Corneel

Established Member

Looks good so far. From where I am looking it seems like the wedge fits perfectly. Are you going to chamfer the wedge too? That helps to avoid splintering in the long run and I think it looks neater.

Corneel":1vke23mi said:Looks good so far. From where I am looking it seems like the wedge fits perfectly. Are you going to chamfer the wedge too? That helps to avoid splintering in the long run and I think it looks neater.

swagman":34lrj515 said:I am still undecided on whether a rear tote is needed. Feedback welcome on the need to do so.

Stewie

AndyT":29wmftw8 said:swagman":29wmftw8 said:I am still undecided on whether a rear tote is needed. Feedback welcome on the need to do so.

Stewie

Looking at more ordinary planes for a moment, the shortest sort with a rear handle is a Jack plane at 15-17" long. This plane is only 12" now. Although you are calling it a Fore Plane it's clearly not going to have a deeply cambered iron, so there won't be the necessity of a handle to get a good push on it (to cut a thick shaving) as there is with a Jack/Fore plane. I imagine in use that it will feel more like a smoother - successive strokes may not even all be in the same direction. So there is less need for a handle.

But then, your stock looks quite wide, so unless you have very large hands, it will be difficult to pick up.

Overall, I think I would not fit a handle but I would consider giving the body some shaping and tapering, along the lines of a boat/coffin shaped smoother, to make it easier to pick up and hold.

MIGNAL":1c4m0a7j said:

AndyT":102jppgy said:You could always go very traditional - back to Roman design - and use through holes to make gripping easier. This is the Goodmanham plane, which is about the same length as yours:

More here:

http://www.handplane.com/906/the-ancient-roman-plane-of-yorkshire-wolds/

(I'm sure yours will look a bit smarter!)

swagman":2nojgrp4 said:Apart from Philly. Out of curiosity is their any other forum members that have made a wooden bodied bench plane using the traditional technique of mortising out a single block of wood.

Stewie;

swagman":25oq5cdp said:A bit of a teaser for those well versed in traditional bench planes. Later down the track, if I need to re-flatten the sole of this toothing plane.

Will the mouth opening in front of the blade;

1/Increase in size.

2/Stay the same size.

3/Reduce in size.

Stewie;

AndyT":2liidlch said:swagman":2liidlch said:A bit of a teaser for those well versed in traditional bench planes. Later down the track, if I need to re-flatten the sole of this toothing plane.

Will the mouth opening in front of the blade;

1/Increase in size.

2/Stay the same size.

3/Reduce in size.

Stewie;

As nobody else has answered, I'll stick my neck out - the answer is No 1 - the opening will increase in size.

