OPJ

Established Member

Hi guys,

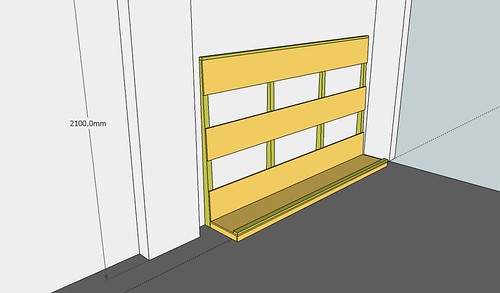

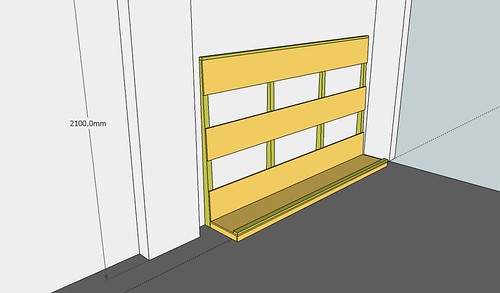

If I can get rid of a couple more items of junk then I should have enough room to build a simple storage area for laying sheet materials horizontally (the walls are only 2100mm). This'll be right next to the up-and-over door, just behind my mitre saw station, which is on 100mm castors.

This is currently what I have in mind:

There's about 2500mm (plenty! 8)) between the end wall and pillar and the length of the "pen" isn't critical (I'll go with the length of my spare OSB sheets). Those studs would be tapered in length; cut from two lengths of 4"x2" and fixed to the wall. I don't want to build it up too tall at the front or it will foul the mitre saw cabinet. Angling them back toward the wall slightly is ideal.

My main priority here is not only to tidy them up but to get them off the damp walls and floor during the winter (I recently had to throw away a good amount of 6mm ply ).

).

What do you think of this idea?

While I can't afford the space for a fancy fold-up unit that provides you with a cutting-bench, are there any other ideas out there that I could consider? I haven't been able to find much, myself.

Above this, I will eventually fit another wood rack (...in addition to the four-or-five elsewhere...!! :wink

:wink

This is how it was looking a few weeks ago, by the way.... :?

(A couple of tools have moved around or been replaced, since then. Regardless; that large mess in the middle remains there today! )

)

Thanks for looking,

Olly.

If I can get rid of a couple more items of junk then I should have enough room to build a simple storage area for laying sheet materials horizontally (the walls are only 2100mm). This'll be right next to the up-and-over door, just behind my mitre saw station, which is on 100mm castors.

This is currently what I have in mind:

There's about 2500mm (plenty! 8)) between the end wall and pillar and the length of the "pen" isn't critical (I'll go with the length of my spare OSB sheets). Those studs would be tapered in length; cut from two lengths of 4"x2" and fixed to the wall. I don't want to build it up too tall at the front or it will foul the mitre saw cabinet. Angling them back toward the wall slightly is ideal.

My main priority here is not only to tidy them up but to get them off the damp walls and floor during the winter (I recently had to throw away a good amount of 6mm ply

What do you think of this idea?

While I can't afford the space for a fancy fold-up unit that provides you with a cutting-bench, are there any other ideas out there that I could consider? I haven't been able to find much, myself.

Above this, I will eventually fit another wood rack (...in addition to the four-or-five elsewhere...!!

This is how it was looking a few weeks ago, by the way.... :?

(A couple of tools have moved around or been replaced, since then. Regardless; that large mess in the middle remains there today!

Thanks for looking,

Olly.