motownmartin

Established Member

Every year we have the same problem, the cushions for the outdoor furniture end up scattered around the sun lounge when it rains, the thing is that it's nice to sit in the sun lounge when you can't sit outside but there are no seats to be found, as the first pic shows

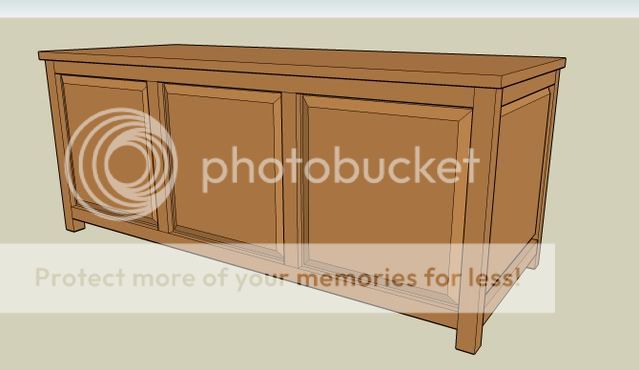

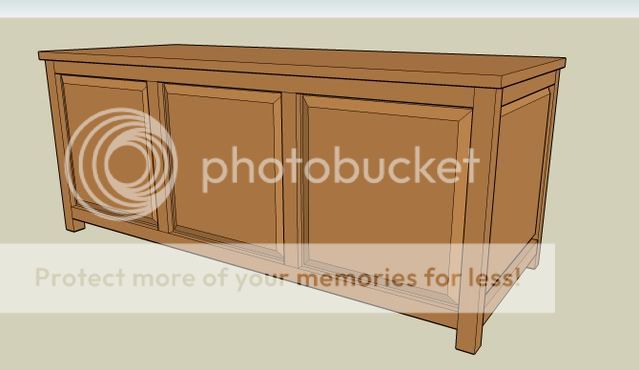

So I thought about making a storage chest, like this

The dimensions of this are 5 feet by 2 feet by 2 feet, does anyone see any problems making a large chest like this out of Oak (apart from the cost)

So I thought about making a storage chest, like this

The dimensions of this are 5 feet by 2 feet by 2 feet, does anyone see any problems making a large chest like this out of Oak (apart from the cost)