We'll today I eventually managed to lump it all round to the workshop on my own. I spent a bit of time with a brush and the vacuum to get the remnants of sawdust off and started to take stock of what I had.

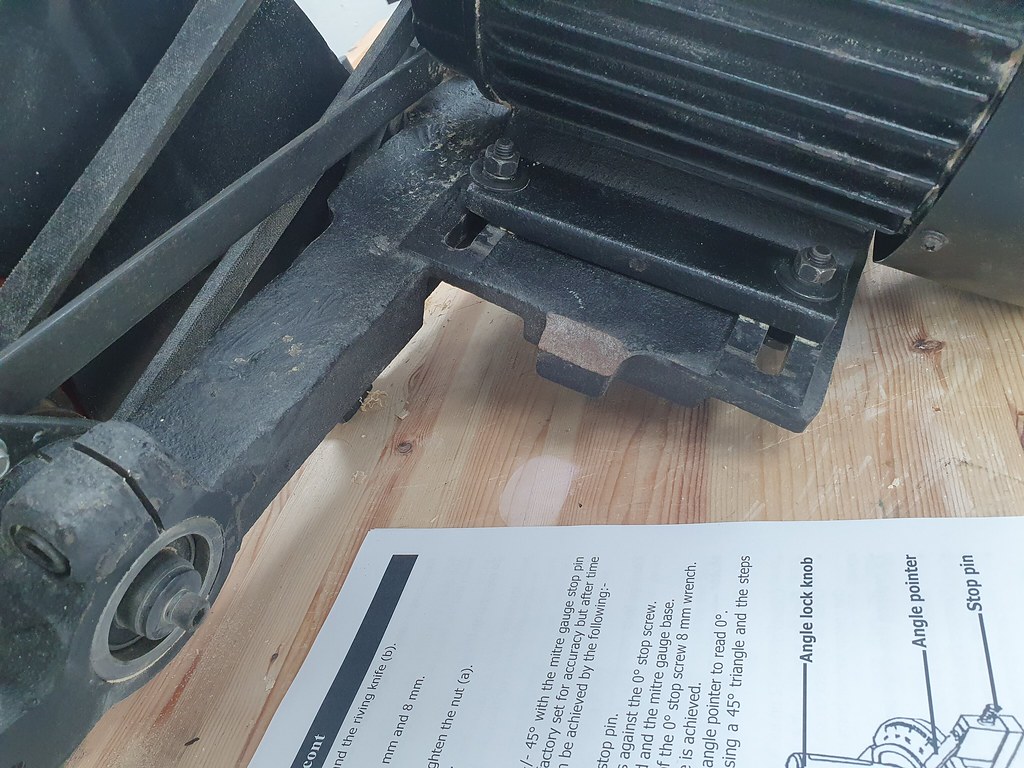

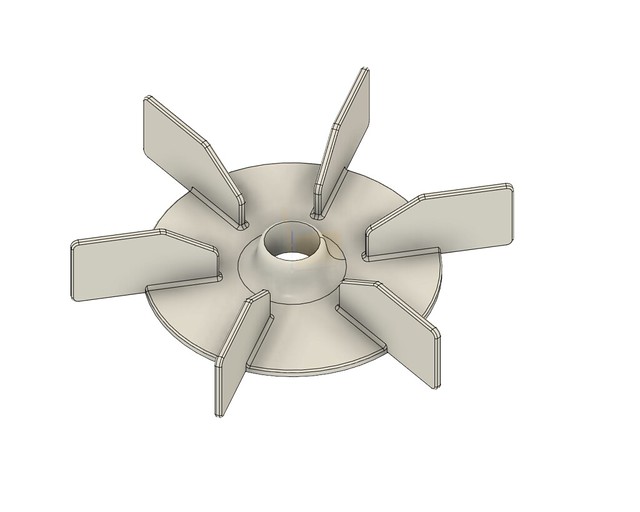

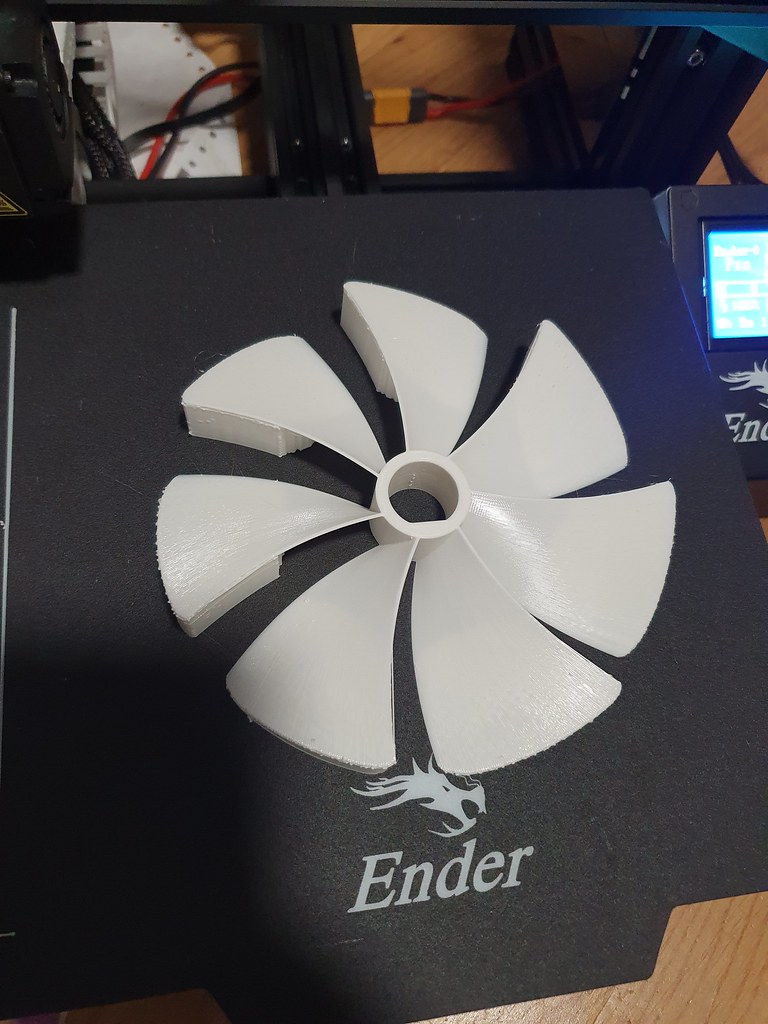

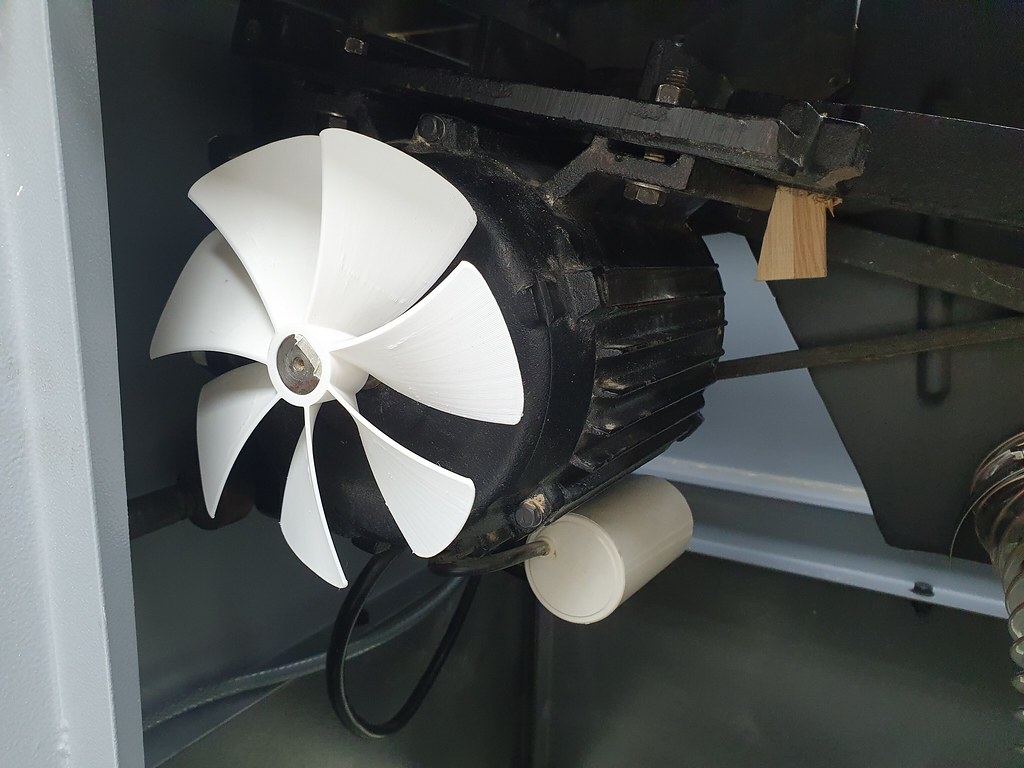

I know when we unhooked everything that there was a bolt missing for the motor where it mounts to the mount, and on subsequent poking around I've found that the tension screw and casting have broken off of the mount, the motor fan seems to have been replaced and is wonky and one of the locking holes on the arbour pulley is broken out, but still useable. The micro adjust on the fence is also missing. I'm not overly worried about any of those. The tensioning bolt looked like a weak point on the design and should be easy enough to remedy (or buy a whole new mount for £80), the fan is a small amount of weight to be off balance, and the other hole in the pulley thing is fine I also can't see a part number for it to buy a replacment anyway.

