You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why No Planer Thicknesser / Saw Combination machines ?

- Thread starter flanajb

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

katellwood

Established Member

katellwood":2wz559pj said:I'm on my second combi and for a one man band/hobbiest they are excellent

My first was a Lurem C210B, cast alloy saw/spindle and cast iron planer thicknesser tables. I bought it in 1987 for £750 and sold it in 2005 for £900.

My second and a replacement for the Lurem is a Felder BF5 1986 vintage. all cast iron with three motors, an excellent machine. the 12" wide P/T is a distinct advantage and the tilting spindle moulder makes this machine much more versatile

Only waiting now for retirement when I plan to opt for a upgraded felder with a longer sliding table.

One other thing I have found with both my combi's is that the space needed to increase the sheet ripping facility is not wasted as it is the planer beds. on a standalone saw with a large rip capacity this space in my opinion is often wasted

Nice to see this has been resurrected

For those that are interested my combi's so far

First my Lurem

Then my first felder

Then my current felder

For a small workshop I don't think you can fault them.

Most dedicated panel saws have the cast top then a sheet metal piece to the right of the blade, with a combi this is substituted by the planer tables (yes I appreciate with a single saw unit it can go up against a wall)

With regards to the spindle, very few stand alones have a sliding table of this length. I have found this exceptional for planing perfectly straight and square large pieces of timber for edging using a spindle block (much better than attempting to balance and hold tight to the fence when going over the surfacer) in addition with a tilting spindle bevels can be carried out with greater accuracy.

Finally, since getting my current felder with the sliding table and outrigger I have not used the RAS once

Giff

Established Member

I haven't got a combi but considered it. If I did I would put it on a turntable to make best use of a smallish space. I have made one for my bandsaw and it works well.

heimlaga

Established Member

I have a Stenberg planer/thicknesser/spindle moulder/table saw combination. Manufactured in Stockholm in 1957. The spindle moulder and table saw were optional so some machines turn up without one or the other. Usually without spindle moulder.

I also think AB Naula OY in Jakobstad in Finland made a planer/thicknesser/saw combination in the early 50-ies.

Felder certainly made such a combination in the 70-ies or 80-ies sometimes.

However I prefere all four in one machine.....or if I had room enough for separates with the same capacity as the Stenberg that would be my choice. However a 610mm planer and a 610 mm thicknesser and a 400mm/5hp table saw with sliding table and a 3hp spindle moulder would take up quite a bit of space.

I also think AB Naula OY in Jakobstad in Finland made a planer/thicknesser/saw combination in the early 50-ies.

Felder certainly made such a combination in the 70-ies or 80-ies sometimes.

However I prefere all four in one machine.....or if I had room enough for separates with the same capacity as the Stenberg that would be my choice. However a 610mm planer and a 610 mm thicknesser and a 400mm/5hp table saw with sliding table and a 3hp spindle moulder would take up quite a bit of space.

heimlaga":1nryjump said:I have a Stenberg planer/thicknesser/spindle moulder/table saw combination. Manufactured in Stockholm in 1957. The spindle moulder and table saw were optional so some machines turn up without one or the other. Usually without spindle moulder.

I also think AB Naula OY in Jakobstad in Finland made a planer/thicknesser/saw combination in the early 50-ies.

Felder certainly made such a combination in the 70-ies or 80-ies sometimes.

However I prefere all four in one machine.....or if I had room enough for separates with the same capacity as the Stenberg that would be my choice. However a 610mm planer and a 610 mm thicknesser and a 400mm/5hp table saw with sliding table and a 3hp spindle moulder would take up quite a bit of space.

That's a pretty unusual combination machine, sounds very very capable!

