John. B

Established Member

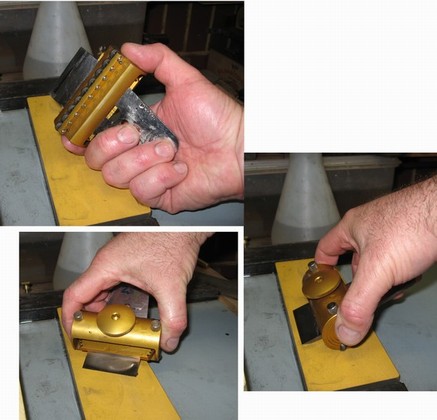

For those who own, or thinking of getting Japanese chisels.

I can recommend this honing guide.

I've had one these Richard Kell honing guides for well over a year with no sign of wear.

I might add, for those who never used Japanese chisels. Their blades are far shorter than western blades,

and other than honing by hand only, finding a guide to fit is very difficult, if not impossible.

The one I have will take chisels or any blade from 0 to 2.5/8"(2" and five eighths)

he does other guides

I'll also add I've nothing to do with Mr Kell I just think this is probably the best guide I've ever owned, and I think you ought to know about him.

John. B

I can recommend this honing guide.

I've had one these Richard Kell honing guides for well over a year with no sign of wear.

I might add, for those who never used Japanese chisels. Their blades are far shorter than western blades,

and other than honing by hand only, finding a guide to fit is very difficult, if not impossible.

The one I have will take chisels or any blade from 0 to 2.5/8"(2" and five eighths)

he does other guides

I'll also add I've nothing to do with Mr Kell I just think this is probably the best guide I've ever owned, and I think you ought to know about him.

John. B