously made a pyramidal jewellery cabinet (pictures to follow) - but it was a square pyramid with each face an equilateral triangle. This made the maths relatively straightforward for cutting the angles for the sides (60 degrees) and the bevel on each edge of the sides (54.7 degrees). The problem with this ziggurat is that the pyramid has to be alot 'steeper' because of the stepped nature of the sides so that overall it looks like the same sort of height/width ratio as an equilateral square pyramid. Not sure if I have explained myself well but anyway.... after alot of geometrical calculations on bits of paper, I have based each of the 4 triangular sides on an isoceles triangle with a 320mm base and 670mm sides. If I use timber 10 mm thick and 60 mm wide, this should mean I end up with a 320 mm square pyramid, with 5 levels, overall height 282 mm and a top 90 mm square. The maths is a bit more complex so that the angle that each side piece need to be cut at is 76.2 degrees, the bevel on the side edge of each side is 46.7 degrees and the bevel on the to and bottom of each side piece is 75.7 degrees. I will check all this again before the first cut! We shall see!

As to the wood, Eugene Watson makes his boxes from exotic species like bubinga and curly maple but I only have a very small amount of bubinga leftover. However, I do have some quartersawn ash, which looks lovely when it is contrasted with ebony or bubinga, and also some striking quartersawn oak left over from previous projects. Will decide tonight and cut the first lot of wood over the weekend.

My workshop has quite a bit of Festool, but the workhorse is a Record C26 Universal with a thin kerf CMT blade, which I have been very pleased with, and a 12 inch makita thicknesser so I do not have to keep changing the planer/thicknesser. Need new blades for both of them

More to follow....

Anyway, I thought I would start to contribute a bit more, beginnning with a WIP for my latest project. I make, amongst other things, elaborate jewellery cabinets as a hobby using combinations of 2,3 or 4 contrasting woods. I will post some old work when I get home and can dig out some images...

I confess to plagiarizing other people's work for ideas etc and have a couple of great books including a fabulous book called '400 Wooden Boxes: The Fine Art of Concealment and Containment' which I get great ideas from. For this particular piece, which is going to be my Niece's 18th birthday present, I am going to copy a box of Eugene Watson called 'Ziggurat box' (I believe ziggurats are the stepped pyramids found in Egypt and Iran)

Each level lifts off to reveal the contents of the level underneath. I like putting secret compartments or hidden bits in so I may tinker with the design. The triangular pieces in each corner I believe are abalone in the photo but I will use a contrasting wood. They act as handles to lift off each layer, plus they actually go through the wall and act as a support for the layer above too.

I have previously made a pyramidal jewellery cabinet (pictures to follow) - but it was a square pyramid with each face an equilateral triangle. This made the maths relatively straightforward for cutting the angles for the sides (60 degrees) and the bevel on each edge of the sides (54.7 degrees). The problem with this ziggurat is that the pyramid has to be alot 'steeper' because of the stepped nature of the sides so that overall it looks like the same sort of height/width ratio as an equilateral square pyramid. Not sure if I have explained myself well but anyway.... after alot of geometrical calculations on bits of paper, I have based each of the 4 triangular sides on an isoceles triangle with a 320mm base and 670mm sides. If I use timber 10 mm thick and 60 mm wide, this should mean I end up with a 320 mm square pyramid, with 5 levels, overall height 282 mm and a top 90 mm square. The maths is a bit more complex so that the angle that each side piece need to be cut at is 76.2 degrees, the bevel on the side edge of each side is 46.7 degrees and the bevel on the to and bottom of each side piece is 75.7 degrees. I will check all this again before the first cut! We shall see!

As to the wood, Eugene Watson makes his boxes from exotic species like bubinga and curly maple but I only have a very small amount of bubinga leftover. However, I do have some quartersawn ash, which looks lovely when it is contrasted with ebony or bubinga, and also some striking quartersawn oak left over from previous projects. Will decide tonight and cut the first lot of wood over the weekend.

My workshop has quite a bit of Festool, but the workhorse is a Record C26 Universal with a thin kerf CMT blade, which I have been very pleased with, and a 12 inch makita thicknesser so I do not have to keep changing the planer/thicknesser. Need new blades for both of them

More to follow....