The riving knife has been filed down so now can't take a guard (which I don't have) and the flange that holds the knife in place is also missing. The flange and a new knife can be bought as spares easily enough.

I did take the liberty of weighing a few bits. I can't recall all of the weights off the top of my head bar the main table. On its own it weighs 50kg exactly. I think the motor alone was about 30 but I'll double check. I'm sure most don't care, but it's of interest to me and maybe it'll help someone before they go dismantling one and having a heavier than expected part pin them to the floor!

At work now for a few days but I can get on with it again next week and get a few spares ordered like the riving knife, riving knife securing plate, new belt. The sipuk site lists the motor replacement at £150,000 so I'm guessing they don't sell many of those. Not perfect to have a few bits missing but this is at least a 3rd hand saw now and it ended up only actually costing me £700. They are £1750 at a minimum new now.

Some pics in the meantime.

Parts all over the shop

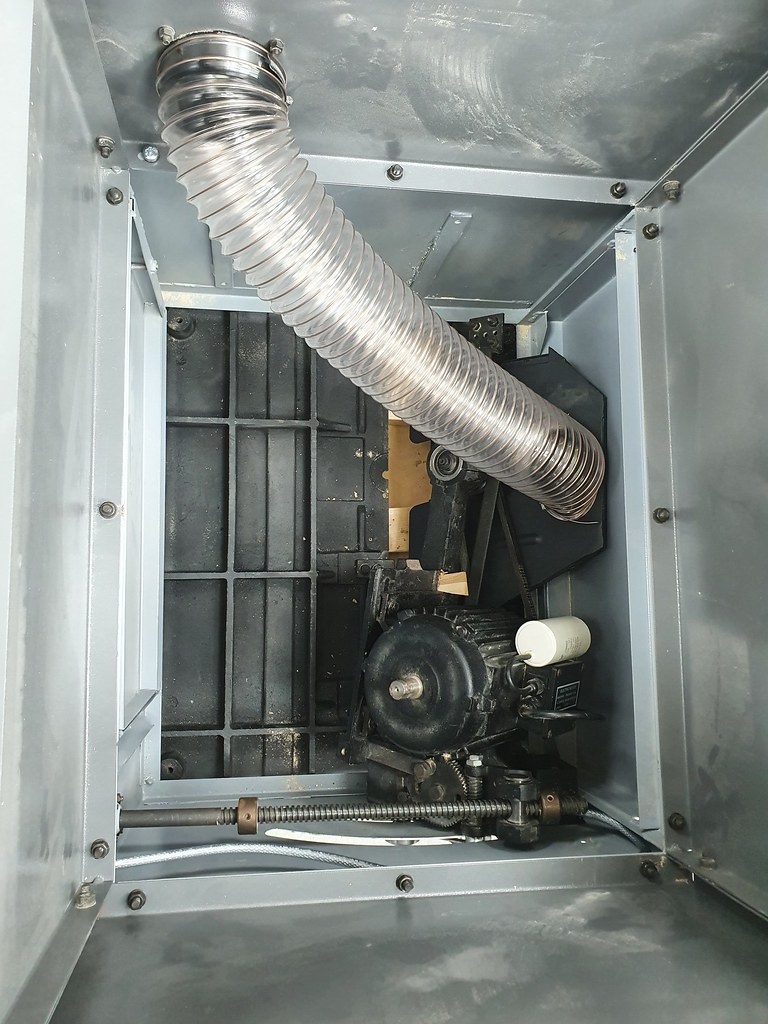

Motor, mount and blade

A 50kg main cast iron top

rails, odds and sods

All the nuts and bolts from the initial dismantling

Broken off tension screw area. You can see the mark on the motor base where the screw would have acted, easy to see why that part has broken from the mount

Goopy fan that looks like it might have been added to replace the original?

Busted out arbour lock hole on the pulley. No idea why they used this design, maybe its common on saws like this?