JonnyD

Established Member

Been doing a bit more today started by ripping some stock to make the face frames in CND Beech which stands for colour no defect but in reality its pretty clean stock usually.

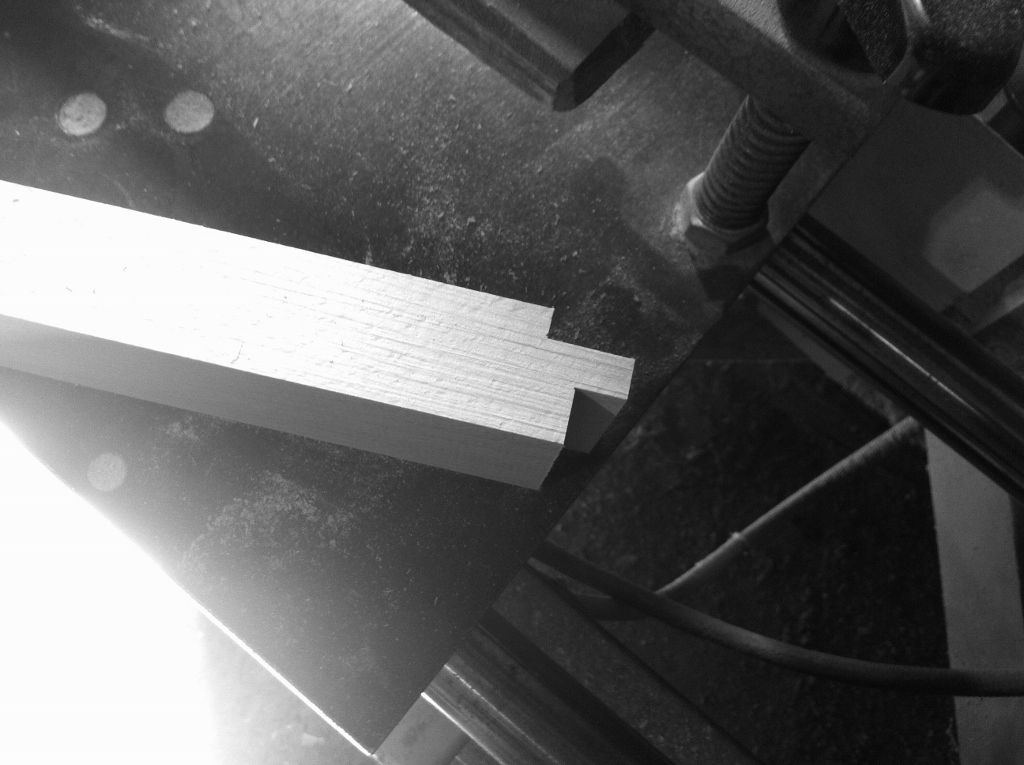

Sections were machined on the planer thicknesser

I prefer to do the widest face first and then thickness all of the pieces to thickness in this case 33mm

