Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 76

These aren't finished yet, but this thread popped up yesterday, so I thought I might comment...

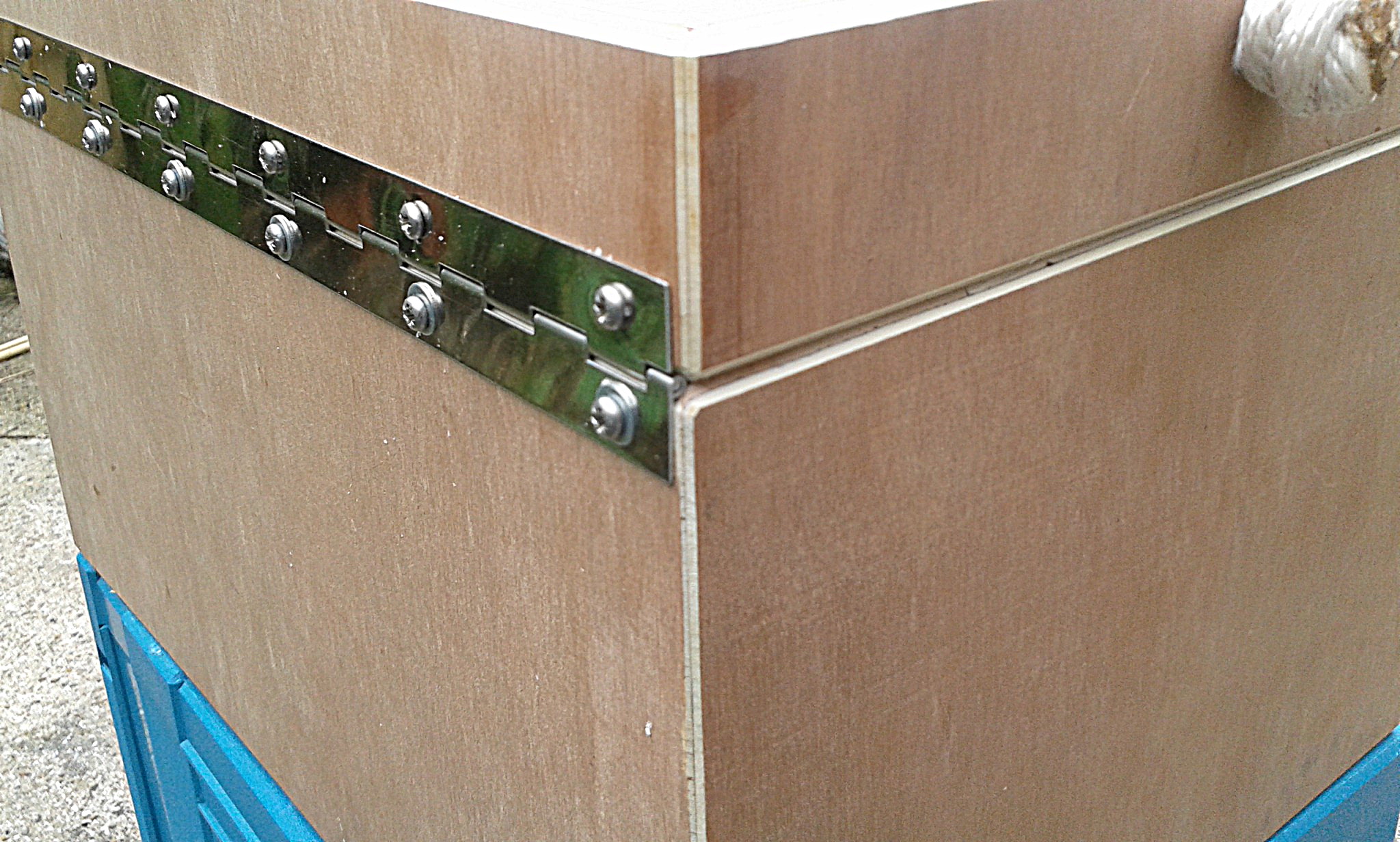

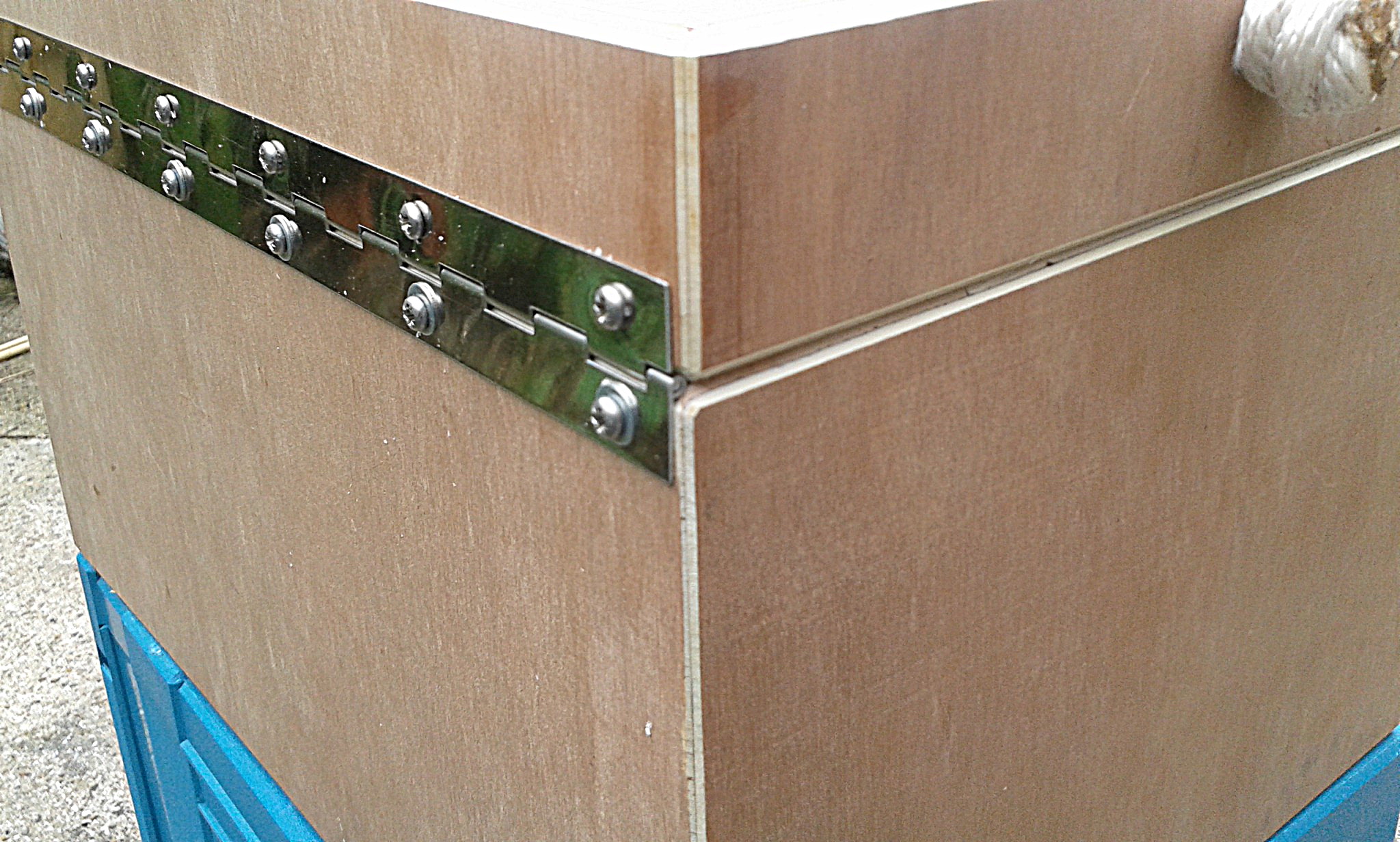

As you can see, they're roughly the same as size 4 Systainers. I decided I wasn't going to mess about trying to copy the Systainer latch system for two reasons: Firstly it wastes too much space inside the container (wooden sides are inevitably much thicker than plastic ones, and even in plastic it's wasteful), and secondly life's just too short. So I came up with a design that has almost no sticky-out bits front and back, but the clips will be on the ends of the boxes. This is so they'll slide into storage end-on and won't get caught on things when being pulled or pushed into place.

