Hi All,

I have been busy recently and not had time to contribute to threads on the forum. I have read this thread with some interest as my friend Boffin53 has been perfecting his latest wood turning accessory with some trials down at my workshop where we have deliberately made use of my Fox midi lathe so as to assure any interested party that the jig can be used on a small lathe as well as any larger machine.

I can see you are all in need of some WIP photographs and therefore i have turned the embrio of a box to show how the threading jig is set up and operated.

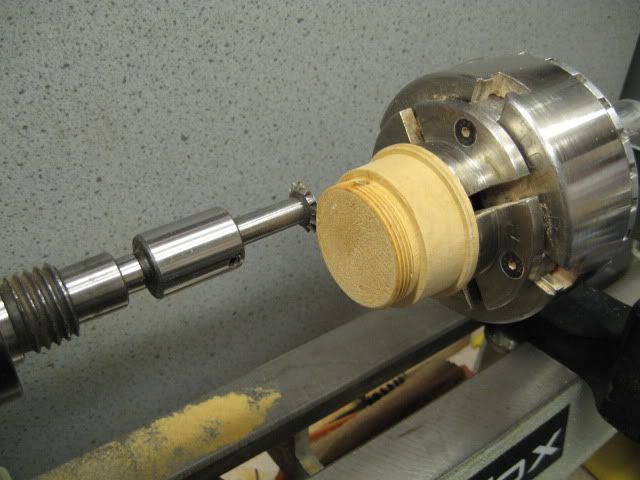

This picture shows the cutter adjusted to cut the external thread on the male lid section.

Here is a close up of the cutter and timber

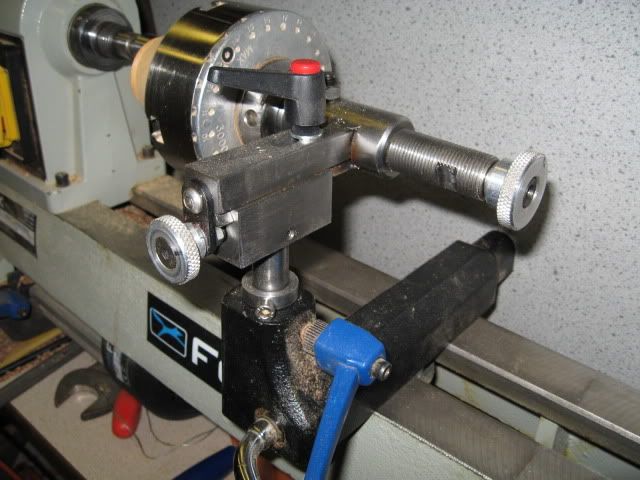

This picture shows the overall set up of the jig on the lathe

The next photo shows the set up for cutting the internal thread in the base of the box.

I have included a further picture of the jig set up for internal threading.

This is a close up of the cutter which is supplied in a MT1 arbor which i have secured in a MT1 to MT2 converter sleave to suit the Fox lathe. Also a view of the threads cut internally.

My final picture shows a close up of the two halves screwed together and a further shot of the cutter.

I hope these photographs tell most of the story but to clarify first turn your box or other project and thread the male thread first by mounting the chuck on the jig, visually aligning the threaded shaft with the lathe bed and carefully touching the area to be threaded onto the cutter with the lathe stationary.

Advance the top slide by slacking the clamp screw (Bristol Handle) and knowing the top slide adjusting screw is 1mm pitch advance the adjusting knob by half a turn for the first cut.

Start the lathe ensuring you keep well clear of the rotary thread milling cutter and slowly advance the work onto the cutter and watch the thread appear. Un wind the job back to the beginning with the cutter still running and when clear release the clamp screw and advance the adjustment by a second half turn. This gives full thread depth .

Measure the thread root diameter and open the internal part to be threaded to this diameter. Adjust this piece so that the cutter touches the inside of the box and repeat the procedure for external threading.

After two passes the thread is complete and a light sanding of the thread peaks on both parts will help to stop the threads biding as will a little soft polish.

I do hope that this information has clarified the process.

Regards,

Ian