devonwoody

Established Member

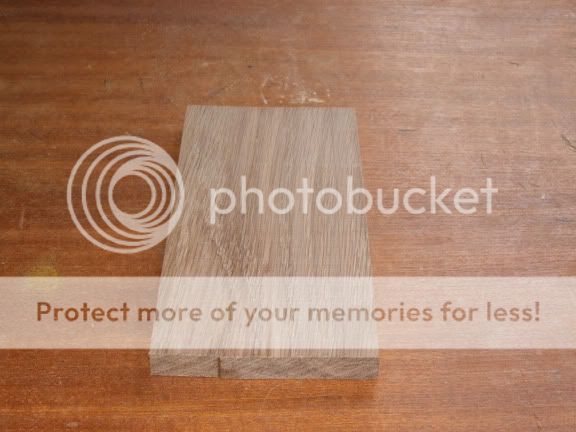

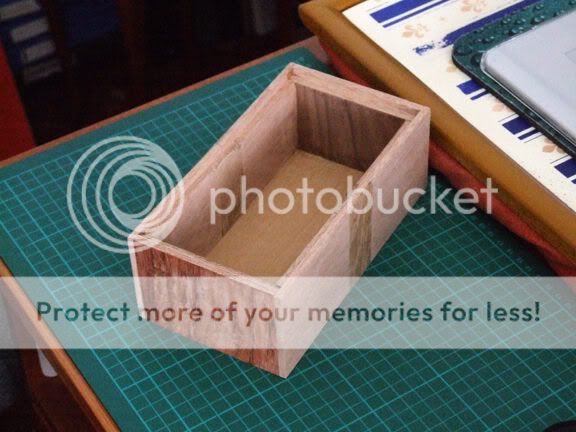

A tiddler this time 8x4x3&5/8ths in some oak that was laying around and could only use some small pieces owing to many shakes and knots but at 25p a lump cannot complain.

Will most probably combine that 6 sided box on this thread as well because I have an idea that might rescue the project.

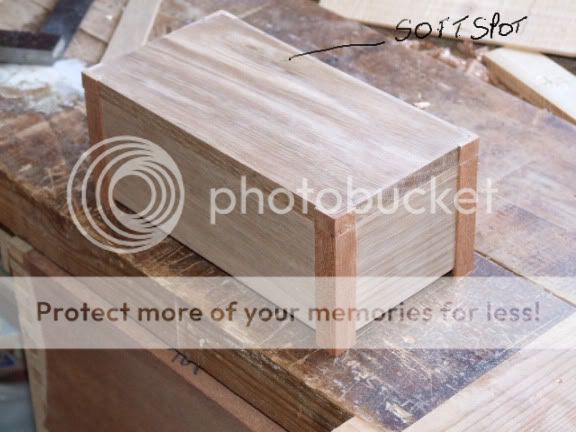

Oak box 4 pieces prepared and handmade dovetails started.

.

Will most probably combine that 6 sided box on this thread as well because I have an idea that might rescue the project.

Oak box 4 pieces prepared and handmade dovetails started.

.