For that reason, I've put the piano hinge on "back to front", also so that it jams slightly beyond 90 degrees, acting as a lid stay. So far this is fine, but I may yet fit a lid strap internally to prevent damage. The bevelling on the arrises is for several reasons, but mainly to disguise the fact the lids and boxes don't match as well as they should! My table saw is out of commission at the moment, so they were made separately - not a good way to do it! I was also experimenting with mitre-lock cutters and wanted to see how good the glue-line was. Better than I feared - they'll be perfectly strong enough.

They're made in really, really manky, nominally 12mm ply, with 5mm top and bottom panels. All simply glued and cramped with Titebond II. Even though lumps flew off the tongues during the machining, they seem very strong. The grooves for the dividers were done in two passes to give a slightly loose fit (ply is 5.3mm but the only suitable cutter I have is 5.1mm!), so I can vacuum them out occasionally. The partitions fit my two Makita sanders (belt + orbital), in each case the second compartment holds the abrasives and accessories.

I've temporarily run out of 1/2" #6 screws, so I haven't fitted the other clips yet.

Basically, the height of the lid allows two more clips at each end, right on the corners, clipping the lid under the body of the upper box (hooks on ends of body, clips on ends of lid). I'm sure the whole will be strong enough to lift two of this big size at once.

The feet will glue into the corners, so they locate in the lid trays. The rope handle was an experiment, but seems to be just the job. In use the lid tray also serves as a handy place to park things whilst working.

When I've fitted the other clips and finished the second box I'll amend this with pictures of the clip-together system.

Why "Matthew Walker" boxes? Because the round stopper knot at each end of the handle is known as a Matthew Walker! But you knew that...

E.

https://flic.kr/s/aHskFaDizU

PS: No pop rivets have been abused in the making of these objects (so far, at least!)

As you can see, they're roughly the same as size 4 Systainers. I decided I wasn't going to mess about trying to copy the Systainer latch system for two reasons: Firstly it wastes too much space inside the container (wooden sides are inevitably much thicker than plastic ones, and even in plastic it's wasteful), and secondly life's just too short. So I came up with a design that has almost no sticky-out bits front and back, but the clips will be on the ends of the boxes. This is so they'll slide into storage end-on and won't get caught on things when being pulled or pushed into place.

For that reason, I've put the piano hinge on "back to front", also so that it jams slightly beyond 90 degrees, acting as a lid stay. So far this is fine, but I may yet fit a lid strap internally to prevent damage. The bevelling on the arrises is for several reasons, but mainly to disguise the fact the lids and boxes don't match as well as they should! My table saw is out of commission at the moment, so they were made separately - not a good way to do it! I was also experimenting with mitre-lock cutters and wanted to see how good the glue-line was. Better than I feared - they'll be perfectly strong enough.

They're made in really, really manky, nominally 12mm ply, with 5mm top and bottom panels. All simply glued and cramped with Titebond II. Even though lumps flew off the tongues during the machining, they seem very strong. The grooves for the dividers were done in two passes to give a slightly loose fit (ply is 5.3mm but the only suitable cutter I have is 5.1mm!), so I can vacuum them out occasionally. The partitions fit my two Makita sanders (belt + orbital), in each case the second compartment holds the abrasives and accessories.

I've temporarily run out of 1/2" #6 screws, so I haven't fitted the other clips yet.

Basically, the height of the lid allows two more clips at each end, right on the corners, clipping the lid under the body of the upper box (hooks on ends of body, clips on ends of lid). I'm sure the whole will be strong enough to lift two of this big size at once.

The feet will glue into the corners, so they locate in the lid trays. The rope handle was an experiment, but seems to be just the job. In use the lid tray also serves as a handy place to park things whilst working.

When I've fitted the other clips and finished the second box I'll amend this with pictures of the clip-together system.

Why "Matthew Walker" boxes? Because the round stopper knot at each end of the handle is known as a Matthew Walker! But you knew that...

E.

https://flic.kr/s/aHskFaDizU

PS: No pop rivets have been abused in the making of these objects (so far, at least!)