I would like to ask what is the most appropriate hand tool or a procedure with hand tools to round corners uniformly to get 2 - 3 mm radius (e.g. on table legs or tabletop edge)?

How much of this do you have to do and how long are the individual pieces?

If you don't have miles of edges to do and the pieces are long enough for a #4 plane to register, I would use that, at least initially. A good block plane might be better but I don't have one. Maybe follow up with a scratch stock and/or abrasive paper.

If the pieces are short I might go straight to a scratch stock.

If you have a lot of this to do you might use it as an excuse to buy an old moulding plane, or maybe make something. I have no great experience of that though.

The second question is what hand tools can be used to create longer sliding dovetails ( e.g. 60 cm wide board that is dovetailed to the tabletop of the office desk like in the picture below). I cannot saw this width with a hand saw.

Why do you say you cannot saw this wide with a hand saw? What problems do you have? Is the problem with the groove or the tail that fits in the groove? I went through this learning curve a couple of years ago and I do this with a hand saw so I will describe how I do it. My process for the groove is:

1. Score the edge of the groove with a knife.

2. Emphasise this with a chisel to make a shallow knife wall. This can be at 90 degrees to the surface - I don't try to establish the angle for the side of the groove at this stage.

3. Clamp on a guide I made from a scrap of 4x2. The guide has a sloping side at the desired angle (1 in 6 in my case) which is easily created with a hand plane. I recessed some strong magnets in that sloping face and covered it with a thin plate of wood. (I was going to write "thin veneer" but that would imply something much thinner than I actually used. My magnets were string enough, and I used enough of them, that the plate did not have to be ultra thin.)

4. Saw the edge of the groove by running the saw against the guide. The magnets keep the saw in line. I typically use my cheap tennon saw but any saw would probably do.

5. Repeat this for the other side of the groove.

6. Remove the waste with a chisel. On a wide board you probably need to work bevel down.

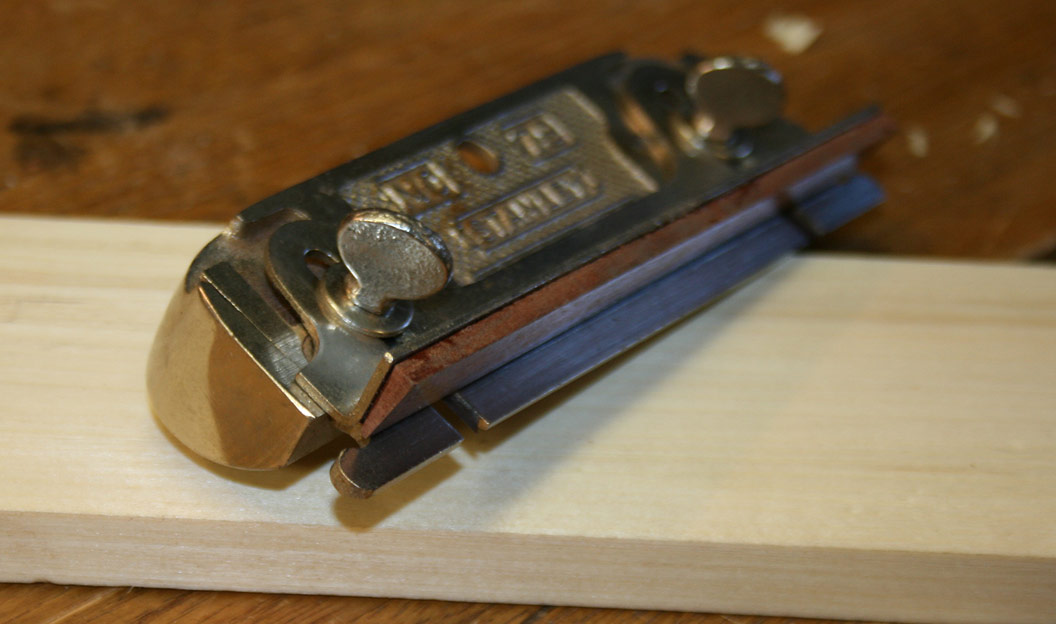

7. Clean out & flatten the bottom of the groove with a hand router if you have one. I didn't have one for my first attempts. Now I have a router plane this job is much easier, but it is possible to use just a chisel if you are patient.

To cut the tail part on the edge of the other board I clamp a piece of scrap on the side of that board flush with the edge. This gives a platform to which I can clamp my saw guide. I can then cut the sides of the tail in basically the same was as I cut the sides of the groove, but usually I don't make a knife wall first. I find it hard to create a neat knife wall on end grain and anyway being neat there does not matter so much because that edge of the tail will never be seen, except at the very end. I would love to try a dovetail plane as suggested by heimlaga but I don't have one and have managed to get by without one so far so I will probably continue to do so.

Cutting the shoulders is straightforward but clamping a length of square stock in place to act as a saw guide makes it easier on a wide board.

Because the boards you are using are wide a tapered dovetail as suggested by thetyreman is a good approach. It makes assembly much easier.

Note that this describes how I do it. A professional would surely take a different approach but I don't have the skills of a pro.

Good luck!