I then joint all the edges and thickness to width

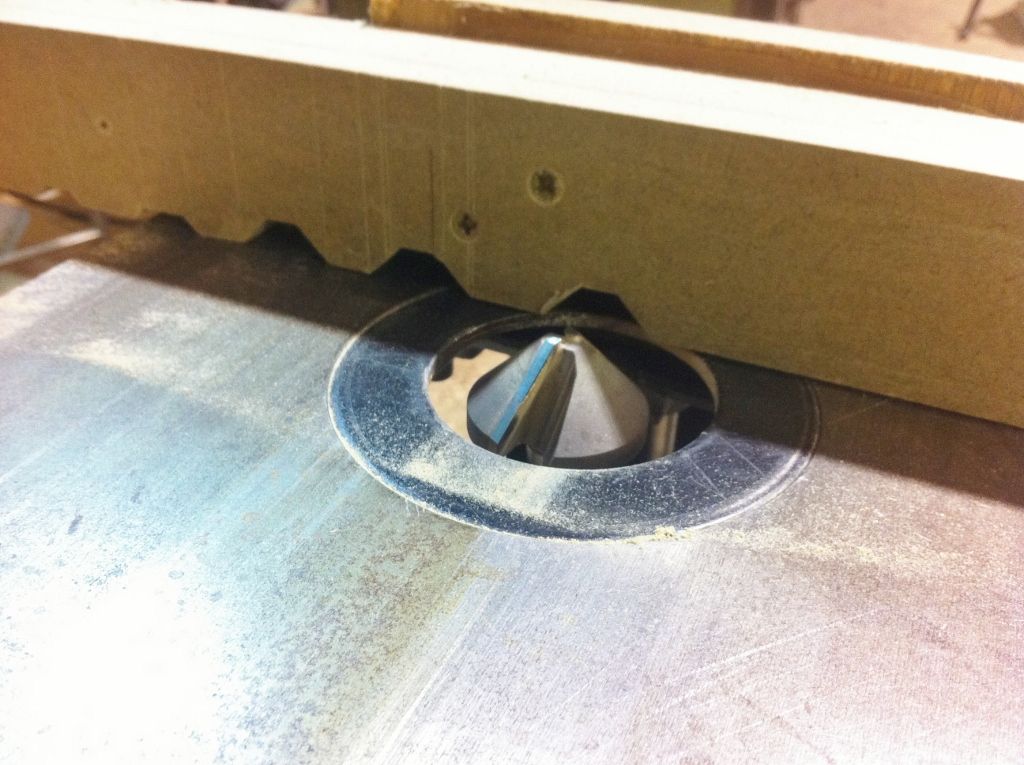

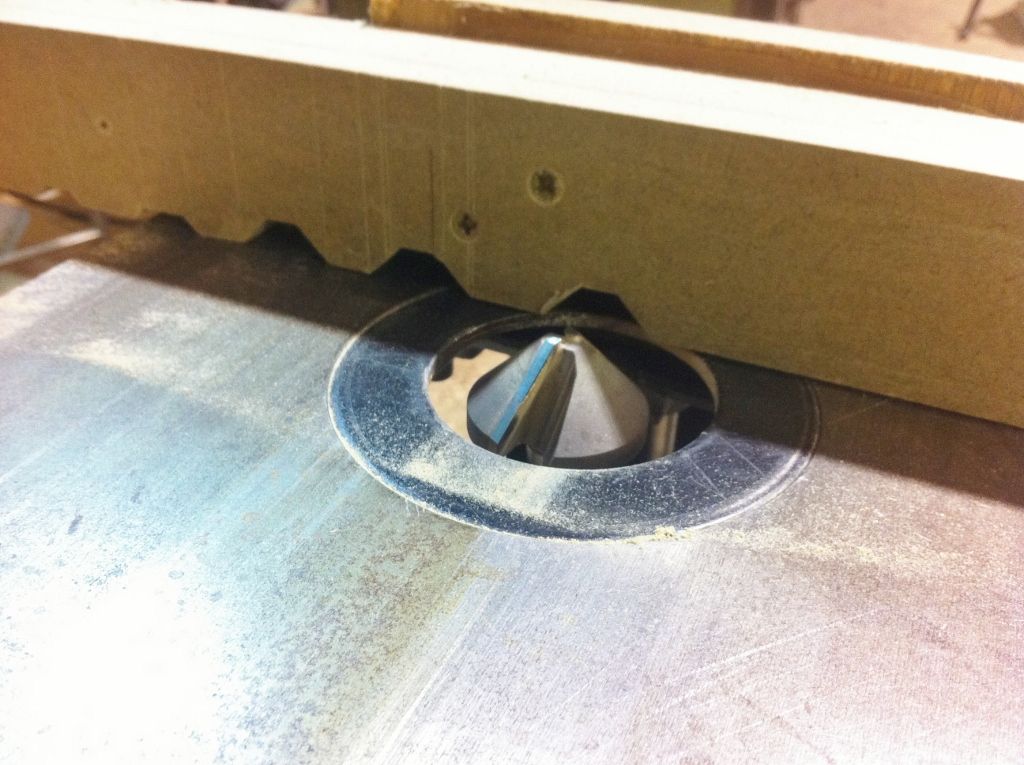

To start making the frames i cut the joints first before mouding the bead. A 45 degree cutter is used in the router table to do this. I decided to treat myself to a new squelch bit on the fence so i moved the fence along a bit and made a cut

