Derek Cohen (Perth Oz)

Established Member

During my recent build of the kist I was sawing mouldings on a Millers Falls Acme 74A, and realised that it was similar to cracking nuts with a sledgehammer. I would kill for a small version of this mitrebox, but they are rare as rocking horse droppings and twice as expensive.

I usually build a tool between furniture projects and, consequently, decided this one would be my own version of a small MF .... well, sort of ...

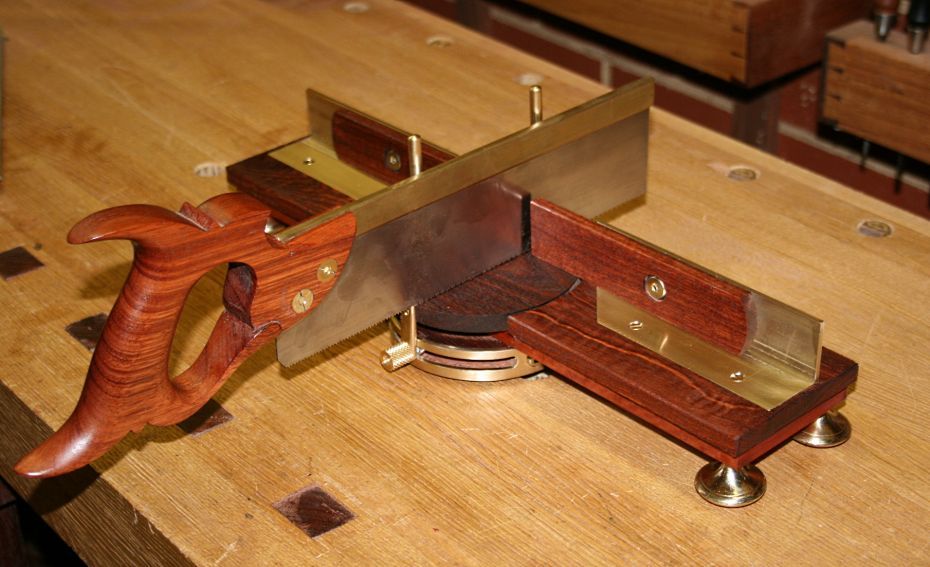

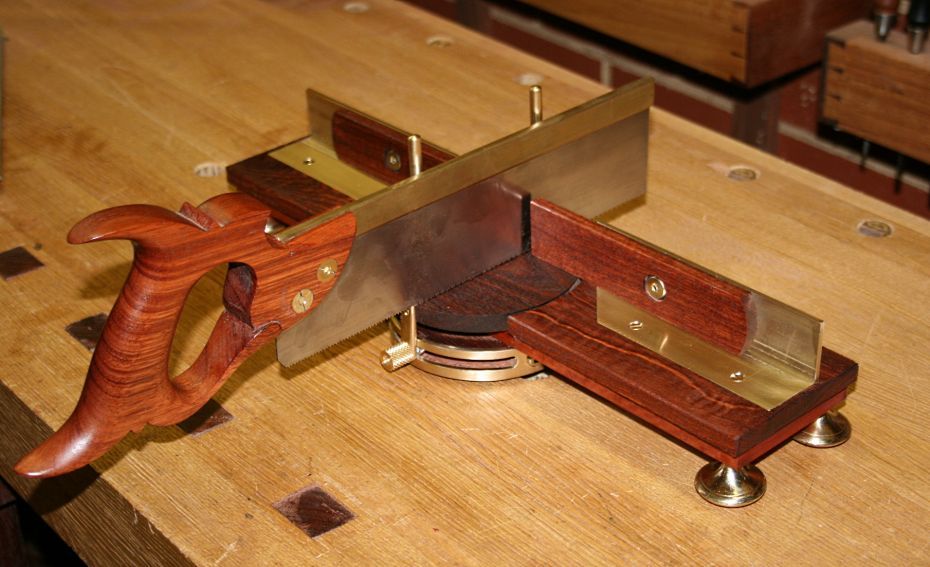

The mitrebox is Jarrah and brass, just under 17" in length, 4" deep, and 3 1/4" to the top of the fences. It is used with an 11" carcase saw I made 2 years ago. This has a 2 1/4" plate and is filed 14 ppi crosscut.

In order to make the depth as shallow as possible, the turntable (for the saw) needed to be small, and this led to placing it pivot point in the centre of the bed. To close up the gap in the fence that results from this, the fence contains a subfence that slides back-and-forth ...

With the fences back, the mitrebox is optimised for mitres ...

Here is the same moulding from the kist ....

A comparison with a MF Acme 74A ...

The heart of the saw-holding mechanism is a plate with rare earth magnets ...

Another shot, as well as the angle locking mechanism ...

The locking mechanism is built on a morticed Jarrah disk ...

The fence is a 1 1/4" x 1 1/4" brass angle section, with Jarrah subfences. At the rear is a slide adjuster ...

You can make out the angle settings. The fence is set up for quick adjustment to 45 degrees either way and 90 degrees. It has a variable range from about 40 degrees. The saw can be used on either side of the fence.

Here is a close up of the settings ...

Regards from Perth

Derek

I usually build a tool between furniture projects and, consequently, decided this one would be my own version of a small MF .... well, sort of ...

The mitrebox is Jarrah and brass, just under 17" in length, 4" deep, and 3 1/4" to the top of the fences. It is used with an 11" carcase saw I made 2 years ago. This has a 2 1/4" plate and is filed 14 ppi crosscut.

In order to make the depth as shallow as possible, the turntable (for the saw) needed to be small, and this led to placing it pivot point in the centre of the bed. To close up the gap in the fence that results from this, the fence contains a subfence that slides back-and-forth ...

With the fences back, the mitrebox is optimised for mitres ...

Here is the same moulding from the kist ....

A comparison with a MF Acme 74A ...

The heart of the saw-holding mechanism is a plate with rare earth magnets ...

Another shot, as well as the angle locking mechanism ...

The locking mechanism is built on a morticed Jarrah disk ...

The fence is a 1 1/4" x 1 1/4" brass angle section, with Jarrah subfences. At the rear is a slide adjuster ...

You can make out the angle settings. The fence is set up for quick adjustment to 45 degrees either way and 90 degrees. It has a variable range from about 40 degrees. The saw can be used on either side of the fence.

Here is a close up of the settings ...

Regards from Perth

Derek