carlb40

Established Member

Just for Danny :lol:

Further to this thread.

dovetail-saw-restoration-wip-t76516.html

A saw vice/ chop is needed, so while awaiting drill bits i thought i would knock one up.

It is sort of based on what is called/ referred to as the Lie Nielsen saw vice.

So using scraps of ply and pine i started it.

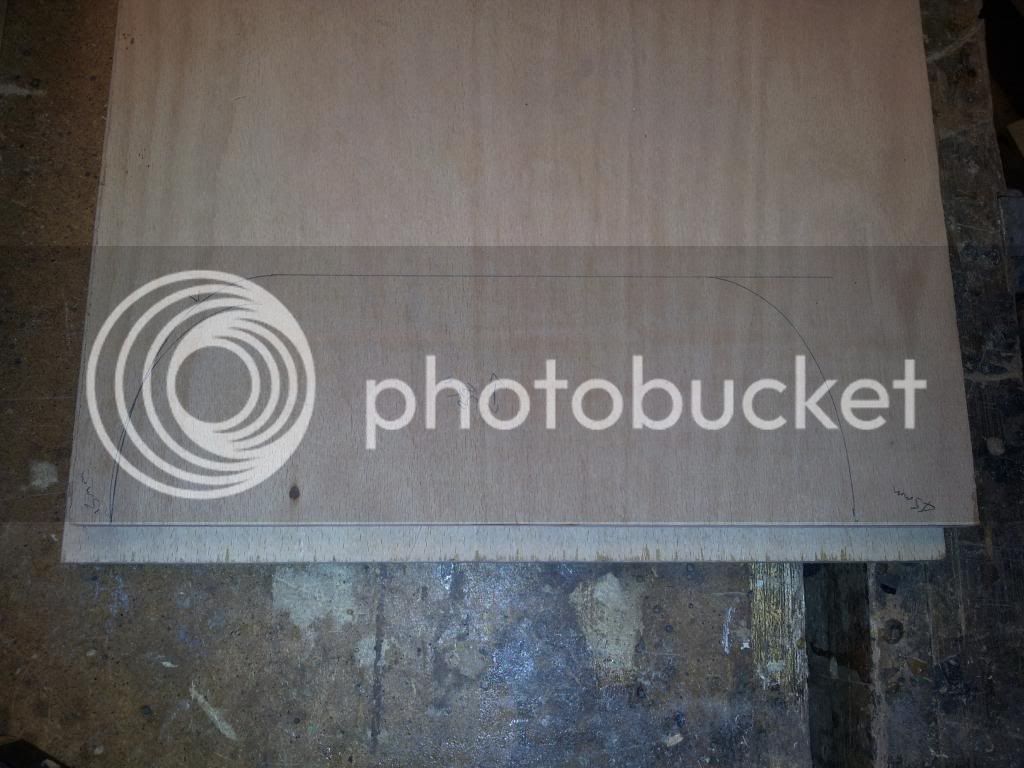

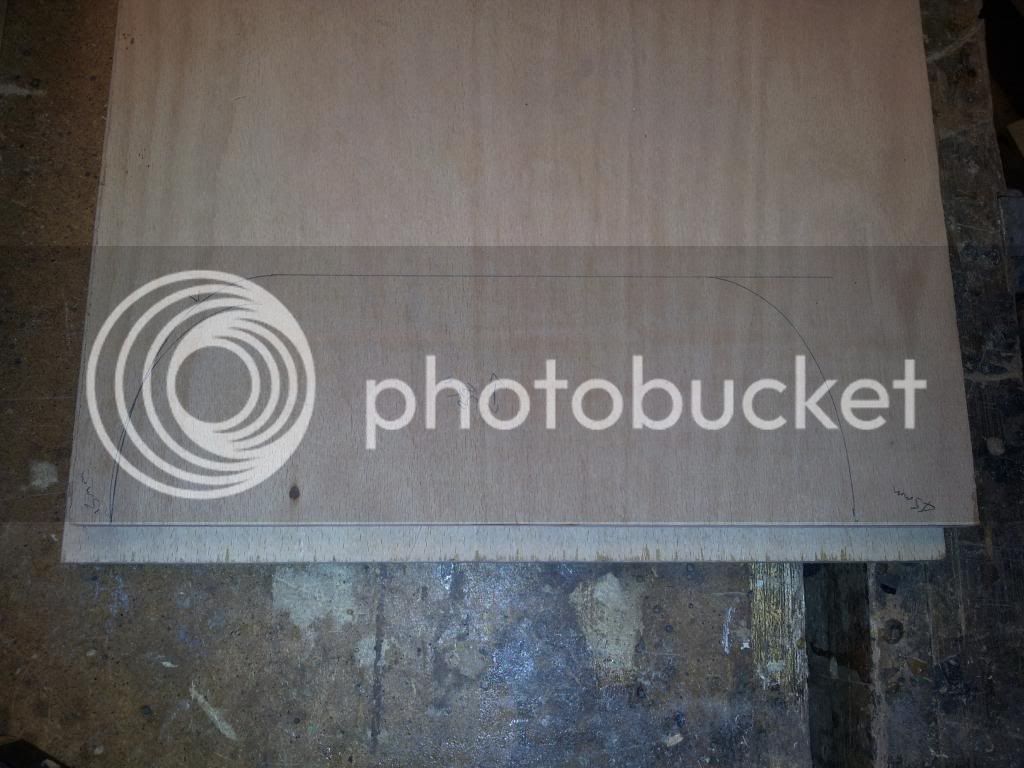

First up 2 pieces of 12mm ply cut to the same size and a piece of pine i had lying around.

Then cut the pine into strips for the top and bottoms.

Then a quick lick over the sawn edges with my 5 1/2

Then using my french curve, i layed out some curves at the top to allow for the saw handles. As i like things to match, i made a similar one for the bottom.

I then clamped the pieces of ply together and cut out the sections with my jigsaw.