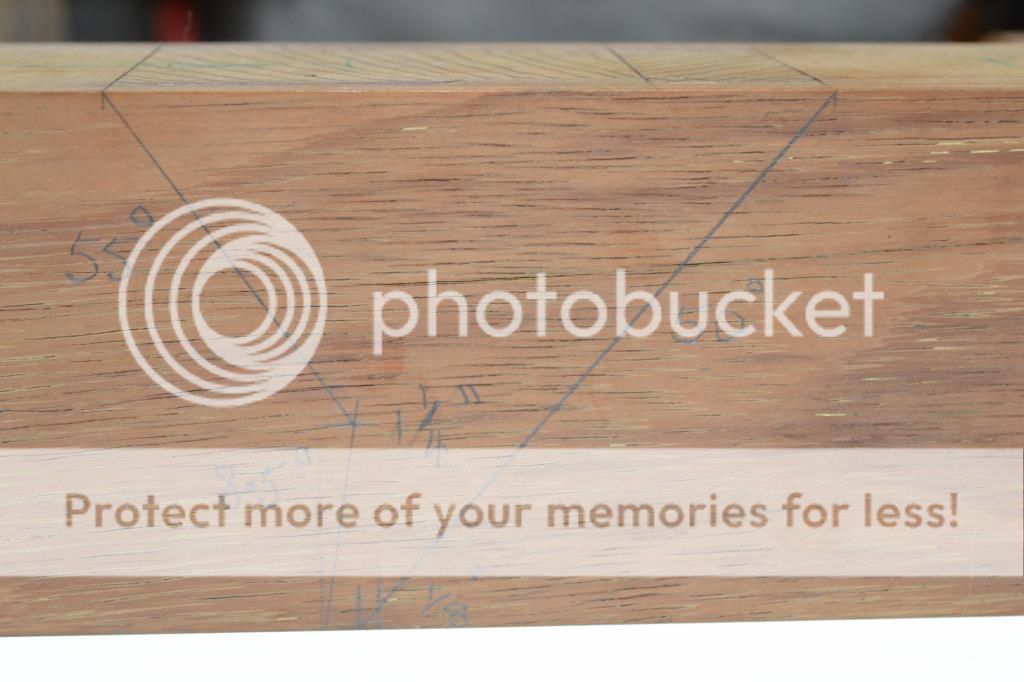

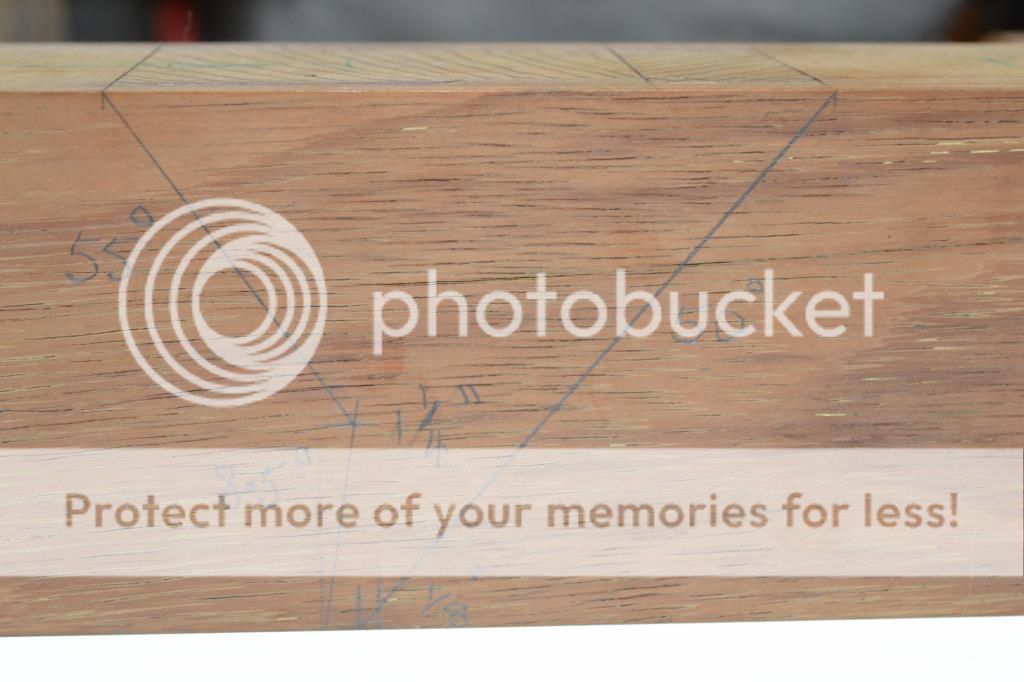

Borrowing your own picture for a moment,

the starting mouth size is with the sole at the bottom of the block.

If you move the sole up the picture (by planing wood off the bottom) you reach a wider place on the tapered mortice (mouth) so the gap in front of the blade will be bigger.

bugbear":2n0hheb5 said:I'm late to this thread; how did you choose the bedding angle?

All the 19th and 20th C toothing planes I've seen bed at 80 to 87 degrees (i.e. very close to vertical).

BugBear

swagman":9l8p6io6 said:bugbear":9l8p6io6 said:I'm late to this thread; how did you choose the bedding angle?

All the 19th and 20th C toothing planes I've seen bed at 80 to 87 degrees (i.e. very close to vertical).

BugBear

Hi bugbear. Process of elimination. I have previously built toothing planes bedded at 55, 60, & 90*. For the purpose of dressing the surface of curly grained timber IMO the 55 performed this task best of all 3. Keep in mind that the single irons I am using are tapered 3* so the actual approach angle is 52*.

Stewie;

Enter your email address to join: