Right, you buggers have lured me into your strange cult  I've been reading this forum for a few months and I went from none to one plane quite easily and quickly. Then, the other day, whilst buying some proper kit (for turning), I ended up buying a couple of number 5s and another number 4. So I've now played with sharpening one of each at 20 and 25 degrees and have planed a large block of sapele for no reason other than I wanted to try them out. The next thing I know, I'm searching the bay, Preloved and Gumtree for try planes and spending hours looking at Axminster LN ****...what have you done to me???

I've been reading this forum for a few months and I went from none to one plane quite easily and quickly. Then, the other day, whilst buying some proper kit (for turning), I ended up buying a couple of number 5s and another number 4. So I've now played with sharpening one of each at 20 and 25 degrees and have planed a large block of sapele for no reason other than I wanted to try them out. The next thing I know, I'm searching the bay, Preloved and Gumtree for try planes and spending hours looking at Axminster LN ****...what have you done to me???

Tonight, I drove half an hour to pick up what might be a bargain 21" wooden plane (£12), and which looks flat and in decent condition (not that I really know). I'll put some piccies below so you can tell me what to do next. Please make it quick so that I can get back to my lathe

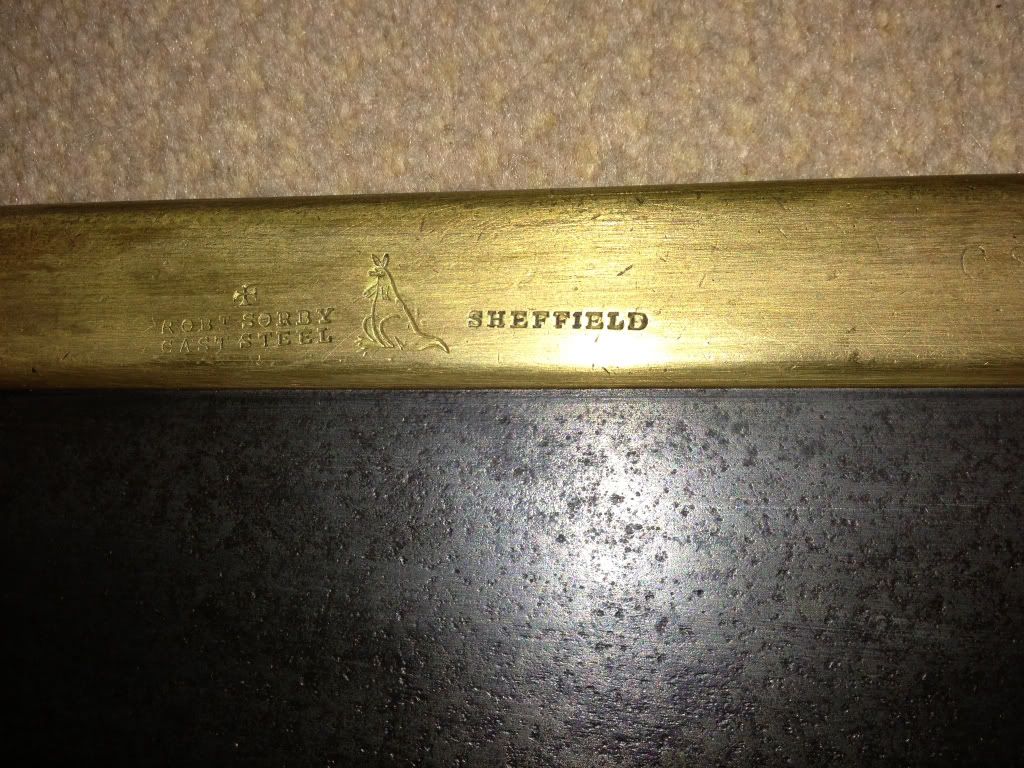

I can't see any maker's marks on the plane, but the iron and the chip-breaker are both marked Ward.

It's a heavy beast.

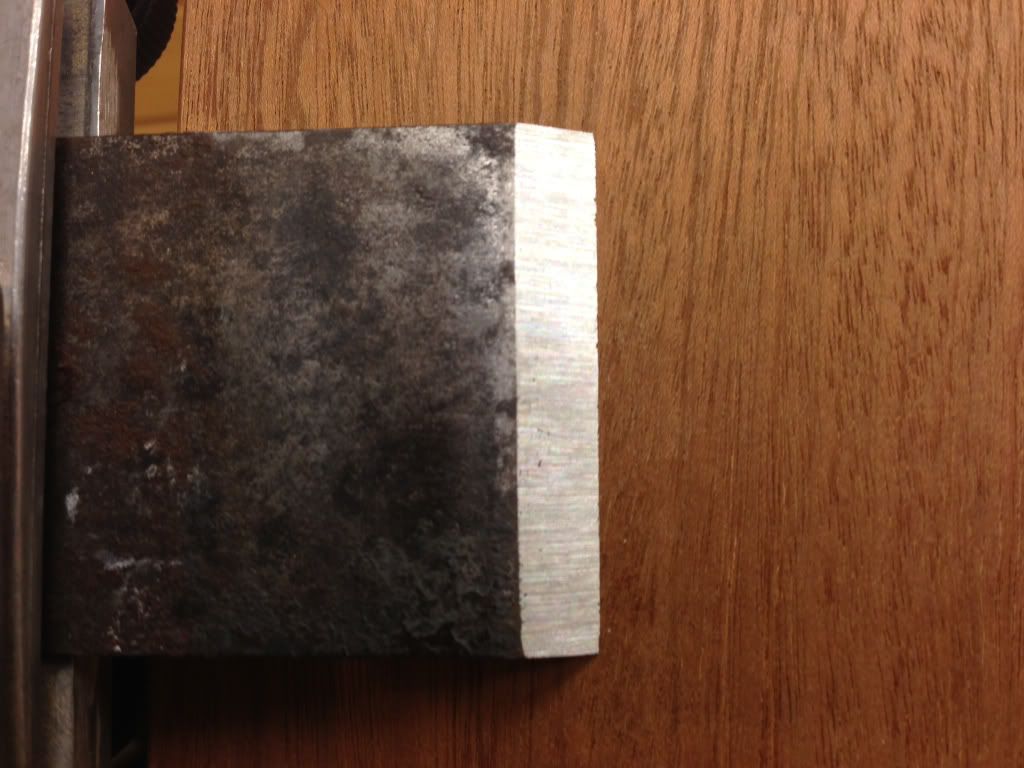

A bit of damage to the ends.

Finally, a freebie...

Seven planes I now own...thanks a lot!

Lovely bloke who sold it to me, very interesting (former turner you see), I could have stayed all night.

Tonight, I drove half an hour to pick up what might be a bargain 21" wooden plane (£12), and which looks flat and in decent condition (not that I really know). I'll put some piccies below so you can tell me what to do next. Please make it quick so that I can get back to my lathe

I can't see any maker's marks on the plane, but the iron and the chip-breaker are both marked Ward.

It's a heavy beast.

A bit of damage to the ends.

Finally, a freebie...

Seven planes I now own...thanks a lot!

Lovely bloke who sold it to me, very interesting (former turner you see), I could have stayed all night.