I got this commision a couple of months ago-

To design and build an Oak drinks cabinet/sideboard.

They have an existing one, which is made in a nasty and tatty, cheap pine, however it is much used and affectionately called 'the Alter' by my clients.

They love Oak furniture, and paticularly like Art's and Crafts style and have a real passion about supporting local crafts and skills (bonus!).

The piece is all solid European Oak, with AB Walnut details. The back and drawer sides are American Red Oak. They have an existing long case clock in Oak and Walnut with a curved door that they are paticularly proud of, this was the biggest influence on the design.

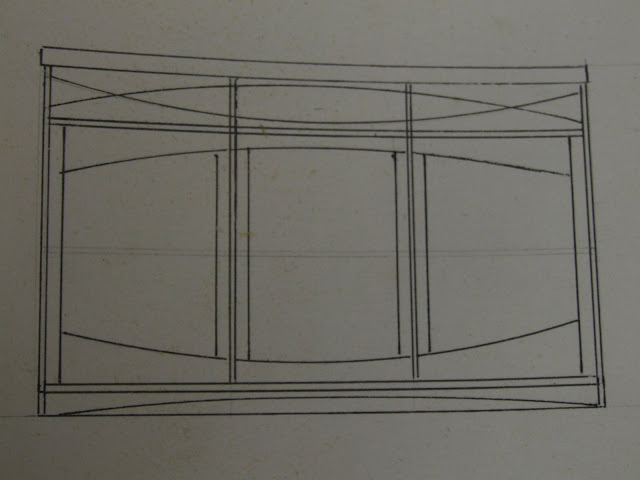

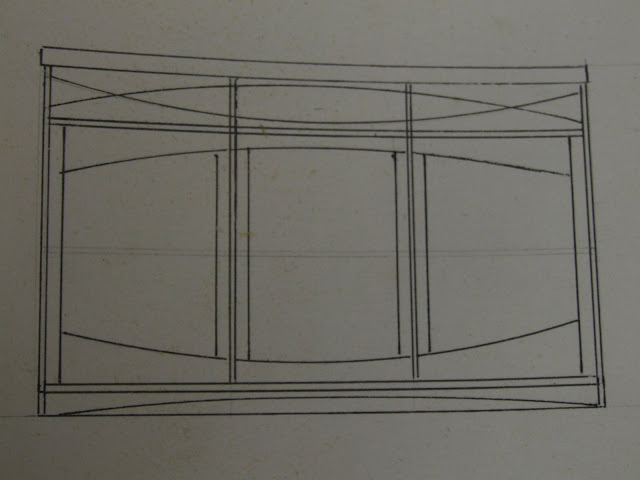

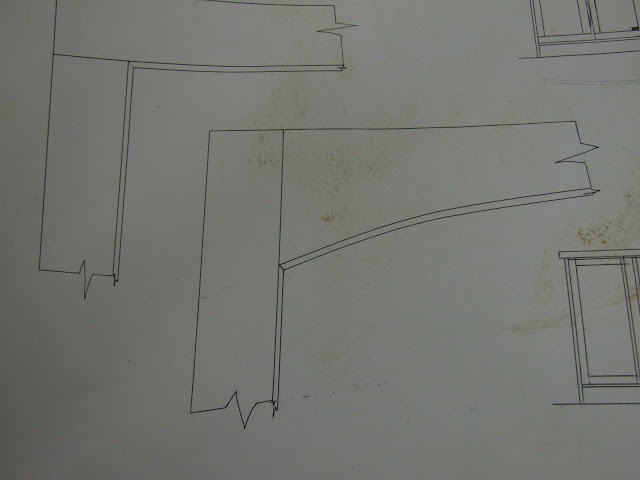

So after a couple of meetings, i finally came up with this as a design-

Sorry about the mucky drawings, they have the originals, these are just my working drawing's.

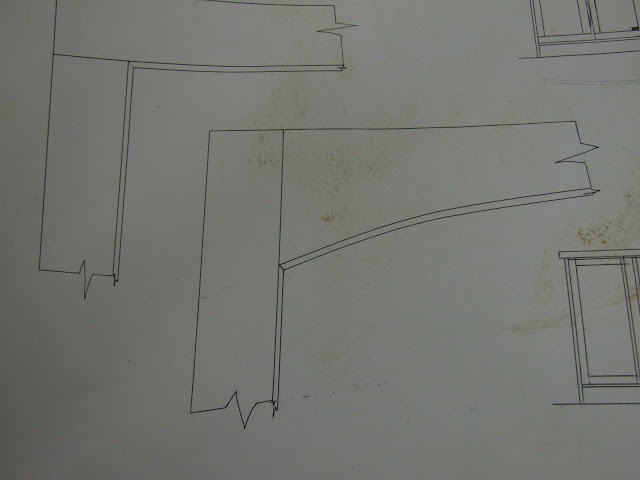

The curved door showing a **** bead detail.

I went and selected the timber myself for this one, I wanted quarter sawn boards throughout and there is no way they would have delivered this.

