chaoticbob

Established Member

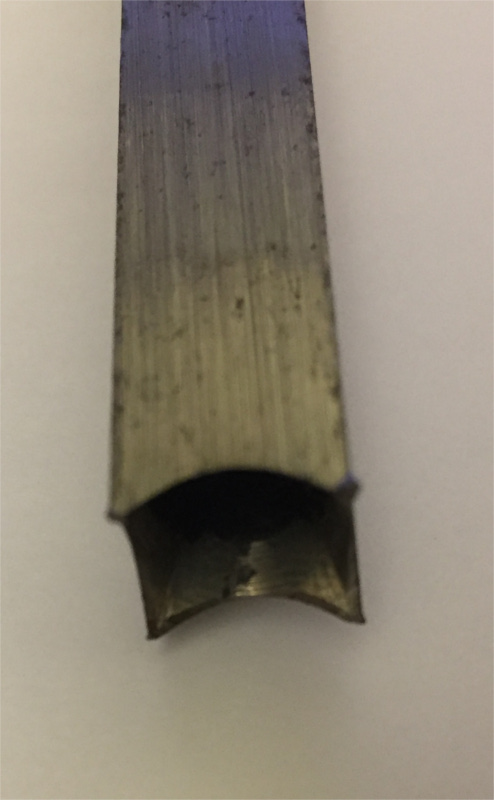

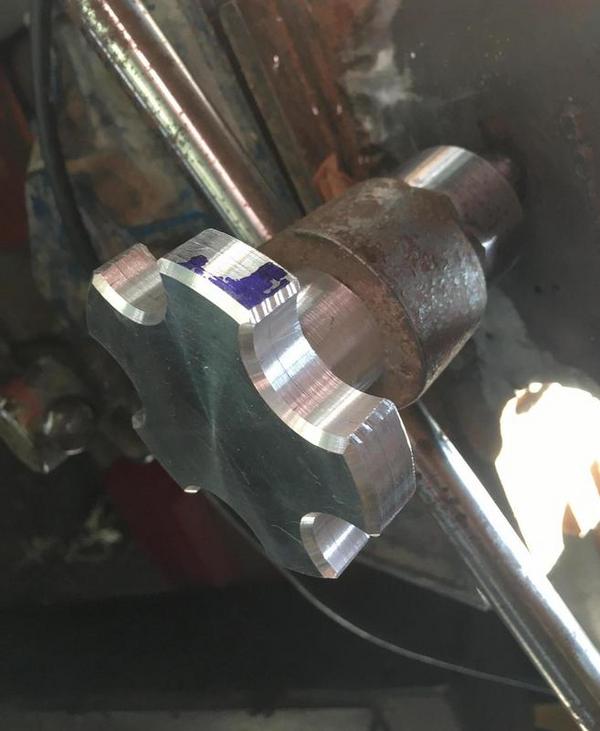

I need to sharpen some second-hand hollow mortice chisels. I've had a look, and there seem to be two types of tool on offer to do the internal bevel - diamond encrusted cones and things which look like countersinks with a pilot. Some say 'suitable for most Taiwanese chisels'. Mine are old British things (marked Wm Ridgway Sheffield).

I had a look at a video from Fine Woodworking demonstrating the diamond cones, but no mention of the provenance of the chisels - from what I could see, there was no secondary bevel on the chisels the guy was sharpening, and no mention of angles. The Ridgway chisels certainly have primary and secondary bevels.

So I'm confused! Any enlightenment would be welcome - especially as to angles. Maybe it's the same as with flat chisels, but I just don't know.

Hoping the forum software doesn't immediately blackball me for using the S-word in the subject line...

Bob.

I had a look at a video from Fine Woodworking demonstrating the diamond cones, but no mention of the provenance of the chisels - from what I could see, there was no secondary bevel on the chisels the guy was sharpening, and no mention of angles. The Ridgway chisels certainly have primary and secondary bevels.

So I'm confused! Any enlightenment would be welcome - especially as to angles. Maybe it's the same as with flat chisels, but I just don't know.

Hoping the forum software doesn't immediately blackball me for using the S-word in the subject line...

Bob.