Jacob":22daq4eb said:Saw-board performs just as well as a track saw once it's set up, depending on the saw itself and given similar dust extraction. They are deceptively accurate.woodbrains":22daq4eb said:..........The system is quicker, more accurate and less fiddly than a saw board by a large margin. .......

But yes is a bit more fiddly, is heavier, not easily adjusted for length, loses its thickness in depth of cut, but saves a lot of money.!! And you can make one up to fit any hand held circ saw or router, at very little cost.

Horses for courses.

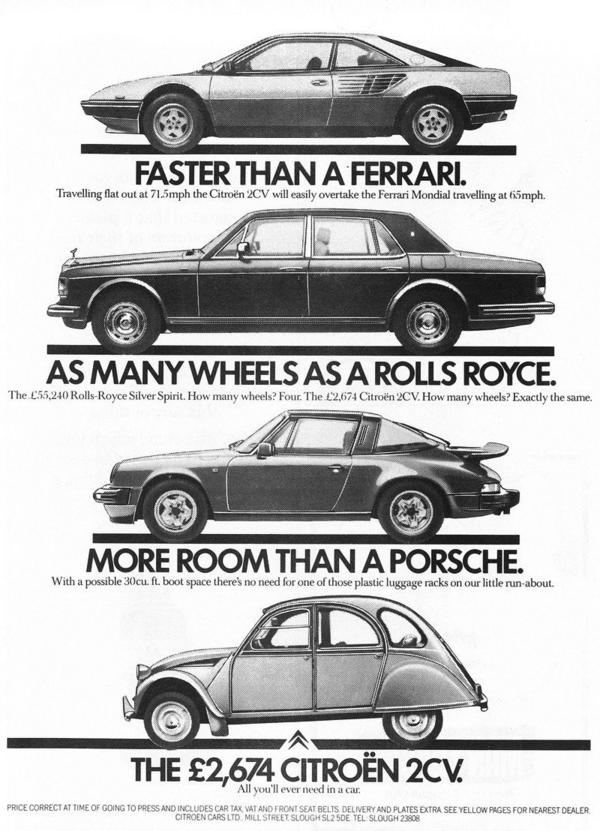

When I was at college one of my lecturers had a 2CV. His standard repost to us tacking the mickey was that a 2CV had as many wheels as a Porsche 911 and at 70mph was just as fast as a Posrche 911 also doing 70mph. All very true but completely avoids the real point that there was no comparison.