devonwoody

Established Member

I have never seen one of these joints used on the forums but I suspect others have used this idea.

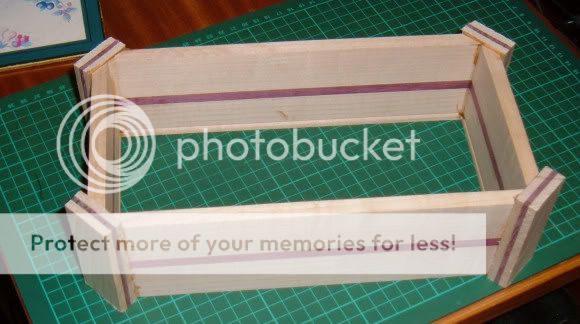

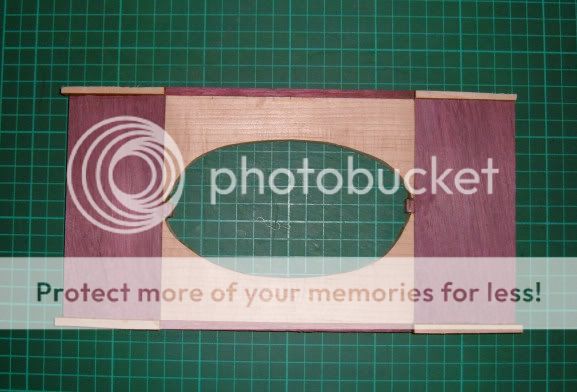

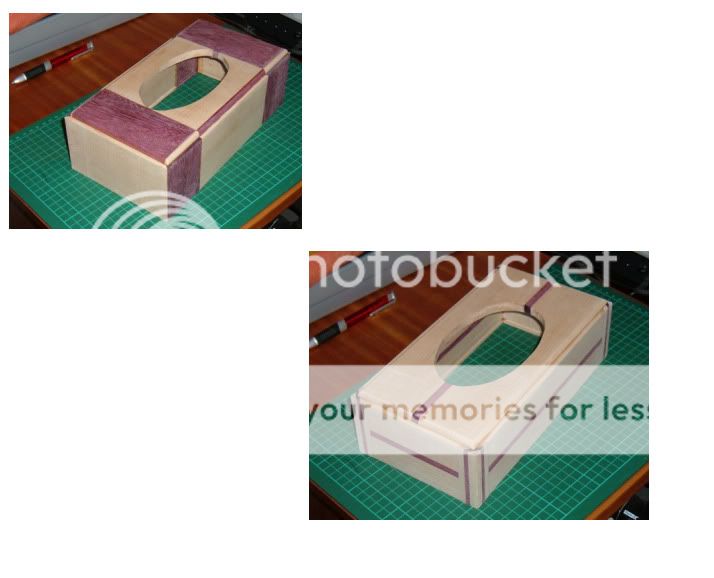

The mitres instead of forming their only 90% corner face outwards and a corner block is going to be used to compensate.

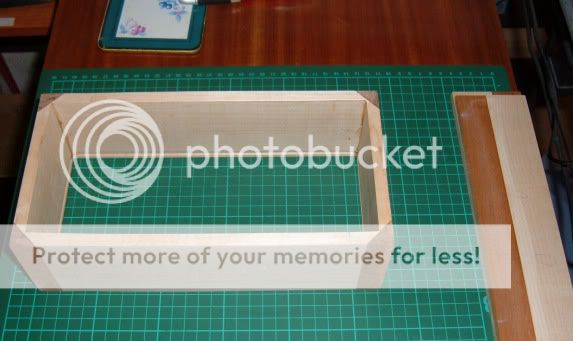

A nice piece of maple to be resawn.

Maple machined up and normal mitres made on my jig. Also found a length of I think is Utile from 40 years ago.

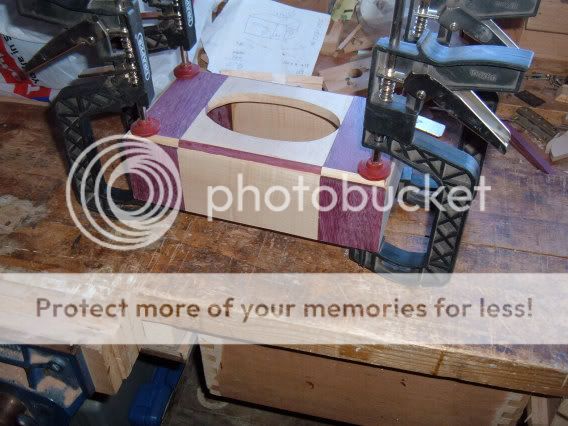

The utile was cut to shape on the tablesaw with a 45% rip cut and cut to length then glued to reverse the mitres.

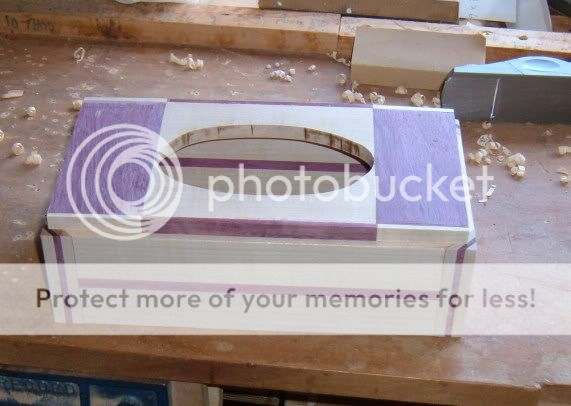

Did a bit of overtime last evening

The mitres instead of forming their only 90% corner face outwards and a corner block is going to be used to compensate.

A nice piece of maple to be resawn.

Maple machined up and normal mitres made on my jig. Also found a length of I think is Utile from 40 years ago.

The utile was cut to shape on the tablesaw with a 45% rip cut and cut to length then glued to reverse the mitres.

Did a bit of overtime last evening