sploo

Somewhat extinguished member

I recently spotted what looked to be a war production Stanley No 4 1/2 on fleaBay, and managed to get it for a very good price. There was a lot of rust. Here it is against my 1960s No 4 1/2:

The blade, cap iron and frog were clearly very corroded, but it mostly appeared to be surface rust:

Stripped down however, the japanning looked to be in excellent condition (better than my 1960s version):

I guess you can see what shape of frog the blade's been sitting on!:

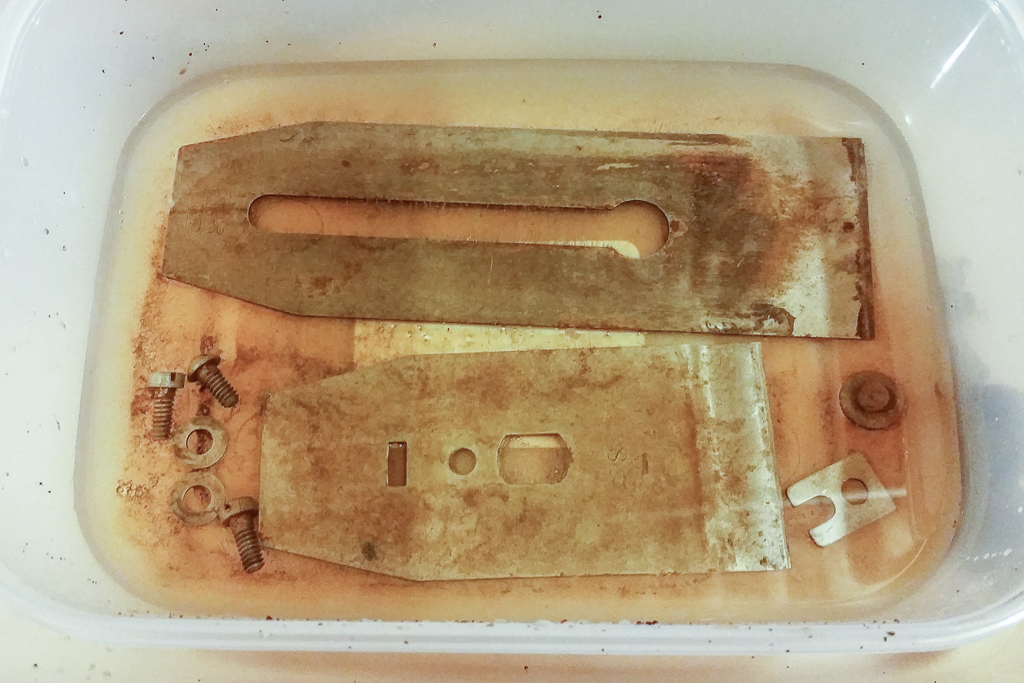

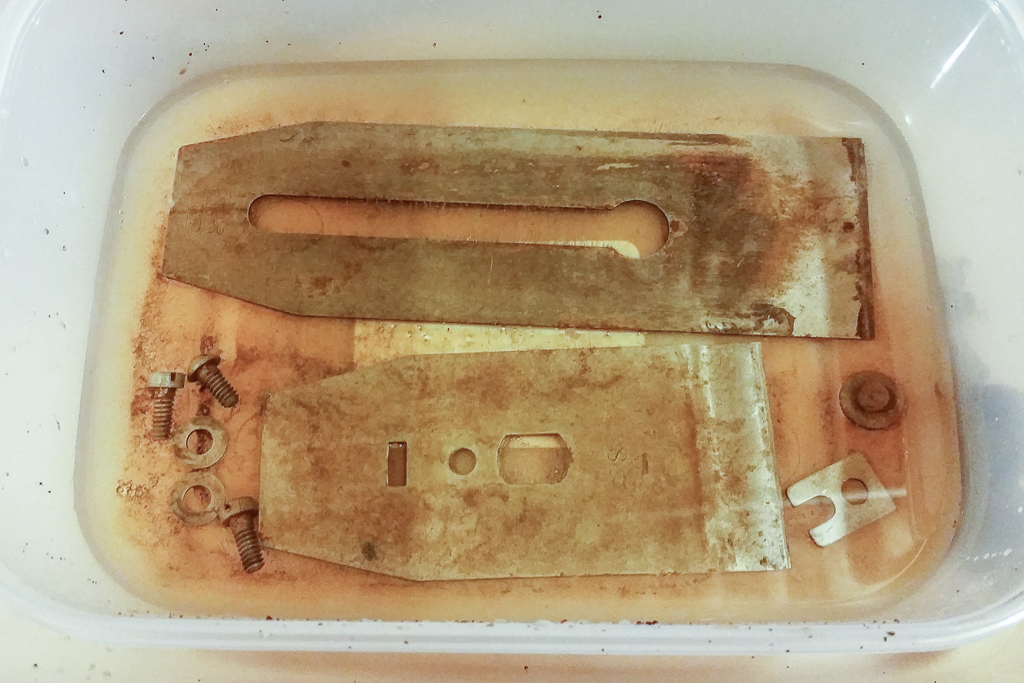

Being too cheap to buy a tub of Evapo-Rust, I came across a suggestion of using white vinegar with salt (apparently the salt increases the acidity). I thought I'd give it a go.

