katellwood

Established Member

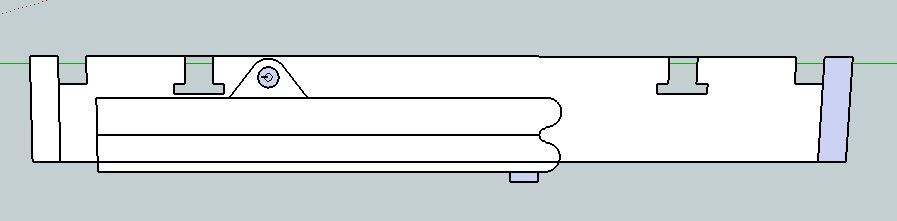

I just managed to get this completed on Christmas eve (well I say completed just two ragged on coats of Osmo)

I fully appreciate I should have done a WIP however I get so engrossed I always forget to take pictures during construction

Its now had five coats of Osmo however I did get a bit of blooming where a warm dish was placed on the tablecloth during Christmas Dinner (how heatproof is Osmo) but cutback with a piece of 320 grit and another coat has cured it

Questions, comments, criticism’s or just your thoughts (anything to help me improve on the next project) are fully welcome

By the way it weighs a ton so won’t be moving it very far and the ability to bring it in through French windows is an absolute bonus

Thanks in anticipation (excuse the photo’s I’m going to be taking lessons)

I fully appreciate I should have done a WIP however I get so engrossed I always forget to take pictures during construction

Its now had five coats of Osmo however I did get a bit of blooming where a warm dish was placed on the tablecloth during Christmas Dinner (how heatproof is Osmo) but cutback with a piece of 320 grit and another coat has cured it

Questions, comments, criticism’s or just your thoughts (anything to help me improve on the next project) are fully welcome

By the way it weighs a ton so won’t be moving it very far and the ability to bring it in through French windows is an absolute bonus

Thanks in anticipation (excuse the photo’s I’m going to be taking lessons)