garywayne

Established Member

Just a quick question about shed corner construction.

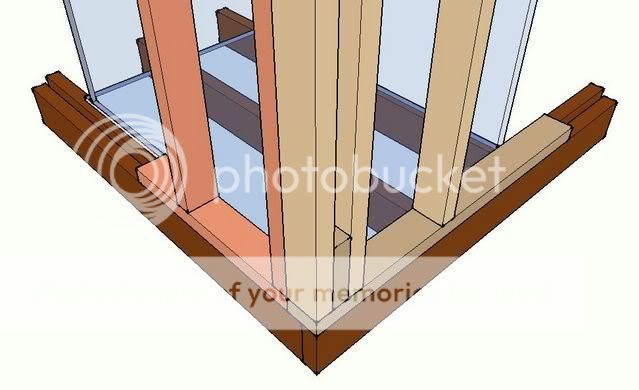

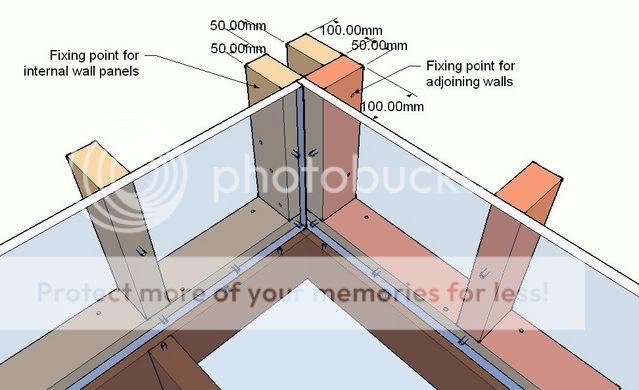

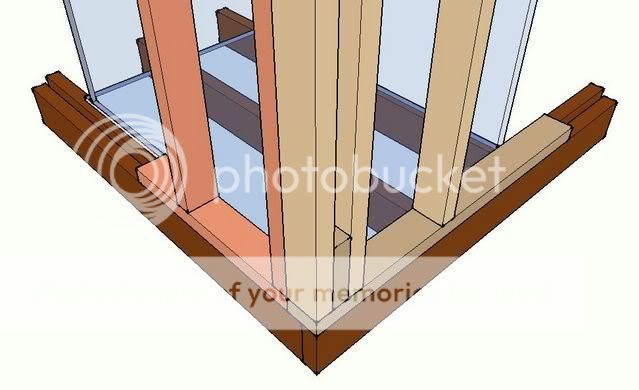

In this picture I am using 6" X 4" floor joists and 4" X 2" wall studding. To get support for the floorboards at the edges I have put a 1" gap between the two outer joists. Am I doing this wright? Also, I have put a piece of wood to space out the two uprights on one wall to make it wider than the adjoining wall, so that there is somewhere to secure the interior boards.

This all sounds confusing to me, so I don't expect it is very clear to you either. So, anything your not sure about, just ask.

In this picture I am using 6" X 4" floor joists and 4" X 2" wall studding. To get support for the floorboards at the edges I have put a 1" gap between the two outer joists. Am I doing this wright? Also, I have put a piece of wood to space out the two uprights on one wall to make it wider than the adjoining wall, so that there is somewhere to secure the interior boards.

This all sounds confusing to me, so I don't expect it is very clear to you either. So, anything your not sure about, just ask.