wizer

Established Member

- Joined

- 3 Mar 2005

- Messages

- 15,589

- Reaction score

- 1

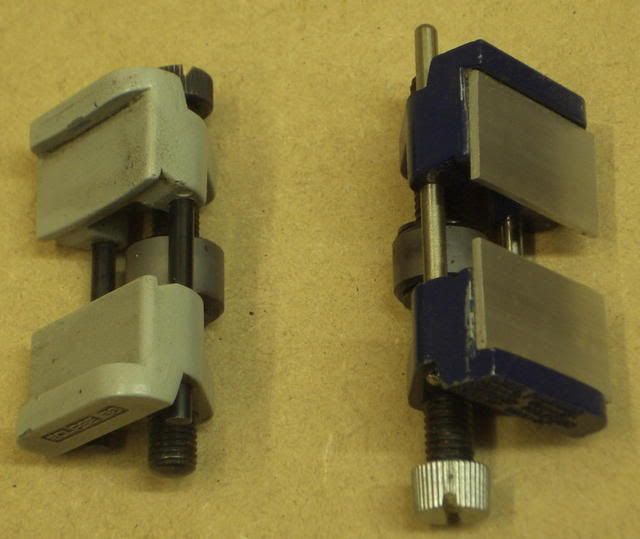

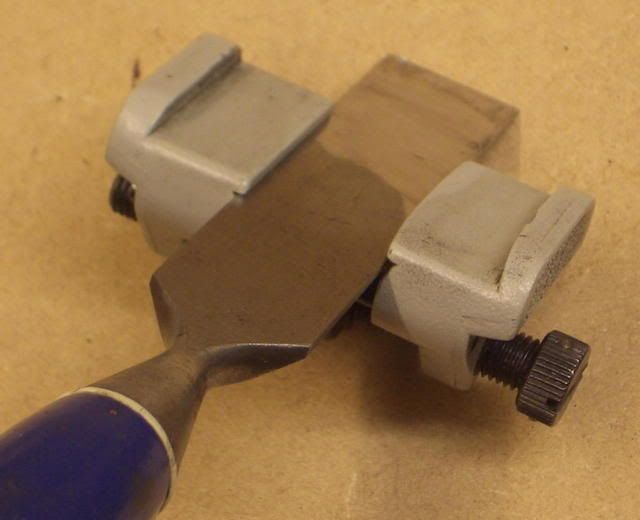

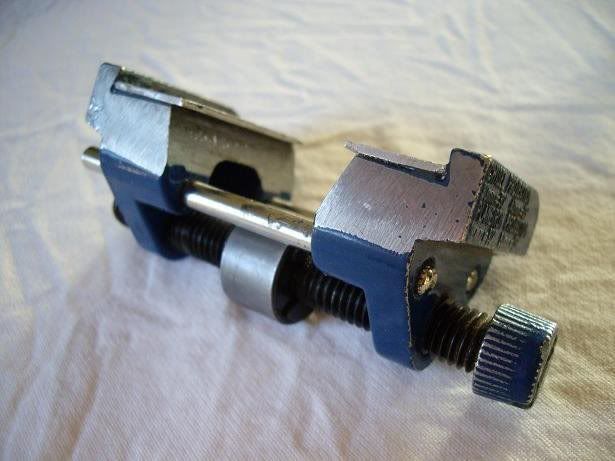

This is a hard one to explain. I got the small blade holder to sharpen the blades in my LN spokeshaves. When I put the blade into the holder, I am having problems setting it into the Mk.II Honing guide. The blade had a rounded top edge, which means it's hard to repeatably clamp square in the jig. Plus it's only held by RE magnets. Am I missing something, or should I invest in a different type of honing guide for these blades?

I'm aware that I should be able to hone freehand and that it's a valuable skill to have, etc, etc. But, really, i'd rather concentrate on making stuff (i know, i know).

TIA

I'm aware that I should be able to hone freehand and that it's a valuable skill to have, etc, etc. But, really, i'd rather concentrate on making stuff (i know, i know).

TIA