Dibs-h

Established Member

I decided to start a new thread as it's about possible options as opposed to the one that will actually go on\in the workshop.

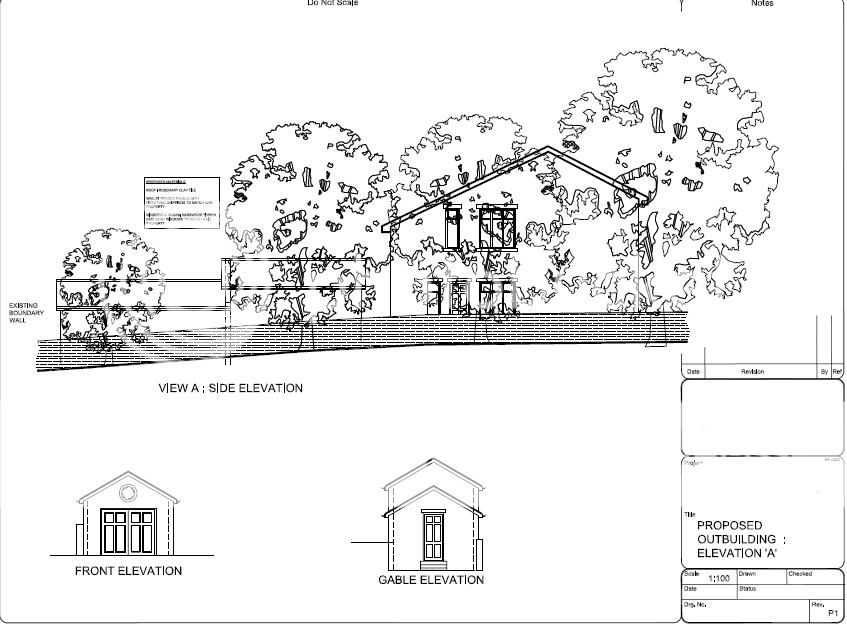

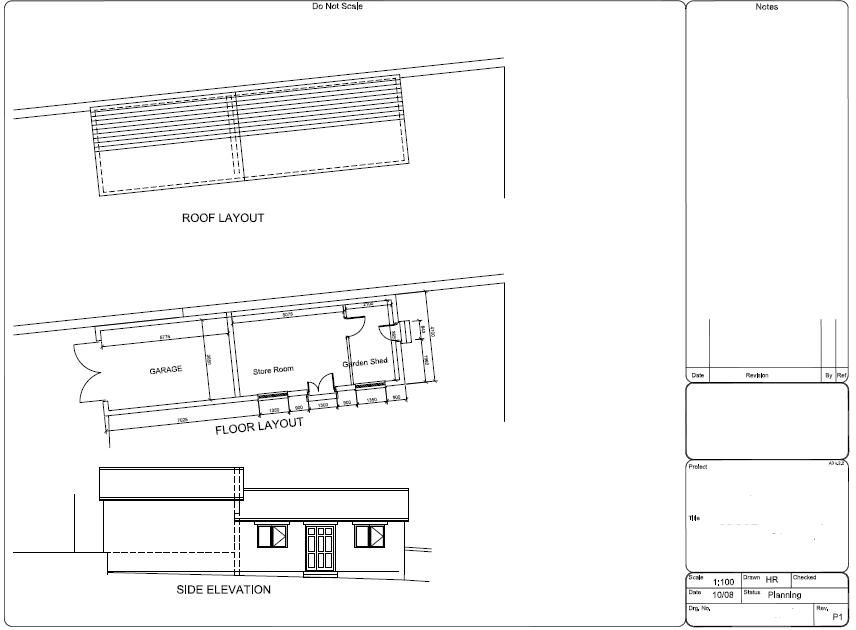

My workshop is to be 7.5m long by 4.5m wide. I don't want a low ceiling inside - so initially thoughts were along the lines of raised tie trusses, but the lateral thrust on the long walls became a concern. Especially as the SE was now suggesting building the walls with 9 inch blocks laid on their sides. Or double skin.

What threw a spanner in the works is the B\C chap suggesting it would make a grand "Granny Flat". Which got me thinking that whilst I have no intention of moving in my liftetime - looking back, there was a time when I never thought I'd be moving out of where I lived before - so why not think ahead and if I sell up, it certainly would make it an attractive proposition to a potential buyer.

So back to the conundrum -

Walls - outer single skin blockwork, with 4x2 timber inner skin (insulated between studs, vapour barriers, membrane etc. where necessary).

Roof - the SE has suggested steel I beams at ridge level and at almost eaves, with these bearing the loads from the rafters, etc. These would rest on the "gable" ends, so those might be double skin (or I'm thinking more along the lines of piers). He said he'd make sure that the beams would resist the bending moments in the horizontal plane.

Or, put 2 Queen trusses (I think that's the correct phrase) in at 1/3 and 2/3 and then a traditional roof? Now I think it would nicer than just an anonymous board ceiling. Not to mention that if (and it's a big if) if we ever moved - it would look far less "industrial". Any thoughts\advice? Also I'd be expecting to put piers where the Queen trusses would go.

If one was to use Queen trusses - I would only need 2, so get them made or make them oneself?

My workshop is to be 7.5m long by 4.5m wide. I don't want a low ceiling inside - so initially thoughts were along the lines of raised tie trusses, but the lateral thrust on the long walls became a concern. Especially as the SE was now suggesting building the walls with 9 inch blocks laid on their sides. Or double skin.

What threw a spanner in the works is the B\C chap suggesting it would make a grand "Granny Flat". Which got me thinking that whilst I have no intention of moving in my liftetime - looking back, there was a time when I never thought I'd be moving out of where I lived before - so why not think ahead and if I sell up, it certainly would make it an attractive proposition to a potential buyer.

So back to the conundrum -

Walls - outer single skin blockwork, with 4x2 timber inner skin (insulated between studs, vapour barriers, membrane etc. where necessary).

Roof - the SE has suggested steel I beams at ridge level and at almost eaves, with these bearing the loads from the rafters, etc. These would rest on the "gable" ends, so those might be double skin (or I'm thinking more along the lines of piers). He said he'd make sure that the beams would resist the bending moments in the horizontal plane.

Or, put 2 Queen trusses (I think that's the correct phrase) in at 1/3 and 2/3 and then a traditional roof? Now I think it would nicer than just an anonymous board ceiling. Not to mention that if (and it's a big if) if we ever moved - it would look far less "industrial". Any thoughts\advice? Also I'd be expecting to put piers where the Queen trusses would go.

If one was to use Queen trusses - I would only need 2, so get them made or make them oneself?