rich1911

Established Member

I know there are a few threads on this, but just thought I'd ask again for this specific job.

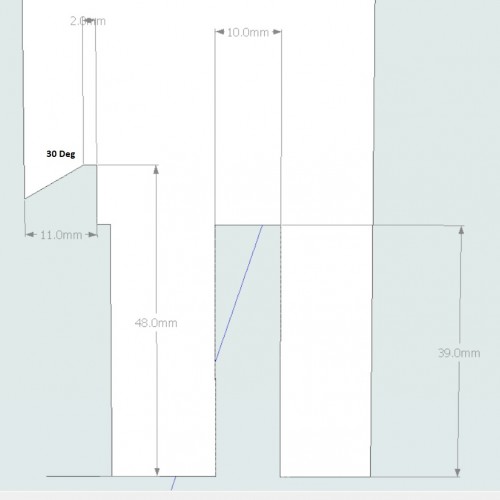

This is the profile I want to cut for a sash rail:

I can cut the 10mm x 39mm slot with my wobble saw. It cuts a pretty clean groove, with a few tiny ridges at the bottom.

For the 30 degree scribed slot, can I fit a tenoning head to the spindle? Do they come with 30mm bores?

Could I take the bulk of the material out with my rebate block and then get some knives made for my 40mm cutter block to take out the remaining bit with the 30 degree bevel on?

I'm using a Felder BF6 with 4kw motors on and a decent sliding table.

I don't minding spending some £££ on tooling but I'd like to try and use as much as I already have (wobble saw, rebate and multi cutter block).

Any thoughts?

Top

This is the profile I want to cut for a sash rail:

I can cut the 10mm x 39mm slot with my wobble saw. It cuts a pretty clean groove, with a few tiny ridges at the bottom.

For the 30 degree scribed slot, can I fit a tenoning head to the spindle? Do they come with 30mm bores?

Could I take the bulk of the material out with my rebate block and then get some knives made for my 40mm cutter block to take out the remaining bit with the 30 degree bevel on?

I'm using a Felder BF6 with 4kw motors on and a decent sliding table.

I don't minding spending some £££ on tooling but I'd like to try and use as much as I already have (wobble saw, rebate and multi cutter block).

Any thoughts?

Top