£199.00

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£34.99 (£3.50 / count)

£39.99 (£4.00 / count)

VonHaus Chisel Set - 10pcs Woodworking Tools Set - Wood Carving Tools, Wood Chisel Sets with Sharpening Stone, Honing Guide and Storage Case

VonHaus UK

£15.99 (£1.60 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£10.10

£15.48

Portwest Browguard with Clear Visor, Size: One Size, Colour: Clear, PW91CLR

Amazon.co.uk

£9.99 (£1.00 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£16.99

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£10.19 (£0.39 / count)

£11.99 (£0.46 / count)

Nicpro Carpenter Pencil with Sharpener, Mechanical Carpenter Pencils Set with 26 Refills, Case, Deep Hole Marker Construction Pencils Heavy Duty Woodworking Pencils for Architect (Black, Red)

NicproShop EU

katellwood":16cpbqt5 said:katellwood":16cpbqt5 said:I'm on my second combi and for a one man band/hobbiest they are excellent

My first was a Lurem C210B, cast alloy saw/spindle and cast iron planer thicknesser tables. I bought it in 1987 for £750 and sold it in 2005 for £900.

My second and a replacement for the Lurem is a Felder BF5 1986 vintage. all cast iron with three motors, an excellent machine. the 12" wide P/T is a distinct advantage and the tilting spindle moulder makes this machine much more versatile

Only waiting now for retirement when I plan to opt for a upgraded felder with a longer sliding table.

One other thing I have found with both my combi's is that the space needed to increase the sheet ripping facility is not wasted as it is the planer beds. on a standalone saw with a large rip capacity this space in my opinion is often wasted

Nice to see this has been resurrected

For those that are interested my combi's so far

First my Lurem

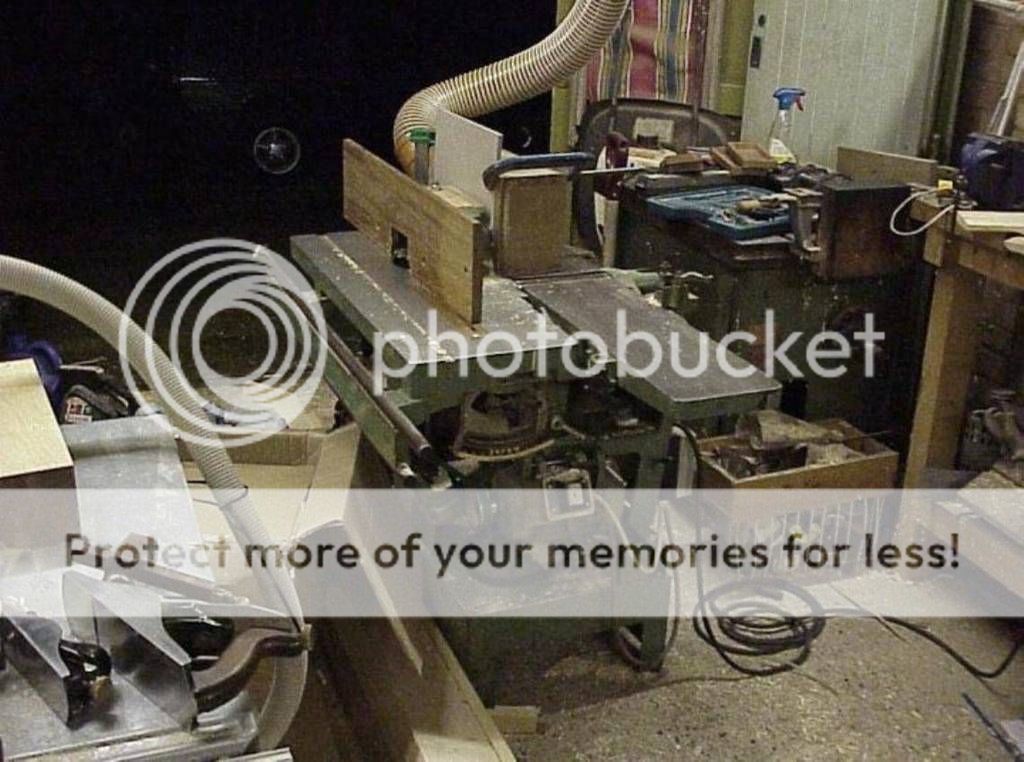

Then my first felder

Then my current felder

For a small workshop I don't think you can fault them.