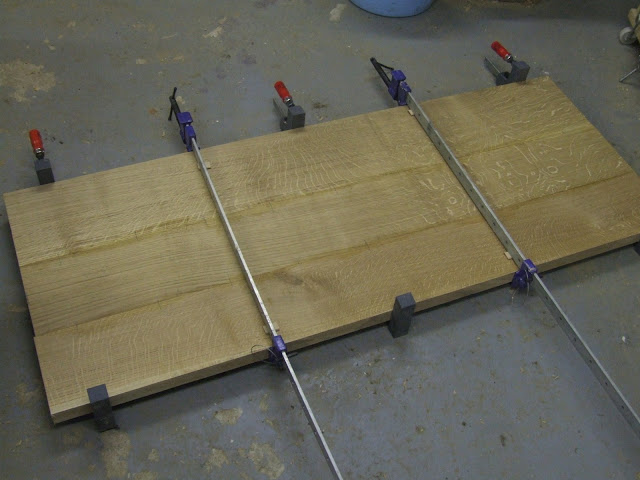

Lots of planing to get some of the bigger glue ups out the way-

Nice quarter sawn

Nice quarter sawn

Yours truly shooting the joints on the top-

The two ends are frame and panel construction- The prepared timber

Any questions or comments- fire away, i'll post more later.

To design and build an Oak drinks cabinet/sideboard.

They have an existing one, which is made in a nasty and tatty, cheap pine, however it is much used and affectionately called 'the Alter' by my clients.

They love Oak furniture, and paticularly like Art's and Crafts style and have a real passion about supporting local crafts and skills (bonus!).

The piece is all solid European Oak, with AB Walnut details. The back and drawer sides are American Red Oak. They have an existing long case clock in Oak and Walnut with a curved door that they are paticularly proud of, this was the biggest influence on the design.

So after a couple of meetings, i finally came up with this as a design-

Sorry about the mucky drawings, they have the originals, these are just my working drawing's.

The curved door showing a **** bead detail.

I went and selected the timber myself for this one, I wanted quarter sawn boards throughout and there is no way they would have delivered this.

Lots of planing to get some of the bigger glue ups out the way-

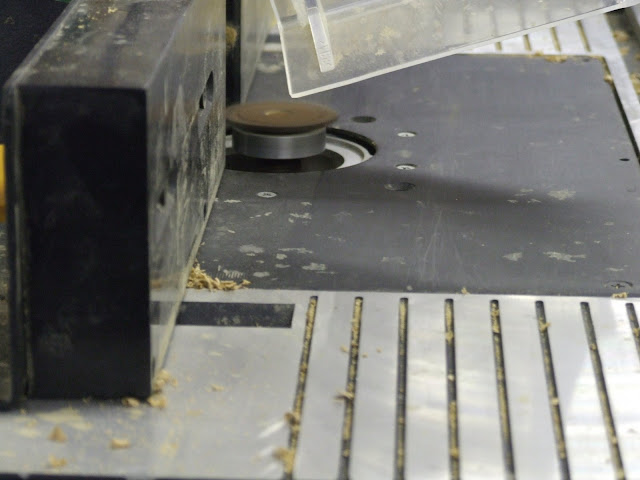

Yours truly shooting the joints on the top-

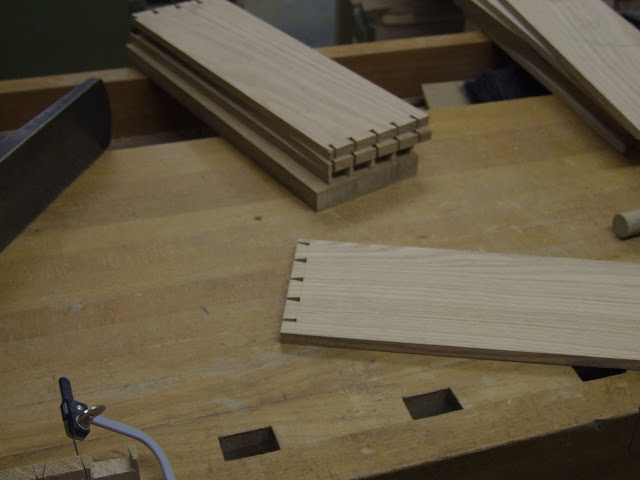

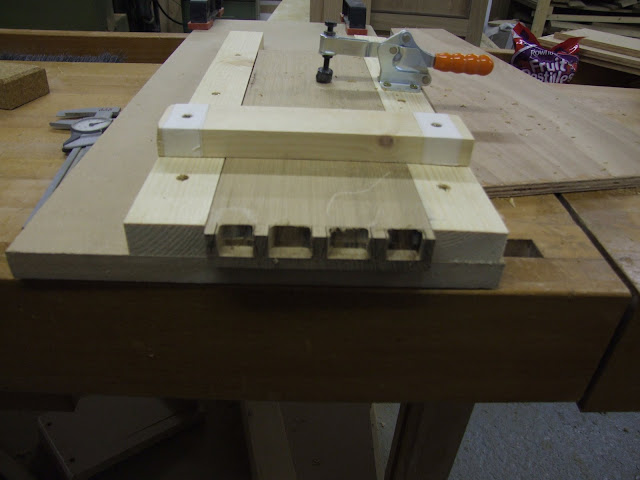

The two ends are frame and panel construction- The prepared timber

Any questions or comments- fire away, i'll post more later.