MikeG.

Established Member

Hornbeam":5omyew1e said:.......(google curved glulam beams images.........

:lol: :lol: :lol:

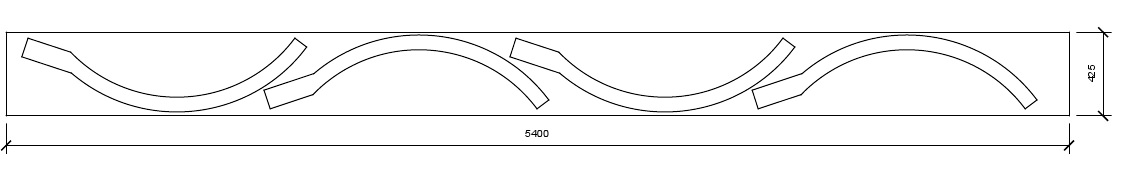

I'm an architect. Here's a house I designed a while back, still going through planning. It's all glulam beams. It will be the first example of glulams curving in 3 dimensions in domestic architecture in Britain if it gets built:

https://imgur.com/SooygYB