swagman

Established Member

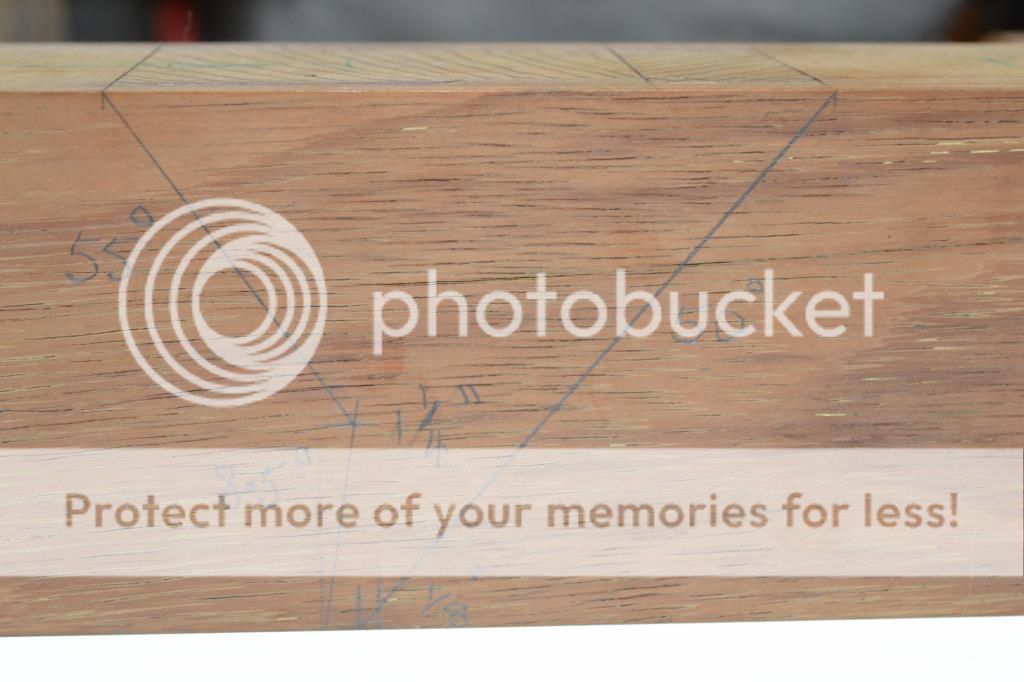

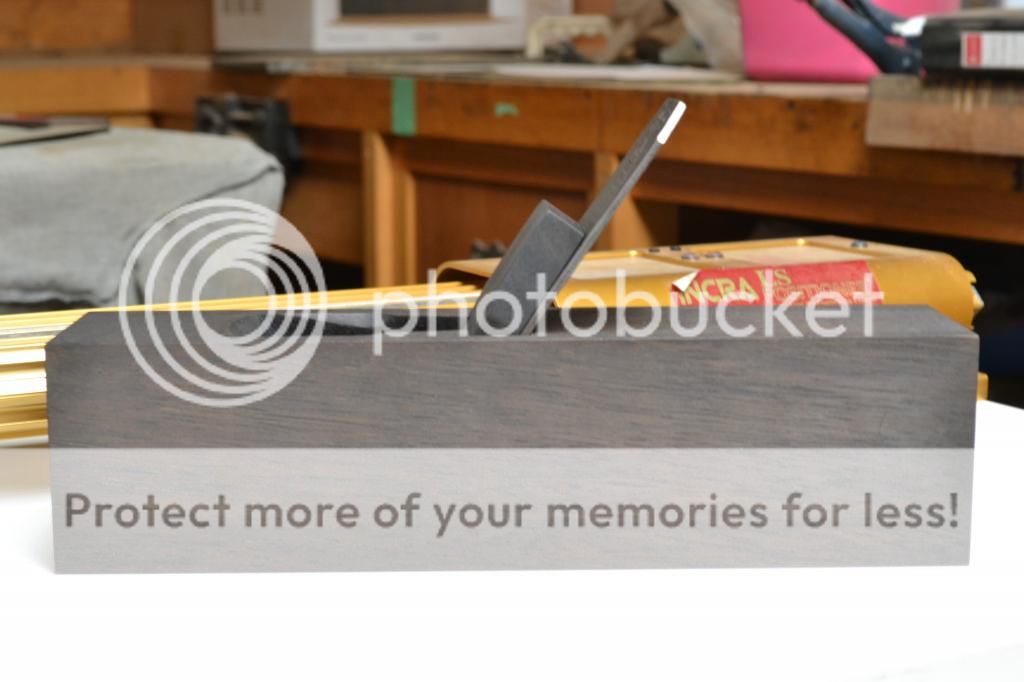

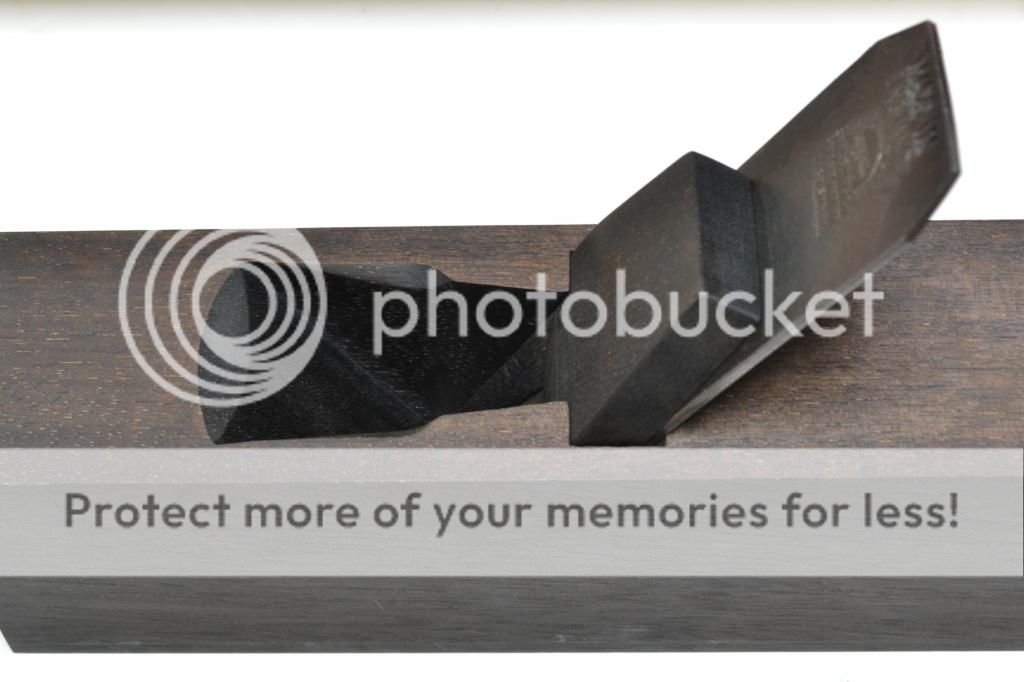

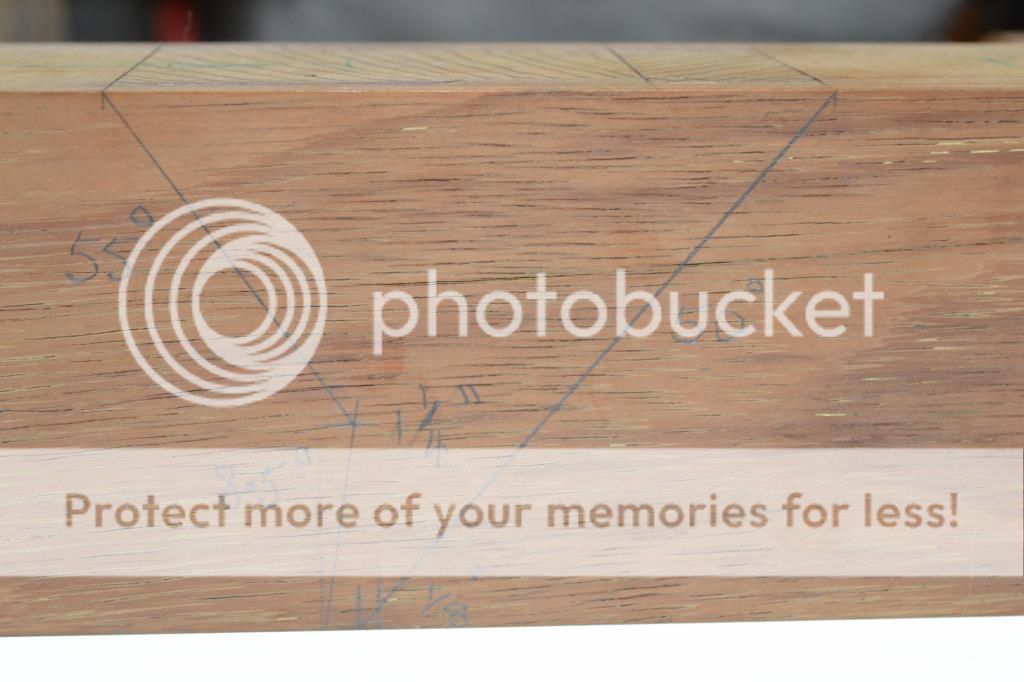

Hi all. It been well over 2 years since I made my last traditional wooden bodied hand plane, and I saw a need to build one for my own personal use that was at 22 inches in length and fitted with a 2 inch wide toothing blade.

The wood chosen to use is Merbau. IMO its a very good choice of timber for making traditional hand planes. Its much heavier and denser than European Beech, rates quite high on the yanka hardness scale, is high in natural oils, and exhibits very little change in wood movement.

At this stage I have the cut block to size, all sides & both ends have been dressed flat, and the area to be mortised out has been marked. Its a project that will take some time to complete as it will need to work around my primary interest at the moment which is backsaw making.

Stewie;

The wood chosen to use is Merbau. IMO its a very good choice of timber for making traditional hand planes. Its much heavier and denser than European Beech, rates quite high on the yanka hardness scale, is high in natural oils, and exhibits very little change in wood movement.

At this stage I have the cut block to size, all sides & both ends have been dressed flat, and the area to be mortised out has been marked. Its a project that will take some time to complete as it will need to work around my primary interest at the moment which is backsaw making.

Stewie;