ScaredyCat

Established Member

I'm have some trouble with my segment jig that I made today and, I think, I've boiled my brain trying to bug fix it.

I was actually getting better results when I just screwed a bit of wood at 15 degrees to my cross cut sled :/

Same sled everyone knows about.

Results I'm getting

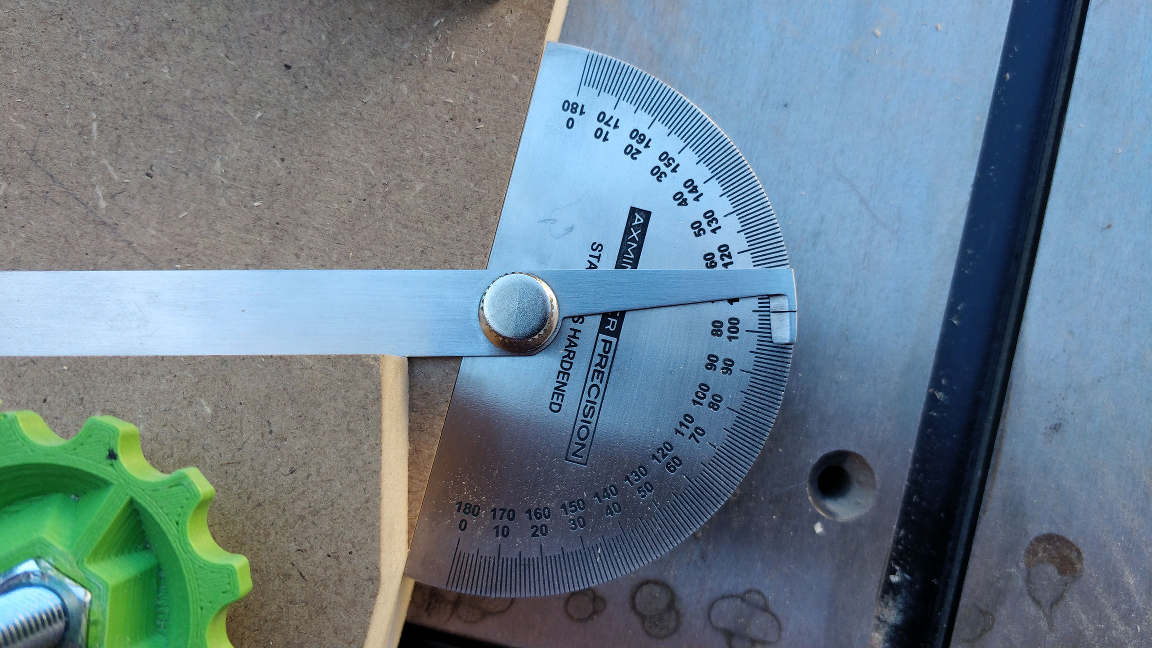

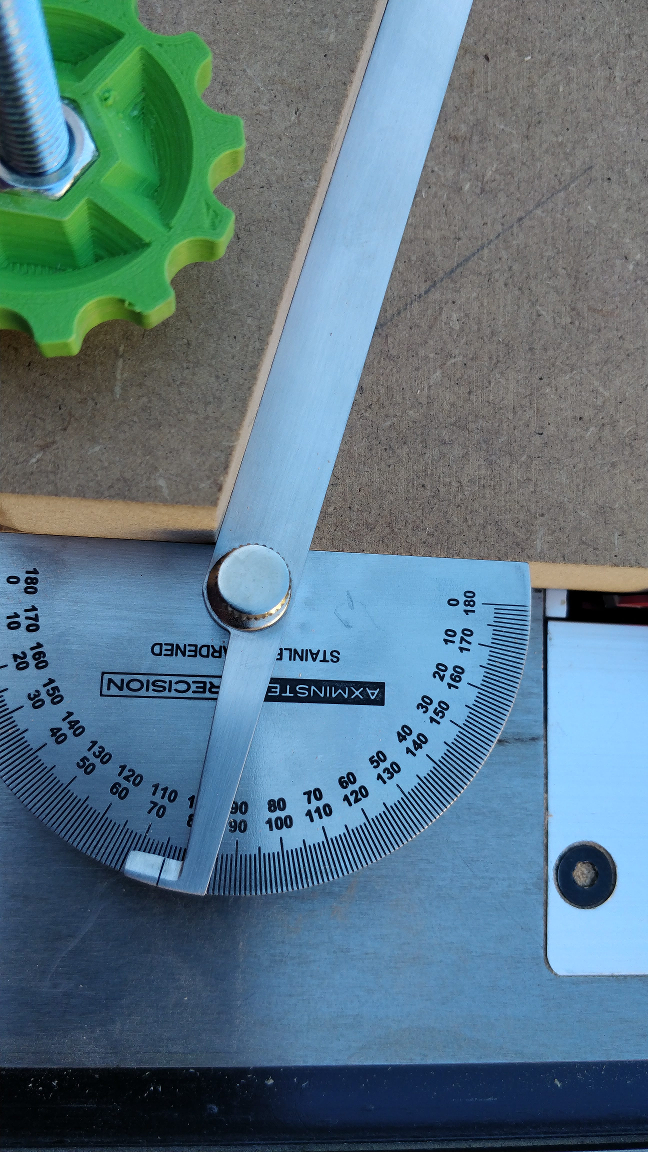

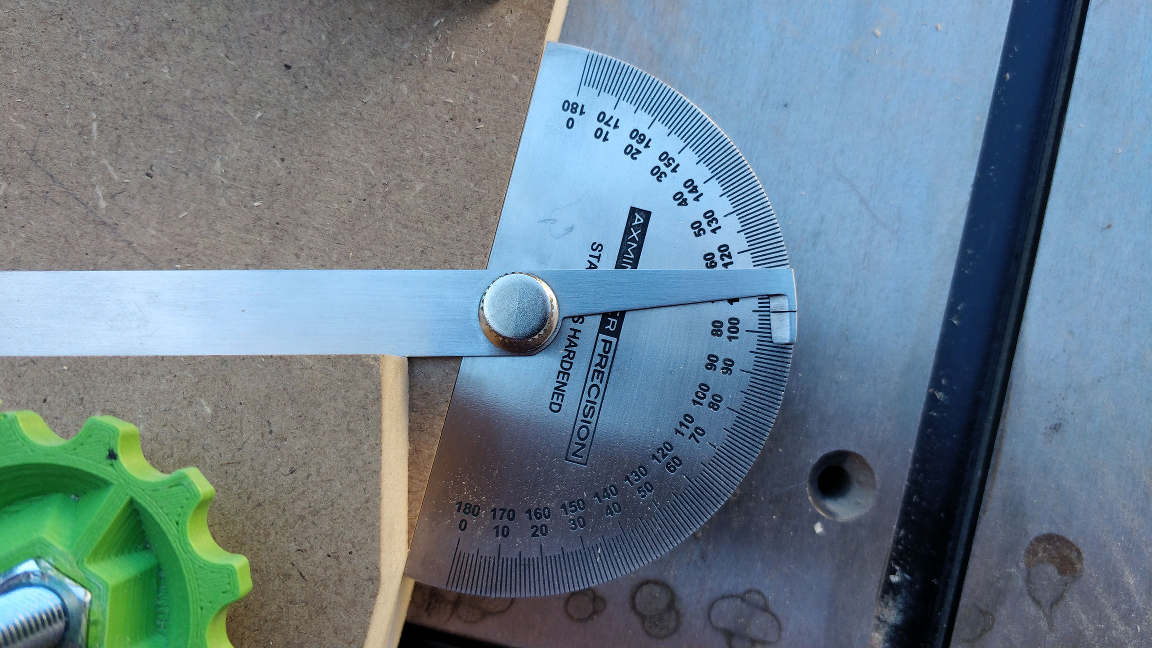

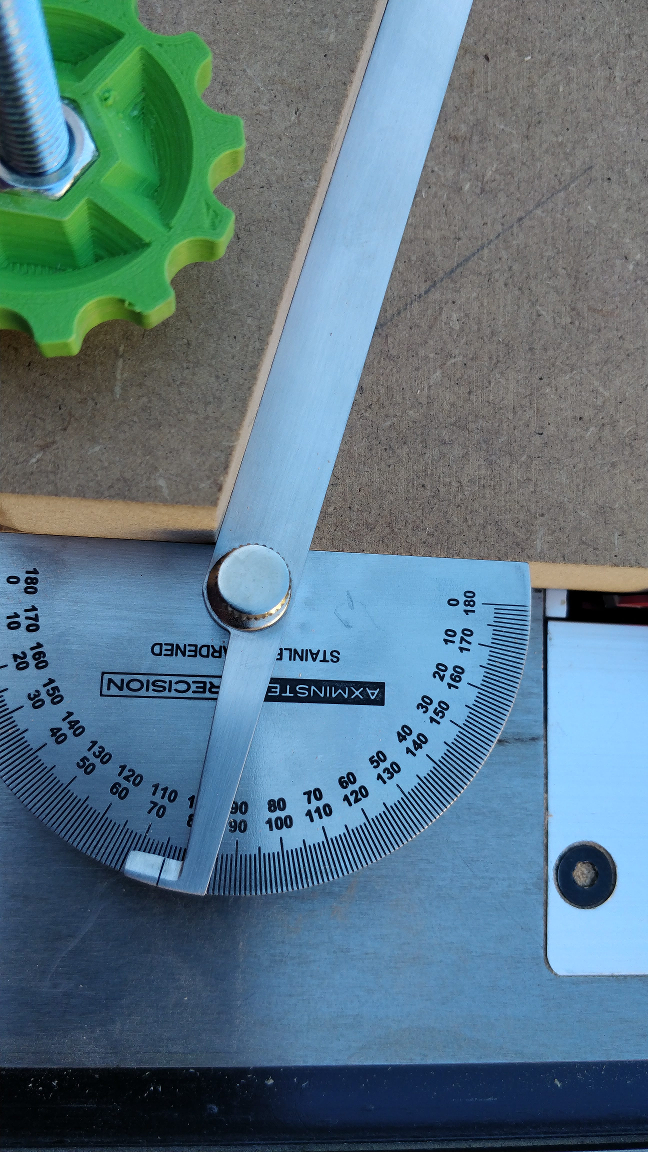

Checking both fences are 15 degrees.

So what now? I can't think of what I've done wrong so I can't think of the fix. Can anyone shed any light on this?

.

I was actually getting better results when I just screwed a bit of wood at 15 degrees to my cross cut sled :/

Same sled everyone knows about.

Results I'm getting

Checking both fences are 15 degrees.

So what now? I can't think of what I've done wrong so I can't think of the fix. Can anyone shed any light on this?

.