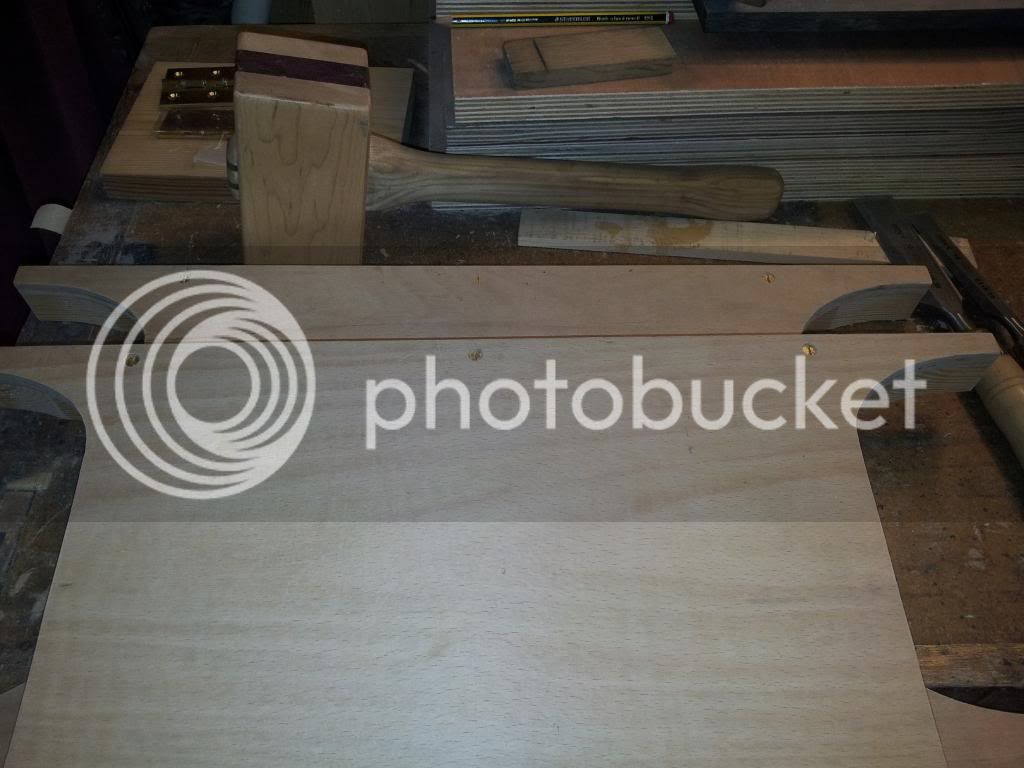

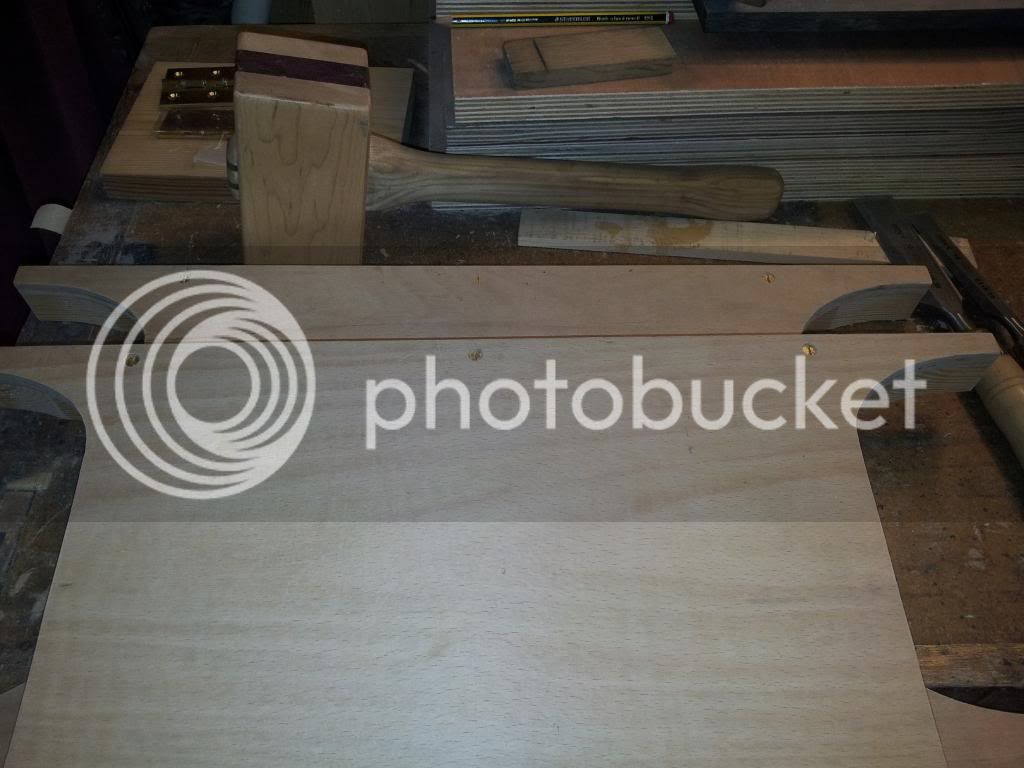

Then i glued/ screwed the timbers to the ply.

I then marked out for the 3'' brass butt hinges - all i had lying around. Well apart from some 4'' stainless fire door hinges. :lol:

Hinges chopped out.

Then after setting up the router table with pattern bit. Routed the top timbers flush with the ply.

Then finally, screwed the hinges to the base.

So there we have one saw vice. I will probably add some horizontal battens about half way down to form lips so it sits on the bench / vice top.

Just need to get some leather to line vice cheeks with to grip the saw better.

Further to this thread.

dovetail-saw-restoration-wip-t76516.html

A saw vice/ chop is needed, so while awaiting drill bits i thought i would knock one up.

It is sort of based on what is called/ referred to as the Lie Nielsen saw vice.

So using scraps of ply and pine i started it.

First up 2 pieces of 12mm ply cut to the same size and a piece of pine i had lying around.

Then cut the pine into strips for the top and bottoms.

Then a quick lick over the sawn edges with my 5 1/2

Then using my french curve, i layed out some curves at the top to allow for the saw handles. As i like things to match, i made a similar one for the bottom.

I then clamped the pieces of ply together and cut out the sections with my jigsaw.

Then i glued/ screwed the timbers to the ply.

I then marked out for the 3'' brass butt hinges - all i had lying around. Well apart from some 4'' stainless fire door hinges. :lol:

Hinges chopped out.

Then after setting up the router table with pattern bit. Routed the top timbers flush with the ply.

Then finally, screwed the hinges to the base.

So there we have one saw vice. I will probably add some horizontal battens about half way down to form lips so it sits on the bench / vice top.

Just need to get some leather to line vice cheeks with to grip the saw better.