Most dedicated panel saws have the cast top then a sheet metal piece to the right of the blade, with a combi this is substituted by the planer tables (yes I appreciate with a single saw unit it can go up against a wall)

With regards to the spindle, very few stand alones have a sliding table of this length. I have found this exceptional for planing perfectly straight and square large pieces of timber for edging using a spindle block (much better than attempting to balance and hold tight to the fence when going over the surfacer) in addition with a tilting spindle bevels can be carried out with greater accuracy.

Finally, since getting my current felder with the sliding table and outrigger I have not used the RAS once

how does the 1st felder stack up against its newer replacement?

Wildman

Established Member

There are numerous combination machines around, from coronet, Kity and on to those in industrial scale with 5hp three phase motors.

katellwood

Established Member

marcros":2yp8ionx said:katellwood":2yp8ionx said:katellwood":2yp8ionx said:I'm on my second combi and for a one man band/hobbiest they are excellent

My first was a Lurem C210B, cast alloy saw/spindle and cast iron planer thicknesser tables. I bought it in 1987 for £750 and sold it in 2005 for £900.

My second and a replacement for the Lurem is a Felder BF5 1986 vintage. all cast iron with three motors, an excellent machine. the 12" wide P/T is a distinct advantage and the tilting spindle moulder makes this machine much more versatile

Only waiting now for retirement when I plan to opt for a upgraded felder with a longer sliding table.

One other thing I have found with both my combi's is that the space needed to increase the sheet ripping facility is not wasted as it is the planer beds. on a standalone saw with a large rip capacity this space in my opinion is often wasted

Nice to see this has been resurrected

For those that are interested my combi's so far

First my Lurem

Then my first felder

Then my current felder

For a small workshop I don't think you can fault them.

Most dedicated panel saws have the cast top then a sheet metal piece to the right of the blade, with a combi this is substituted by the planer tables (yes I appreciate with a single saw unit it can go up against a wall)

With regards to the spindle, very few stand alones have a sliding table of this length. I have found this exceptional for planing perfectly straight and square large pieces of timber for edging using a spindle block (much better than attempting to balance and hold tight to the fence when going over the surfacer) in addition with a tilting spindle bevels can be carried out with greater accuracy.

Finally, since getting my current felder with the sliding table and outrigger I have not used the RAS once

how does the 1st felder stack up against its newer replacement?

I was trained and bought up on Wadkins, Robinsons and Dominions and on purchasing the Lurem was impressed how versatile it was. that being said, with only a 8" planer thicknesser it was a little bit limited along with no/minimal dust extraction (at the time it also did all my morticing with a chuck attached to the planer block and a table linked to the thicknesser table)

Felder no 1 was a complete step up, it was all cast iron including the main frame, very accurate with adjustments everywhere and easy to maintain (I replaced the planer block bearings quite easily) it felt rock solid although a bit agricultural, downfalls where that you had to remove the spindle shaft between uses as it would not fall below the table and tilting on both saw and spindle was via a lever (and gentle taps with a mallet). dust extraction was basic but did the job. But having said all that it did the job admirably maintaining all settings.

Felder no 2 again another step up, four knife cutter block with easy change facility (and reasonably cheap blades via ebay). A sliding table that glides extremely smoothly, Fences that are easy to set and all with micro adjustment, two speed thicknessing, extension tables that fit on the ends of all beds and a tilting spindle with router shaft facility. extraction not perfect but extremely effective.

The 7 series is a pleasure to use and since the demise of Knapp arguably the best on the market

All three combi's I have had have all been manoeuvrable via wheel kits, the last two being extremely heavy.

Similar threads

- Replies

- 14

- Views

- 787