A couple of lines are scribed on the fence to aid laying out the joints

The end cuts can be setup by aligning a piece of stock against the scribed line and the stop (a right angle of corian) attached to the fence

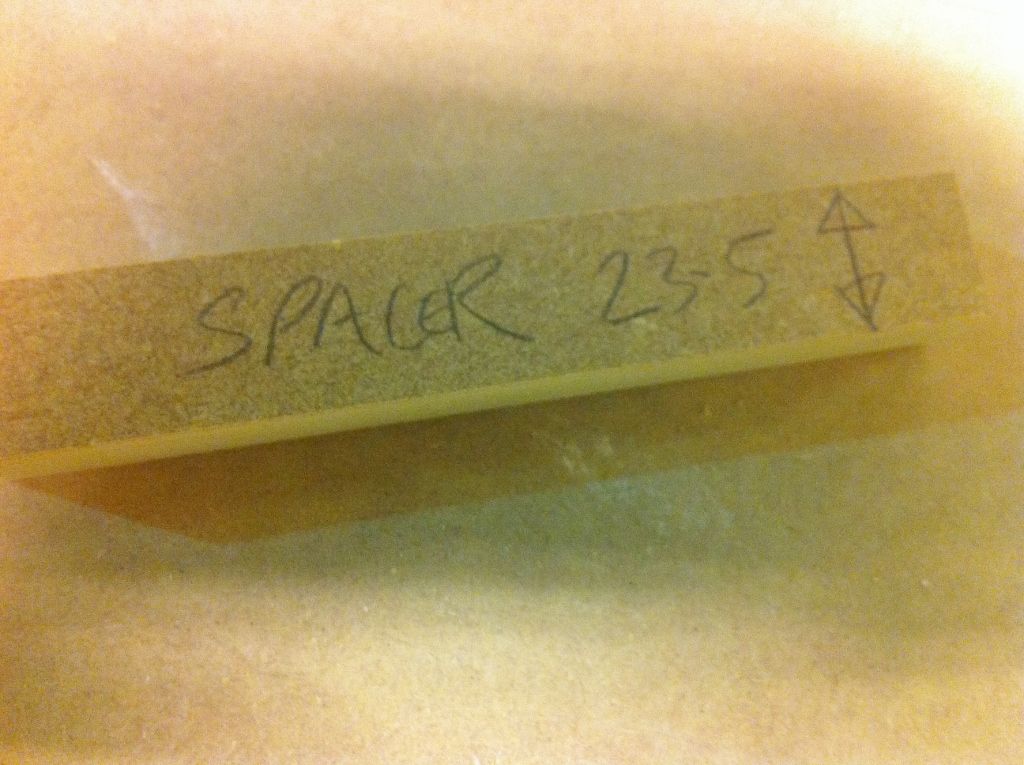

To do a notch in the middle of a board you need to know how wide the cut is in this case its 26.5mm

