I'd just buy "standard bore" tooling with either a 1-1/4in (British standard) or 30mm (Euro standard) bore and then mount on top hats. As you're in Manchester would you like me to pop over and show you a bit about spindle tooling? (PS I'm not a tooling salesman)lBrad Naylor":3w580uec said:By the way, the spindle on my moulder is 1" dia. Is this going to be a problem for me or do I just use those top hat thingies?

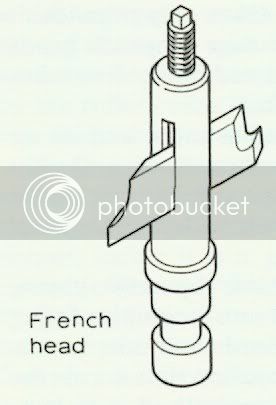

Flat cutters which pass through a slot in the middle of the spindle and which were secured by a nut and bolt at the top, like this:andys wood shed":3w580uec said:Hi Scrit what are french cutters?

I used to rather like them as they work rather like a scratch stock and it was dead easy to grind-up a cutter for a small one off job (which made doing a cutter to make a single 10ft piece of mulding feasible). The downsides are that they are not limiter tooling in any way, they sometimes used to get ejected from the spindle and they could break without warning if you fed in too fiercely. They've been illegal for many years now.

Yep. That's as good a technique as any I knowandys wood shed":3w580uec said:Also how do you sharpen cutter knives. I usually rub them flat on a diamond stone is this correct?

I know Tormek produce a jig anyone used one?

And as for the Stephenson book it's a first rate publication which I'd thoroughly recommend myself. Another useful book is F. E. Sherlock's "Machine Woodworking Technology for Hand Woodworkers" (Stobart-Davis ISBN 0-85442-041-X) which contains information on proper usage of all of the main machines in the workshop

Scrit