I couldn't find white vinegar in Tesco, but apparently distilled vinegar is similar (if usually a lower acidity). One 568ml bottle with 30 grams of salt was enough to submerge a number of rusty parts. I didn't want to risk the frog or sole as I understand it may affect the japanning.

Almost immediately I started to see some small bubbles:

24 hours later... it didn't look any different (albeit with more bubbles):

However, on taking the parts out and giving them a fairly gentle rub with 0000 steel wool the rust just wiped off. The heavily corroded Stanley stamp on the blade was easy to see (it was the sort of thing that might have partly been lost with heavy sanding). I turned the parts over and put them back in. 24 hours later it looked like this:

I'm not too sure the next 24 hours did much TBH, but it doesn't look to have caused damage. I then washed the parts off and put them in ~568ml of water mixed with 30 grams of bicarbonate of soda (baking soda) and left them for 10 minutes. According to the instructions I found this will neutralise the acid and prevent the metal continuing to be attacked:

I then rinsed the parts off, dried them with a paper towel, and put them in a fan oven at 50C for 5 minutes (I figured a bit of warm moving air would get them properly dry before any rust could develop).

Blade sharpened and cap iron polished:

I used Liberon Rust Remover on the frog and sole, with several applications. That worked very well on the lateral adjustment lever. The frog face and sole were flattened on 120 grit paper (I temporarily put the plane together to flatten the sole). Note that these images seem to show blue spots on the sole - it's actually white highlights that have gone a strange colour (some oddity between my phone's camera and Adobe Lightroom):

I was going to replace the brass/plastic depth nut with a spare, but it's come up really nice so I might leave it (honing compound on a leather strop got it shiny). The handles look very good too, so I'm tempted to fix them up rather than use replacements as that'll keep the plane original.

Oh, the blade and cap iron were obviously given a liberal wipe with oil, as were all the screws and washers and lateral lever. The frog and sole got a couple of applications of Liberon Lubricating Wax.

The slightly thicker sole casting (see the final picture above) and plastic depth nut are indicative of a war model, though interestingly, it weighs a tiny bit less than my 1960s No 4 1/2 (approx 2.1kg vs 2.2kg).

I don't think it must have been used much (given the full length blade and japanning), and cuts now beautifully.

As for the salt and vinegar - I think it's worth using. It certainly saved some time, and it's obviously very cheap. I bought several bottles, thinking I'd need more. Lucky really, 'cause there's (what I'm hoping is) a pre-war No 4 making it's way to me in the post :wink:

The blade, cap iron and frog were clearly very corroded, but it mostly appeared to be surface rust:

Stripped down however, the japanning looked to be in excellent condition (better than my 1960s version):

I guess you can see what shape of frog the blade's been sitting on!:

Being too cheap to buy a tub of Evapo-Rust, I came across a suggestion of using white vinegar with salt (apparently the salt increases the acidity). I thought I'd give it a go.

I couldn't find white vinegar in Tesco, but apparently distilled vinegar is similar (if usually a lower acidity). One 568ml bottle with 30 grams of salt was enough to submerge a number of rusty parts. I didn't want to risk the frog or sole as I understand it may affect the japanning.

Almost immediately I started to see some small bubbles:

24 hours later... it didn't look any different (albeit with more bubbles):

However, on taking the parts out and giving them a fairly gentle rub with 0000 steel wool the rust just wiped off. The heavily corroded Stanley stamp on the blade was easy to see (it was the sort of thing that might have partly been lost with heavy sanding). I turned the parts over and put them back in. 24 hours later it looked like this:

I'm not too sure the next 24 hours did much TBH, but it doesn't look to have caused damage. I then washed the parts off and put them in ~568ml of water mixed with 30 grams of bicarbonate of soda (baking soda) and left them for 10 minutes. According to the instructions I found this will neutralise the acid and prevent the metal continuing to be attacked:

I then rinsed the parts off, dried them with a paper towel, and put them in a fan oven at 50C for 5 minutes (I figured a bit of warm moving air would get them properly dry before any rust could develop).

Blade sharpened and cap iron polished:

I used Liberon Rust Remover on the frog and sole, with several applications. That worked very well on the lateral adjustment lever. The frog face and sole were flattened on 120 grit paper (I temporarily put the plane together to flatten the sole). Note that these images seem to show blue spots on the sole - it's actually white highlights that have gone a strange colour (some oddity between my phone's camera and Adobe Lightroom):

I was going to replace the brass/plastic depth nut with a spare, but it's come up really nice so I might leave it (honing compound on a leather strop got it shiny). The handles look very good too, so I'm tempted to fix them up rather than use replacements as that'll keep the plane original.

Oh, the blade and cap iron were obviously given a liberal wipe with oil, as were all the screws and washers and lateral lever. The frog and sole got a couple of applications of Liberon Lubricating Wax.

The slightly thicker sole casting (see the final picture above) and plastic depth nut are indicative of a war model, though interestingly, it weighs a tiny bit less than my 1960s No 4 1/2 (approx 2.1kg vs 2.2kg).

I don't think it must have been used much (given the full length blade and japanning), and cuts now beautifully.

As for the salt and vinegar - I think it's worth using. It certainly saved some time, and it's obviously very cheap. I bought several bottles, thinking I'd need more. Lucky really, 'cause there's (what I'm hoping is) a pre-war No 4 making it's way to me in the post :wink: