bugbear

Established Member

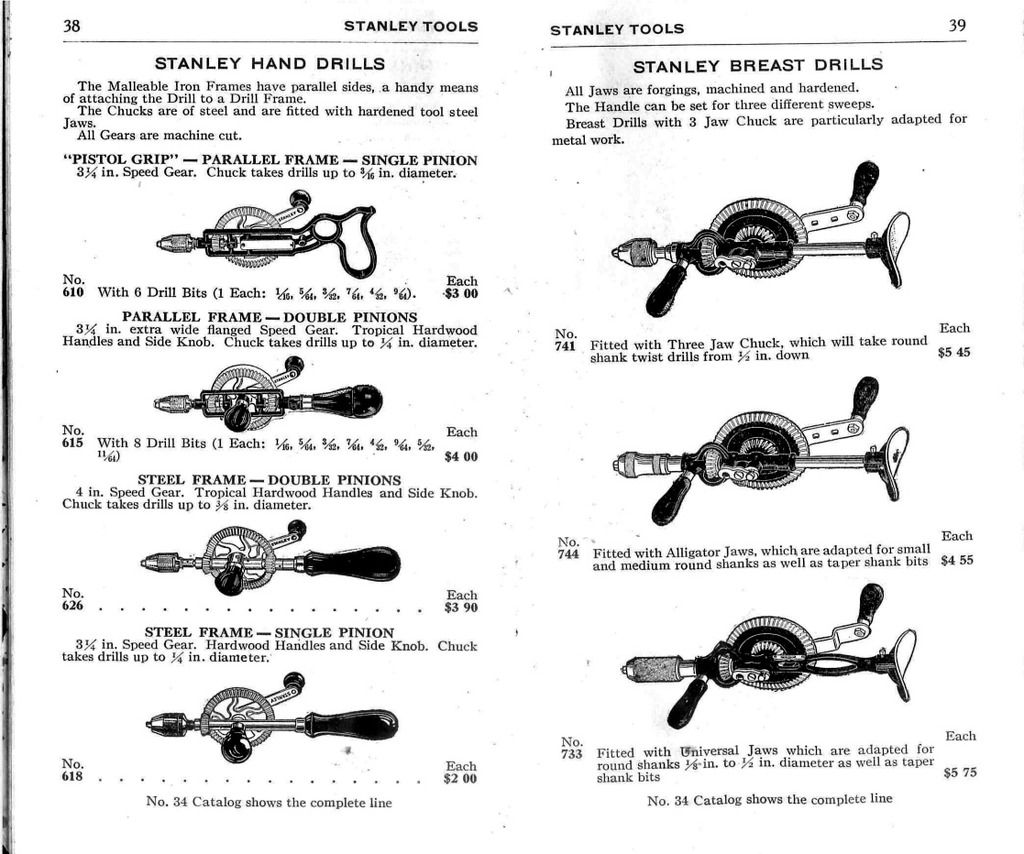

AndyT":27oiwvwr said:bugbear":27oiwvwr said:Does anyone know what the side handle on a hand drill (AKA egg beater) is for?

Being equipped with the usual two hands, I've never found a use for it. :lol:

BugBear

Well, I'm sure I've used it, and maybe even missed having it on drills without one... it's just an alternative way of holding it, which sometimes makes sense. There could even be circumstances where you would remove the big handle and just use the side one - maybe drilling a hole for a handle, from the inside of a small drawer - you do always do that from the inside don't you? Or you might, if you wanted a larger hole on the back to hide a nut? I'm clutching at straws here, but they are really important!!

(Unless it's just a ruse to make another price point... :wink: )

Is the big (inline) handle removeable? I didn't think it was.

For close work I have a Leytool drill - doesn't everybody?

leytool-drill-t84644.html

BugBear (at work, can't check his #803)