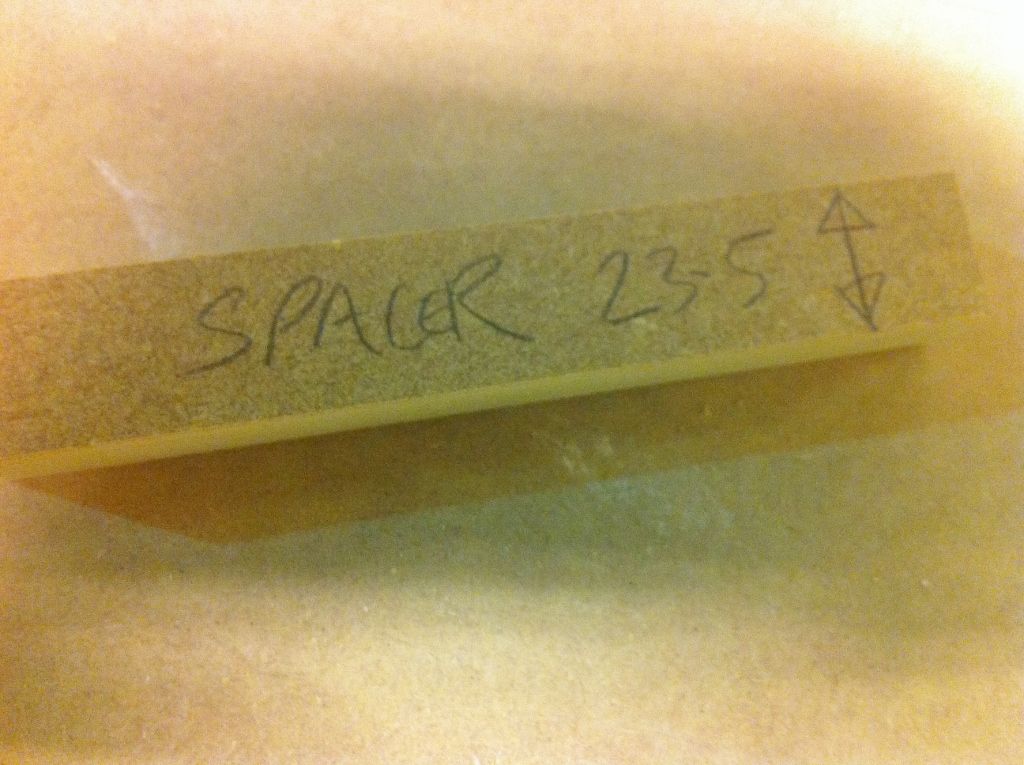

The stock for this part of the face frame is 50mm wide so a 23.5mm spacer is made on the table saw to allow the notch to be cut with one fence position

The joint is marked out and the first line aligned with the scribed mark on the fence and the stop positioned

First part of the joint is cut

The spacer is then inserted between the end of the stop and the stock and a second notch made which will be the exact size of the 50mm rail

The bit in the middle is taken out freehand

The end 45 degree cuts are done by moving the stop to the right place

I start with the outside frame

And then add the bits in the middle. This frame is in 1 section about 3 metres long

Thanks for looking

cheers

Jon

Sections were machined on the planer thicknesser

I prefer to do the widest face first and then thickness all of the pieces to thickness in this case 33mm

I then joint all the edges and thickness to width

To start making the frames i cut the joints first before mouding the bead. A 45 degree cutter is used in the router table to do this. I decided to treat myself to a new squelch bit on the fence so i moved the fence along a bit and made a cut

A couple of lines are scribed on the fence to aid laying out the joints

The end cuts can be setup by aligning a piece of stock against the scribed line and the stop (a right angle of corian) attached to the fence

To do a notch in the middle of a board you need to know how wide the cut is in this case its 26.5mm

The stock for this part of the face frame is 50mm wide so a 23.5mm spacer is made on the table saw to allow the notch to be cut with one fence position

The joint is marked out and the first line aligned with the scribed mark on the fence and the stop positioned

First part of the joint is cut

The spacer is then inserted between the end of the stop and the stock and a second notch made which will be the exact size of the 50mm rail

The bit in the middle is taken out freehand

The end 45 degree cuts are done by moving the stop to the right place

I start with the outside frame

And then add the bits in the middle. This frame is in 1 section about 3 metres long

Thanks for looking

cheers

Jon